Triple-hybrid yolk-shell structured mesoporous organic silica and preparation method thereof

A technology based on organic silicon oxide and triethoxy silicon, which is applied in the field of nanomaterials, can solve problems such as singleness, and achieve the effect of low cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

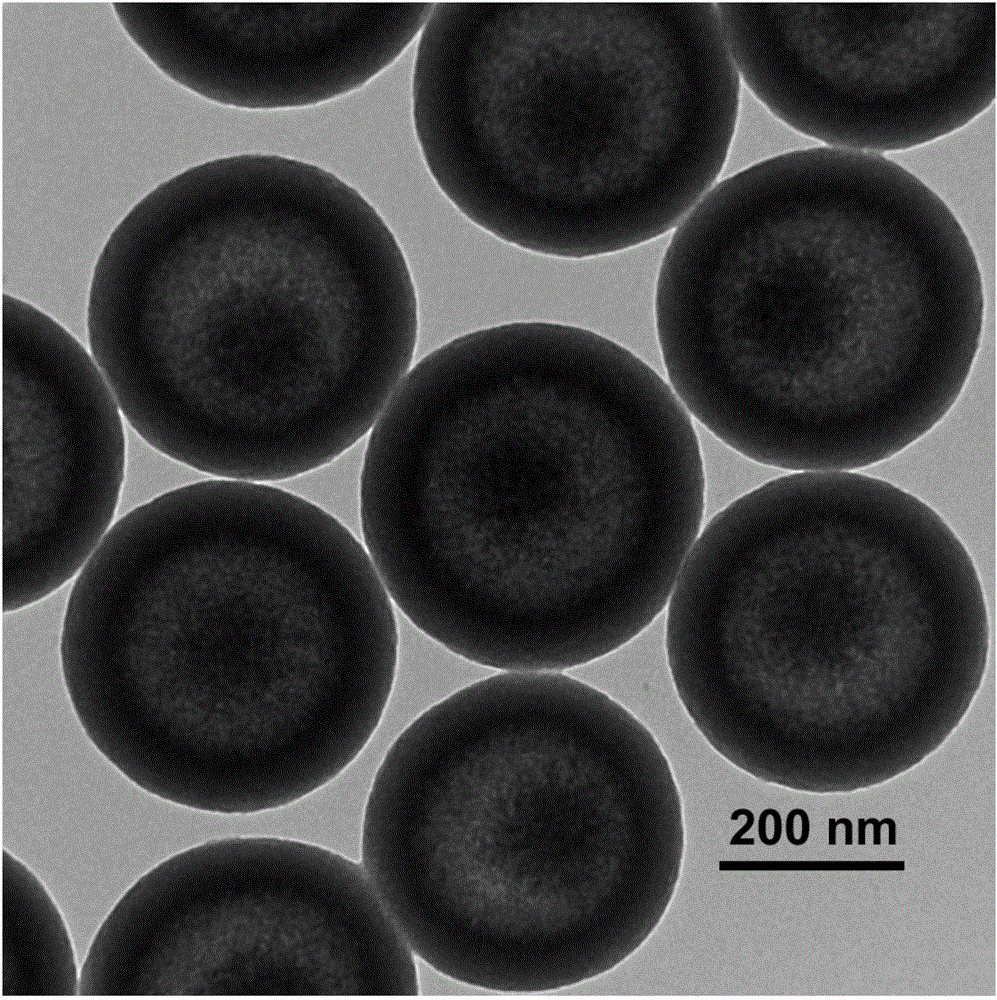

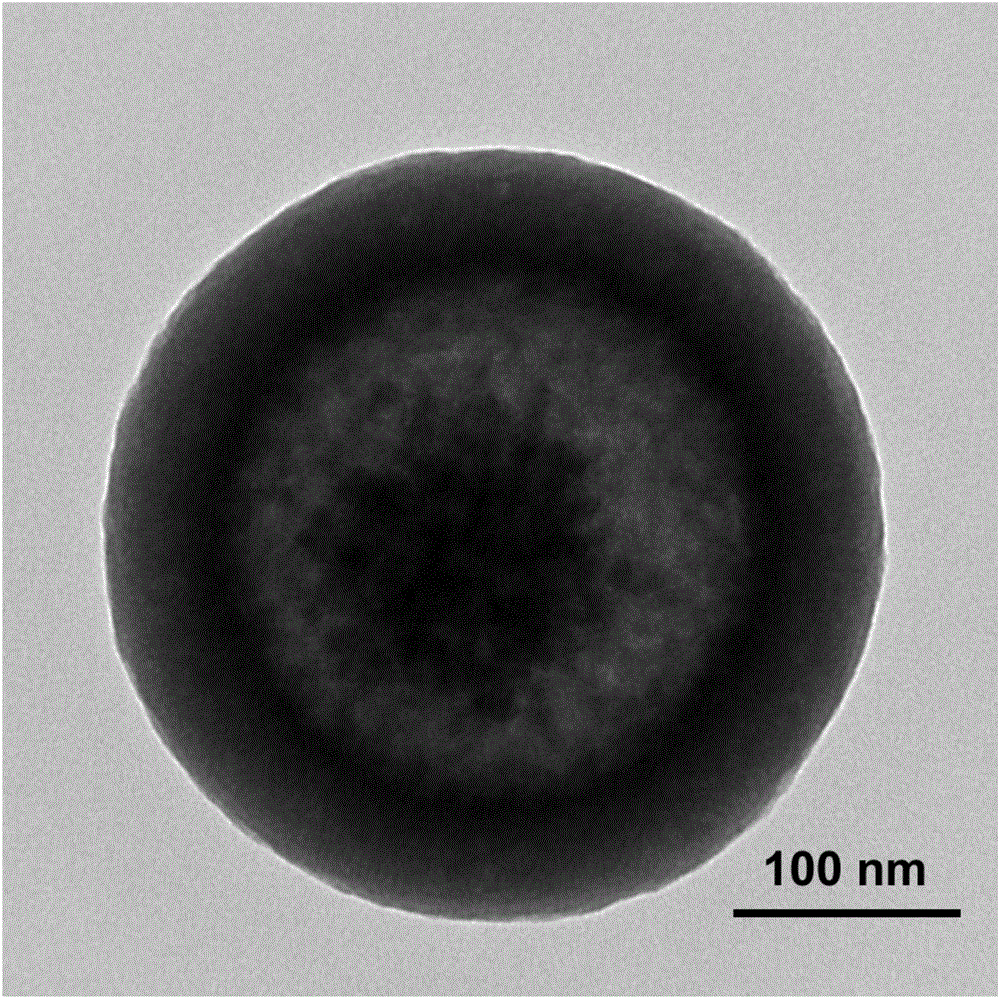

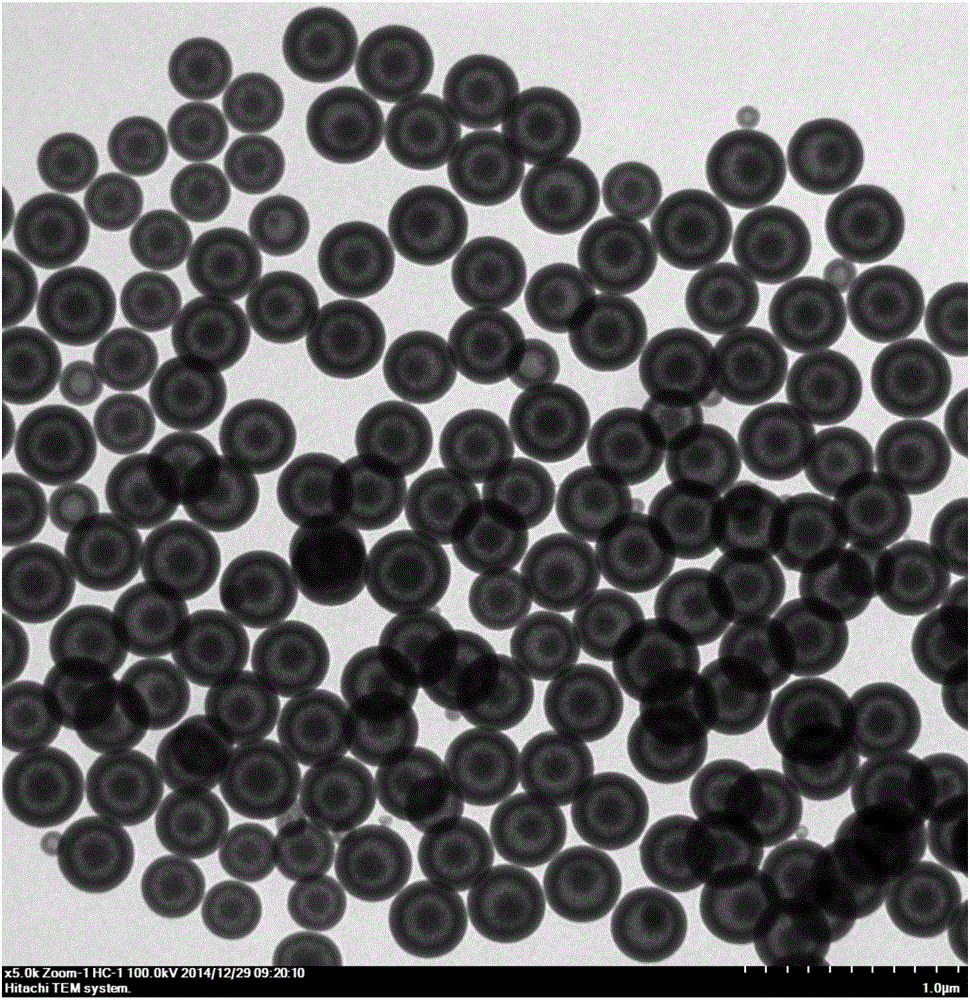

Image

Examples

Embodiment 1

[0033] (1) Mix 1ml of concentrated ammonia water (the NH contained in the concentrated ammonia water 3The mass percent concentration is 25%) mixed with 30ml ethanol and 75ml water, then 0.16g hexadecyltrimethylammonium bromide solution was added to the mixed solution, and 0.125ml orthosilicon Acid tetraethyl ester, 0.4ml of 1,2-bis(triethoxysilyl)ethane, 0.1ml of bis[γ-(triethoxysilyl)propyl]tetrasulfide and 0.1ml of 1, A mixture of 2-bis(triethoxysilyl)benzene was added to the aqueous alcohol solution, namely tetraethylorthosilicate, 1,2-bis(triethoxysilyl)ethane, bis[γ-( The molar ratio of triethoxysilyl) propyl] tetrasulfide and 1,2-bis(triethoxysilyl) benzene, surfactant, water and ethanol is 1:1.9:0.36:0.45:0.8: 7455:922, reacted for 12h to obtain a white solution;

