Macromolecule-based resistance type humidity sensing element and preparation method thereof

A moisture-sensitive component and polymer-based technology, applied in the direction of material resistance, can solve the problems of resistance-type polymer humidity sensors with unsatisfactory water resistance and loss of sensitive substances, and achieve high sensitivity, good stability, and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

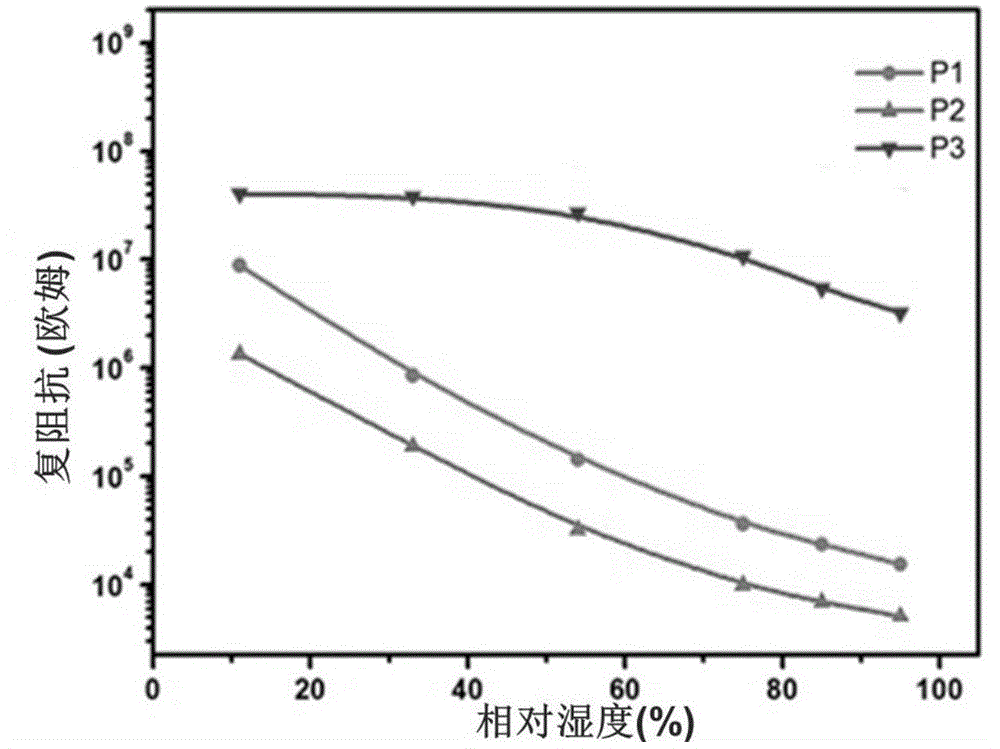

[0025] Preparation of P1 polymer elements

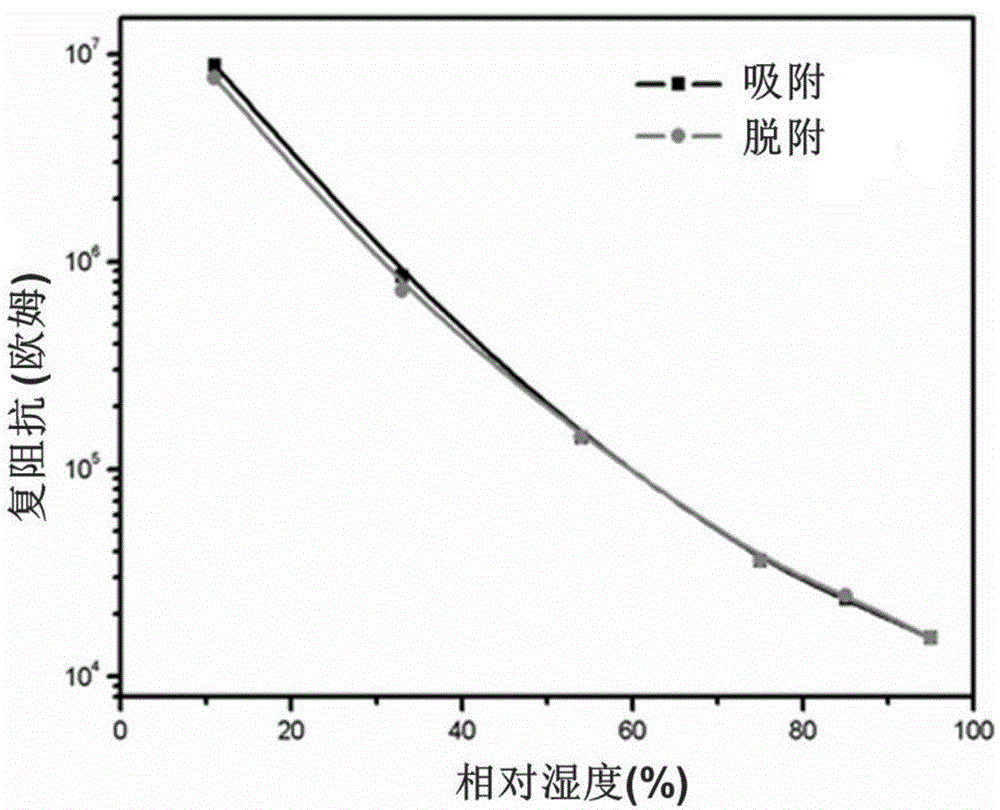

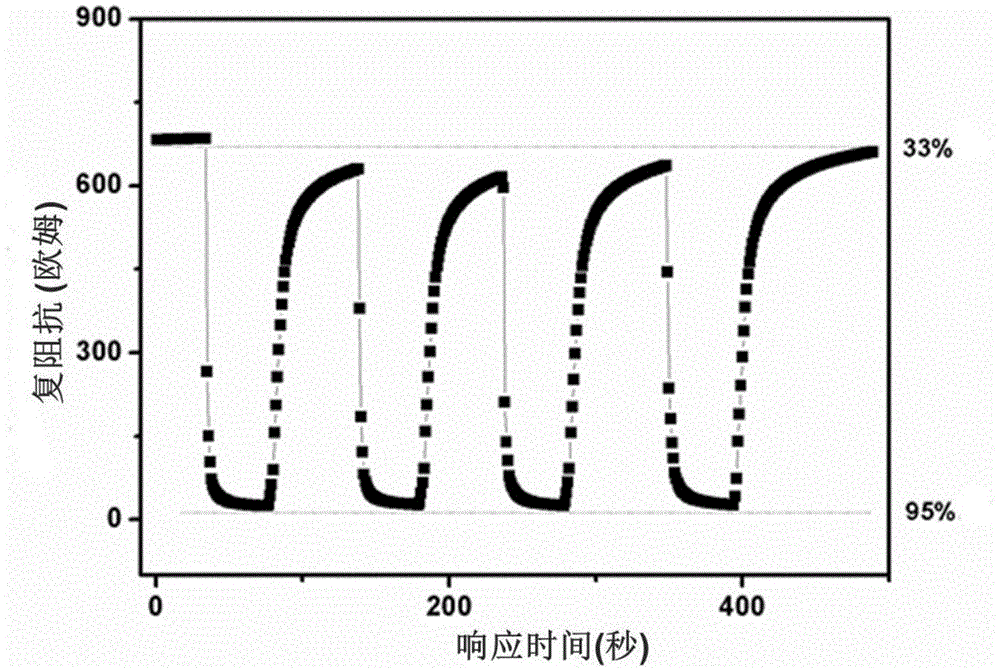

[0026] Octapropylmercaptooctasilsesquioxane (300.0mg, 294.7μmol), divinylbenzene (115.1mg, 884.2μmol), methacryloxyethyltrimethylammonium chloride (80wt% aqueous solution, 153.0mg, 589.4 μmol), benzoin dimethyl ether (6.0 mg, 23.6 μmol) were added into the reaction flask, and tetrahydrofuran (1 mL) was added to dissolve the reactant. After the reactants are evenly mixed, the carbon interdigitated electrodes (substrate area 5mm×8mm, four pairs of electrodes, electrode width 300μm, inter-finger spacing 350μm) are immersed in the solution for about 10 seconds, then taken out, and dried in the air for two minutes With ultraviolet light (120mJ / cm 2 ) was irradiated for 30 minutes to carry out polymerization, and the thickness of the obtained cross-linked humidity sensitive film was 28 μm, thereby preparing a polymer-based resistance type humidity sensitive element.

Embodiment 2

[0028] Preparation of P2 polymer elements

