Low-temperature quick-forming three-dimensional printing collagen silk fibroin material

A silk fibroin and three-dimensional printing technology, applied in medical science, prosthesis, etc., can solve the problems of poor three-dimensional porous network structure, poor biomechanical properties, and structural instability, and achieve good biocompatibility and mechanical properties The effect of good performance, good properties and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 collagen / silk fibroin material

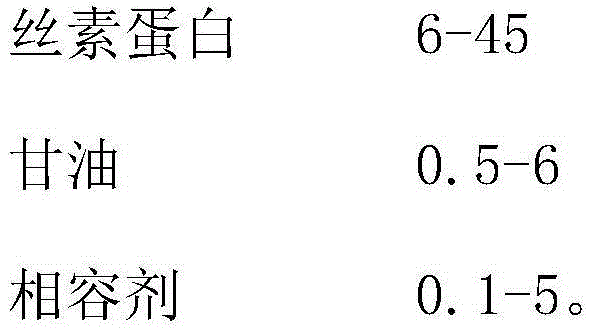

[0028]

[0029]

[0030] (1) Preparation of collagen solution

[0031] Tender pigskin or beef tendon is used as collagen biomaterial, cleaned and degreased with NaOH solution of pH 8.0-12, dissolved in acetic acid solution of pH 5.0-6.5 after degreasing, mixed with compound protease, collagen and The mass ratio of the composite protease is 500-1000:1, and the stirring is continued overnight;

[0032] Centrifuge, collect the supernatant, add NaCl, stir, collect the precipitate, add acetic acid, repeat the operation, repeat the centrifugation, collect the supernatant, add NaCl, stir, collect the precipitate, add the step of acetic acid 3 times, the obtained precipitate For collagen, dissolve collagen in 0.01-0.1% acetic acid solution to obtain 1-3% collagen solution.

[0033] (2) Preparation of silk fibroin solution

[0034] Take the silk, put the silk raw material into 80-120℃ Na 2 CO 3 In the so...

Embodiment 2

[0037] Example 2 Printing of Collagen / Silk Fibroin Scaffold Material

[0038](1) The solution of the biological material obtained in Example 1 is placed in the material storage of the printer; the diameter of the needle of the bioprinter is 60-400 μm, the number of needles is 6-16, the printing layer from the needle to the base is 100-300 μm, and the printing speed 2-10mm / sec, the printing gap is 100μm-400μm, and the temperature is set at -30℃-5℃.

[0039] (2) The scaffold material to be printed 60 Co sterilized and sterilized, put in 10 6 —10 8 / ml neural stem cell culture medium, cultured for 8-14 days.

[0040] (3) Rat craniocerebral injury model is prepared, and the prepared scaffold material containing cells is placed into the injury site to form local cell directional differentiation, which can be evenly distributed and can replace the biological scaffold material.

Embodiment 3

[0041] The preparation of embodiment 3 collagen / silk fibroin material

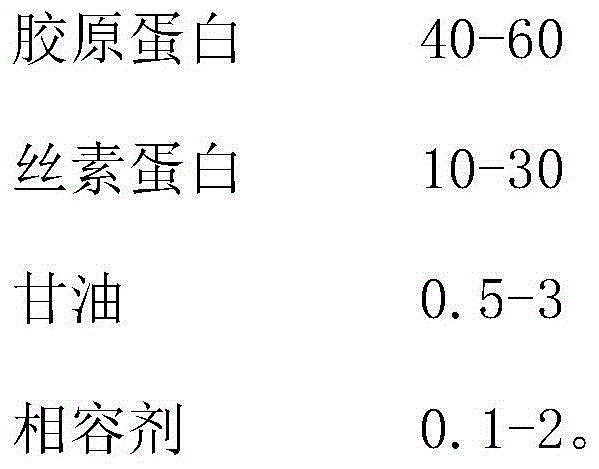

[0042]

[0043] (1) Preparation of collagen solution

[0044] Tender pigskin or beef tendon is used as collagen biomaterial, cleaned and degreased with NaOH solution of pH 8.0-12, dissolved in acetic acid solution of pH 5.0-6.5 after degreasing, mixed with compound protease, collagen and The mass ratio of the composite protease is 500-1000:1, and the stirring is continued overnight;

[0045] Centrifuge, collect the supernatant, add NaCl, stir, collect the precipitate, add acetic acid, centrifuge, collect the supernatant, add NaCl, stir, collect the precipitate, add acetic acid, repeat the operation Repeat the centrifugation, collect the supernatant, add NaCl , stirring, collecting the precipitate, and adding acetic acid for 4 times, the precipitate obtained is collagen, and the collagen is dissolved in 0.01-0.1% acetic acid solution to obtain a 1-3% collagen solution.

[0046] (2) Preparation of silk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com