Micro-nano composite glaze

A technology of micro-nano composite and glaze, which is applied in the field of ceramic glaze, can solve the problem of less nano-composite glaze, achieve good curing effect, save fuel cost, and have good effect of water reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

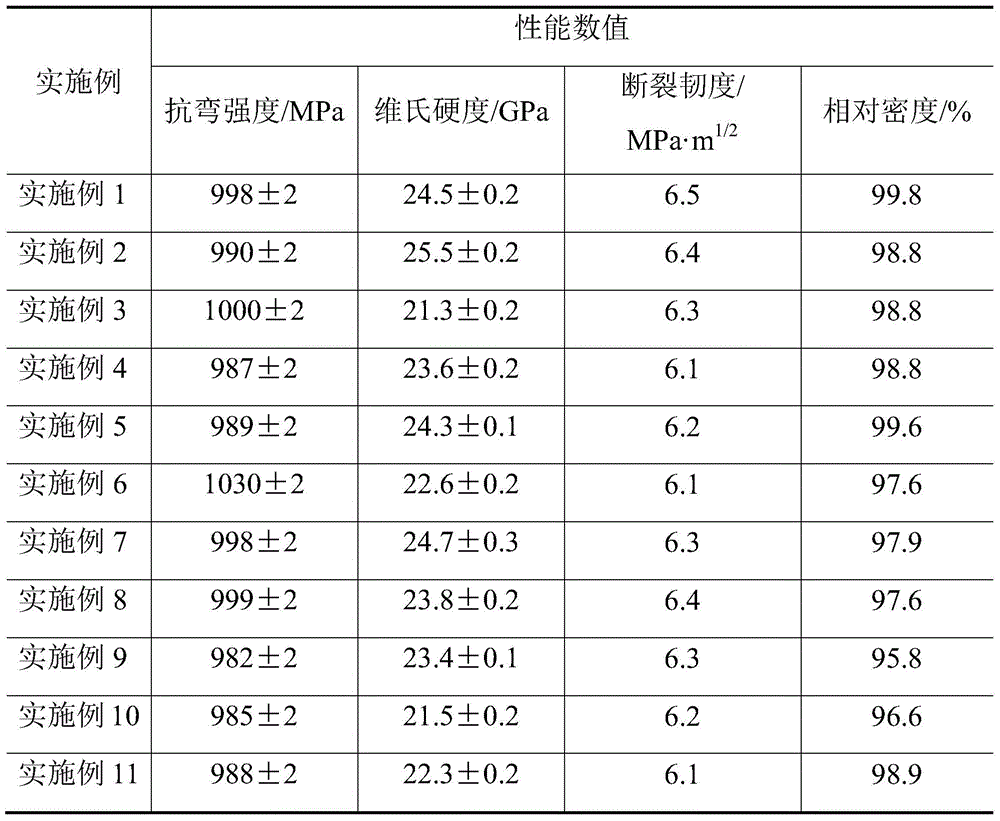

Examples

Embodiment 1

[0024] A micro-nano composite glaze, which is composed of the following raw materials in parts by weight: micron α-Al 2 o 3 40 parts, nano TiO 2 7 parts, micron Ni8 parts, nano ZrO 2 5 parts, 56 parts of nano-TiC, 8 parts of mullite, 27 parts of kaolin, 39 parts of fused corundum, 15 parts of micro-silica powder, 3 parts of sodium hexametaphosphate, 3 parts of zinc oxide, 15 parts of zirconium carbide, silicon nitride 8 parts, 8 parts of yttrium carbonate, 9 parts of black diamond powder.

[0025] Among them, micron α-Al 2 o 3 The particle size is 55-65nm, and the average particle size is 58±1nm; nano-TiO 2 The particle size is 40-50nm, the average particle size is 45±1nm; nano ZrO 2 The particle size of nano-TiC is 65-75nm, and the average particle size is 70±1nm; the particle size of nano-TiC is 65-75nm, and the average particle size is 72±1nm.

Embodiment 2

[0027] A micro-nano composite glaze, which is composed of the following raw materials in parts by weight: micron α-Al 2 o 3 47 parts, nano TiO 2 8 parts, micron Ni3 parts, nano ZrO 2 6 parts, 55 parts of nano-TiC, 6 parts of mullite, 20 parts of kaolin, 50 parts of fused corundum, 15 parts of silica micropowder, 4 parts of sodium hexametaphosphate, 3 parts of zinc oxide, 8 parts of zirconium carbide, silicon nitride 3 parts, 3 parts of yttrium carbonate, 7 parts of black diamond powder.

[0028] Among them, micron α-Al 2 o 3 The average particle size is 58±1nm; Nano TiO 2 The average particle size is 46±1nm; nanometer ZrO 2 The average particle size is 70±1nm; the average particle size of nano-TiC is 70±1nm.

Embodiment 3

[0030] A micro-nano composite glaze, which is composed of the following raw materials in parts by weight: micron α-Al 2 o 3 32 parts, nano TiO 2 6 parts, micron Ni7 parts, nano ZrO2 9 parts, 60 parts of nano-TiC, 8 parts of mullite, 22 parts of kaolin, 31 parts of fused corundum, 17 parts of silicon dioxide micropowder, 6 parts of sodium hexametaphosphate, 8 parts of zinc oxide, 12 parts of zirconium carbide, silicon nitride 8 parts, 8 parts of yttrium carbonate, 14 parts of black diamond powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com