Aspergillus niger granulating and leaching method of copper tailings

A technology for making Aspergillus niger and copper tailings, which is applied in the direction of improving process efficiency and can solve problems such as the influence of ore particle stability, contact reaction hindrance, multiple energy sources and materials, and achieve easy solid-liquid separation, fast leaching speed, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

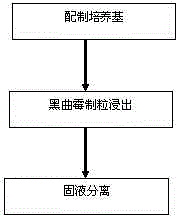

Method used

Image

Examples

Embodiment 1

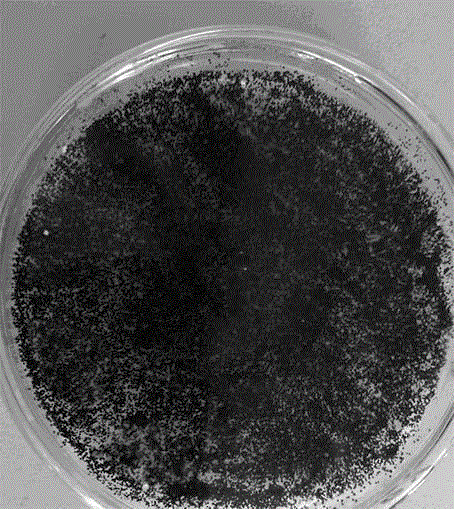

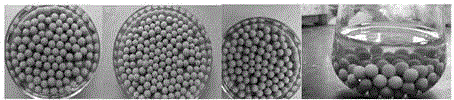

[0035] Take 5g copper tailings ore powder and place it in 100mL Aspergillus niger culture medium, inoculate 0.02% Aspergillus niger spore suspension (OD 600 =1.0) and then placed in a constant temperature culture shaker for leaching, the temperature of the shaker culture was controlled at 20°C, and the rotation speed was 200r / min. Mycelial balls wrapped with copper tailings appeared after 72 hours of culture, and the mycelial balls gradually increased with the extension of culture time. After 7 days of leaching, the average diameter of mycelial balls covering the tailings was 3.15mm, and the viscosity of the leachate was 1.15cP. The solid-liquid separation was carried out by funnel filtration, the copper content in the slag sample was measured, and the copper leaching rate was calculated to be 82.36%.

Embodiment 2

[0037] Take 5g copper tailings ore powder and place it in 100mL Aspergillus niger culture medium, inoculate 0.02% Aspergillus niger spore suspension (OD 600 =1.0) and then placed in a constant temperature culture shaker for leaching, the temperature of the shaker culture was controlled at 25°C, and the rotation speed was 200r / min. Mycelial balls wrapped with copper tailings appeared after 60 hours of culture, and the mycelial balls gradually increased with the extension of culture time. After 7 days of leaching, the average diameter of mycelial balls wrapped with copper tailings was 3.05 mm, and the viscosity of the leachate was 1.12 cP. After the slag was digested, the copper content in the slag sample was measured and the leaching rate of copper was calculated to be 86.18%.

Embodiment 3

[0039] Take 5g copper tailings ore powder and place it in 100mL Aspergillus niger culture medium, inoculate 0.02% Aspergillus niger spore suspension (OD 600 =1.0) and then placed in a constant temperature cultivating shaker for leaching, the temperature of the shaker was controlled to be 25°C, and the rotating speed was 120r / min. Mycelial balls wrapped with copper tailings appeared after 60 hours of culture, and the mycelial balls gradually increased with the extension of culture time. After 7 days of leaching, the average diameter of mycelial balls wrapped with copper tailings was 7.36 mm, and the viscosity of the leachate was 1.18 cP. After the slag was digested, the copper content in the slag sample was measured and the leaching rate of copper was calculated to be 75.39%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com