[0034] (2) Centrifuge the white solution obtained in step (1), wash it with water, and transfer it to water to prepare an organic silicon oxide dispersion, and place it at 70°C for 24 hours;

[0035] (3) T...

Embodiment 2

[0038] (1) Mix 1ml of concentrated ammonia water (the NH contained in the concentrated ammonia water 3 The mass percent concentration is 25%) mixed with 33ml ethanol and 120ml water, then 1.3g hexadecyltrimethylammonium bromide was dissolved in the mixed solution, and 0.125ml orthosilicon Acid tetraethyl ester, 0.62ml of 1,2-bis(triethoxysilyl)ethane, 0.28ml of bis[γ-(triethoxysilyl)propyl]tetrasulfide and 0.22ml of 1, A mixture of 2-bis(triethoxysilyl)benzene was added to the aqueous alcohol solution, namely tetraethylorthosilicate, 1,2-bis(triethoxysilyl)ethane, bis[γ-( The molar ratio of triethoxysilyl)propyl]tetrasulfide and 1,2-bis(triethoxysilyl)benzene, surfactant, water and ethanol is 1:3.0:1:1.0:6.5: 12000:1000, reacted for 24h, and obtained a white solution;

[0039] (2) Centrifuge the white solution obtained in step (1), wash it with water, and transfer it to water to prepare an organic silicon oxide dispersion, and place it at 50°C for 12 hours;

[0040] (3) The...

Embodiment 3

[0043] (1) Mix 1ml of concentrated ammonia water (the NH contained in the concentrated ammonia water 3 The mass percent concentration is 25%) mixed with 30ml ethanol and 95ml water, then 0.16g hexadecyltrimethylammonium bromide was dissolved in the mixed solution, and 0.125ml orthosilicon Tetraethyl ester, 0.2ml of 1,2-bis(triethoxysilyl)ethane, 0.1ml of bis[γ-(triethoxysilyl)propyl]tetrasulfide and 0.1ml of 1, A mixture of 2-bis(triethoxysilyl)benzene was added to the aqueous alcohol solution, namely tetraethylorthosilicate, 1,2-bis(triethoxysilyl)ethane, bis[γ-( The molar ratio of triethoxysilyl) propyl] tetrasulfide and 1,2-bis (triethoxysilyl) benzene, surfactant, water and ethanol is 1:0.97:0.36:0.45:0.8: 7455:922, reacted for 24h to obtain a white solution;

[0044] (2) Centrifuge the white solution obtained in step (1), wash it with water, and transfer it to water to prepare an organic silicon oxide dispersion, and place it at 40°C for 24 hours;

[0045] (3) The reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com