Slump-retaining water-reducing polycarboxylic acid water reducing agent and low-temperature quick preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of building materials, can solve problems such as dependence, and achieve the effects of good workability, wide adaptability and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

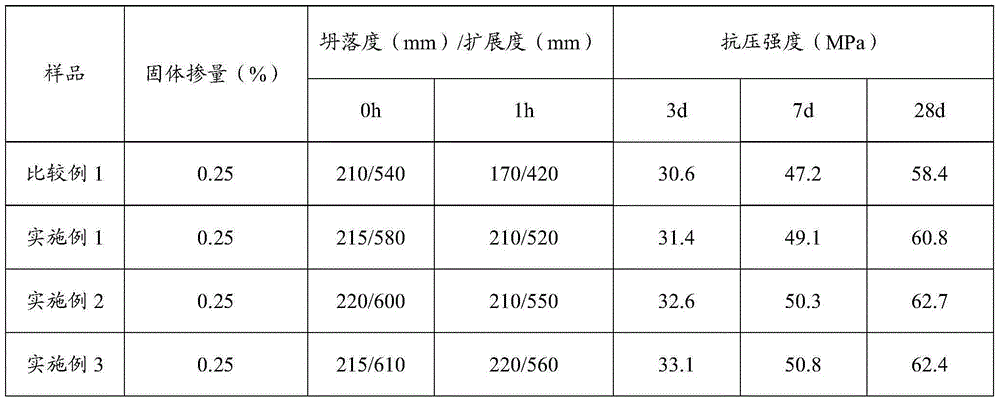

Embodiment 1

[0029] 1) Prepare solution A with 15 parts of acrylic acid and 30 parts of water; 0.4 parts of sodium formaldehyde sulfoxylate, 0.1 part of sodium sulfite, 0.1 part of 2-carboxy-2-sulfinic acid disodium salt and 30 parts of water Prepare solution B with a pH value of 7-9; prepare solution C with 1 part of chain transfer agent thioglycolic acid and 30 parts of water;

[0030] 2) Add 100 parts of isopentenyl polyoxyethylene ether (TPEG) (molecular weight 1200-4800), 2 parts of acrylic acid, 2 parts of oxidant hydrogen peroxide and 40 parts of water into the reaction kettle, mix to obtain a pH value of 3 ~6 mixed solution, adjust the reaction temperature to 60°C, stir and dissolve; first add solution B and solution C dropwise to the mixed solution at the same time, after 10 minutes, continue to add solution B and solution C Add solution A dropwise, wherein the dropping rate of the first 2 / 3 of solution A is 0.1g / s~0.2g / s, and the dropping rate of the last 1 / 3 of solution A is 0.0...

Embodiment 2

[0033] 1) Prepare solution A with 7 parts of acrylic acid, 3 parts of hydroxypropyl acrylate and 20 parts of water; prepare 0.2 parts of sodium formaldehyde sulfoxylate as a reducing agent, 0.1 part of succulent and 20 parts of water to make the pH value 7-9 Solution B; 0.2 parts of chain transfer agent mercaptoacetic acid, 0.1 part of sodium methyl propyl sulfonate and 20 parts of water are prepared into solution C;

[0034] 2) Mix 20 parts of hydroxybutyl vinyl ether polyoxyethylene ether (VPEG), 80 parts of isopentenyl polyoxyethylene ether (molecular weight is 1200-4800), 2 parts of acrylic acid, 1 part of methacrylic acid, 1 Add one part of oxidant hydrogen peroxide and 70 parts of water into the reaction kettle, mix to obtain a mixed solution with a pH value of 3 to 6, adjust the reaction temperature to 30°C, and stir to dissolve; first drop solution B and solution C into the mixed solution at the same time , after 20 minutes of dropping, start to drop solution A while c...

Embodiment 3

[0037] 1) Prepare solution A with 6 parts of acrylic acid, 3 parts of methacrylic acid, 2 parts of hydroxyethyl acrylate and 20 parts of water; the reducing agent is 0.05 parts of sodium formaldehyde sulfoxylate, 0.15 parts of sodium sulfite, 0.05 parts of 2-carboxy-2 - Disodium sulfinic acid glycolate and 20 parts of water are prepared into a solution B with a pH value of 7 to 9; 0.2 parts of mercaptoacetic acid, 0.3 parts of mercaptopropionic acid and 20 parts of water are prepared into solution C as a chain transfer agent;

[0038]2) Mix 30 parts of hydroxybutyl vinyl ether polyoxyethylene ether, 70 parts of isopentenyl polyoxyethylene ether (all molecular weights are 1200 to 4800), 1 part of acrylic acid, 1 part of hydroxyethyl acrylate, and 0.5 parts of oxidizing agent Add sodium persulfate and 70 parts of water into the reaction kettle, mix to obtain a mixed solution with a pH value of 3-6, adjust the reaction temperature to 40°C, stir and dissolve; first add solution B a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com