[0029] Octapropylmercaptooctasilsesquioxane (300.0 mg, 294.7 μmol), divinylbenzene (105.5 mg, 810.5 μmol), methacryloxyethyltrimethylammonium chloride (80 wt % aqueous solution, 191.3 mg, 736.8 μmol), benzoin dimethyl ether (6.0 mg, 23.6 μmol) were added into the reaction flask, and tetrahydrofuran (1 mL) was added to dissolve the reactant. After the reactants are evenly mixed, the carbon interdigitated electrodes (substrate area 5mm×8mm, four pairs of electrodes, electrode width 300μm, inter-finger spacing 350μm) are immersed in the solution for about 10 seconds, then taken out, and dried in the air for two minutes With ultraviolet light (120mJ / cm 2 ) was irradiated for 30 minutes to carry out polymerization, and the thickness of the obtained cross-linked humidity sensitive film was 25 μm, thereby preparing a polymer-based resistance type humidity sensitive element.

Embodiment 3

[0031] Preparation of P3 polymer elements

[0032] Octapropylmercaptooctasilsesquioxane (300.0 mg, 294.7 μmol), divinylbenzene (124.7 mg, 957.9 μmol), methacryloyloxyethyltrimethylammonium chloride (80 wt % aqueous solution, 114.8 mg, 442.1 μmol), benzoin dimethyl ether (6.0 mg, 23.6 μmol) were added into the reaction flask, and tetrahydrofuran (1 mL) was added to dissolve the reactant. After the reactants are evenly mixed, the carbon interdigitated electrodes (substrate area 5mm×8mm, four pairs of electrodes, electrode width 300μm, inter-finger spacing 350μm) are immersed in the solution for about 10 seconds, and then put out after drying in the air for two minutes. With ultraviolet light (120mJ / cm 2 ) was irradiated for 30 minutes to carry out polymerization, and the thickness of the obtained cross-linked humidity sensitive film was 25 μm, thereby preparing a polymer-based resistance type humidity sensitive element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com