Method for improving the performance of gallium nitride laser

A GaN-based, laser technology, used in lasers, laser components, semiconductor lasers, etc., can solve problems such as aggravating negative effects, hindering hole injection, and reducing effective electron barrier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

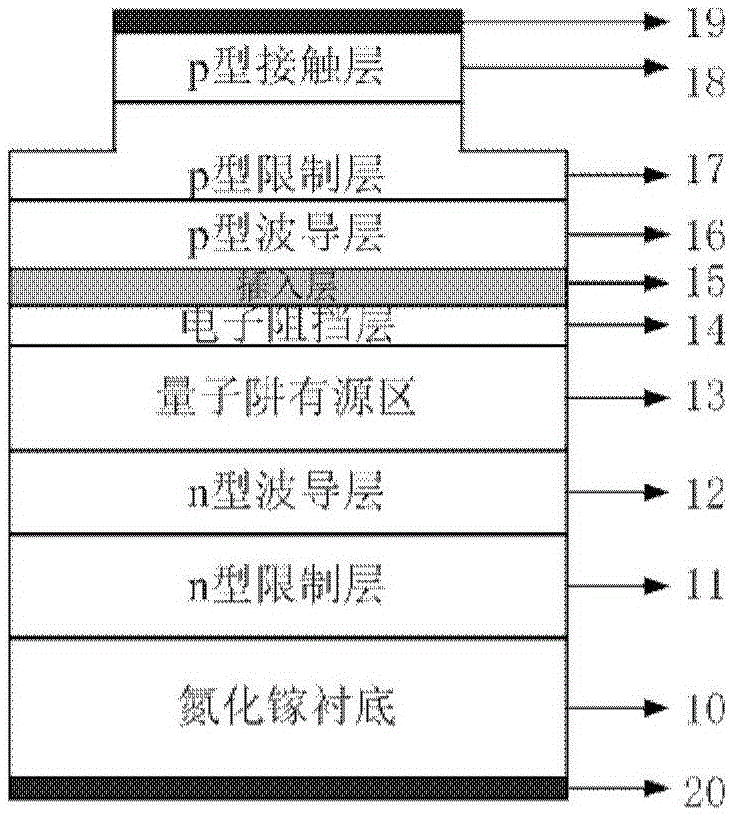

[0021] The present invention proposes a GaN-based laser, which includes:

[0022] There is an insertion layer between the electron blocking layer and the P-type waveguide layer of the GaN-based laser;

[0023] The material of the insertion layer is doped indium gallium nitrogen, its thickness is 2-15 nm, and the indium composition is 0.005-0.05.

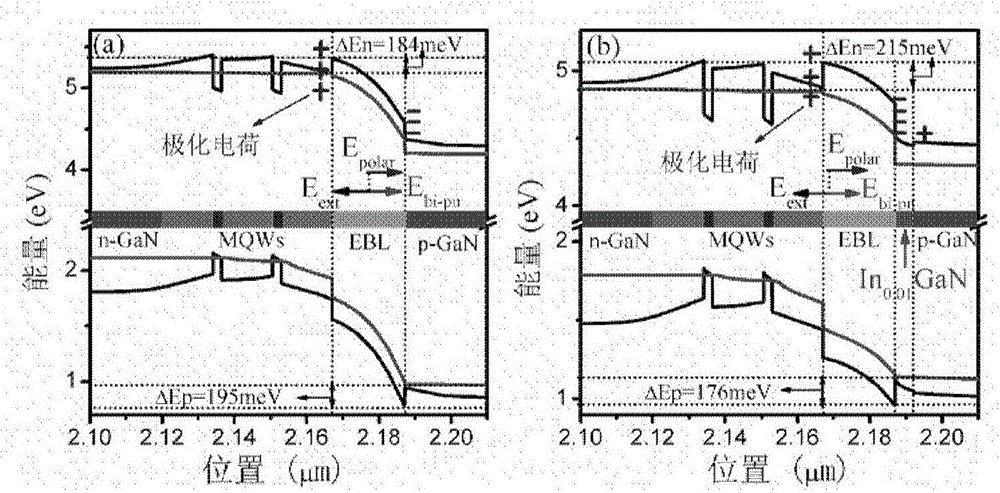

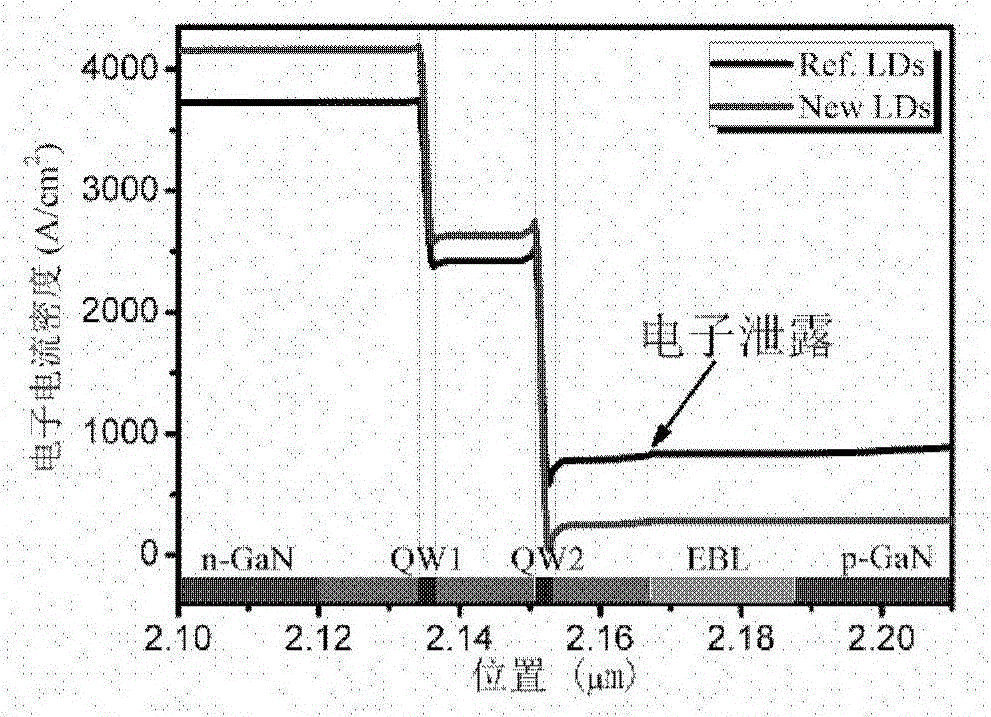

[0024] Due to the introduction of the insertion layer, the above-mentioned laser proposed by the present invention brings two benefits in terms of energy band structure: first, holes are easily injected. The polarization direction of the InGaN insertion layer is from the p region to the n region, causing the valence band of the insertion layer to bend upwards, and the quasi-Fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com