Investment casting technology for copper alloy casting

A technology of investment casting and copper alloy, which is applied in the field of investment casting technology of copper alloy castings, can solve problems such as complex process, and achieve the effects of good toughness, good thermal shock resistance and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Step 1, mold development, the present invention adopts VMCL600 vertical machining center bed type CNC milling machine to set molds, such as some precision parts of auto parts castings.

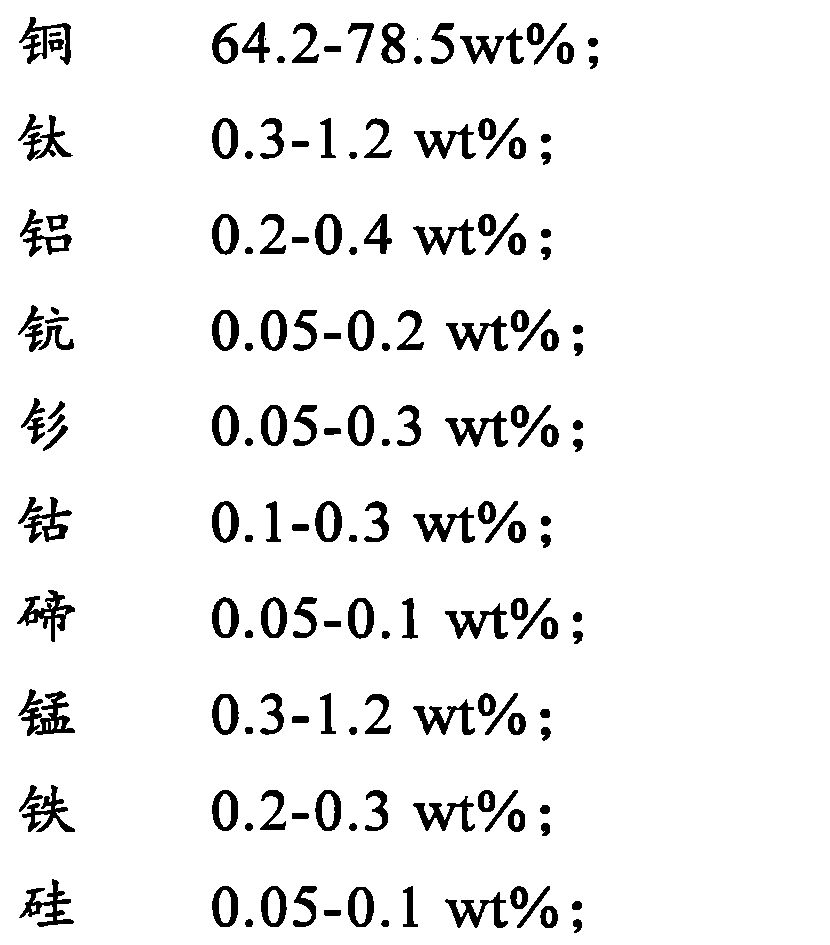

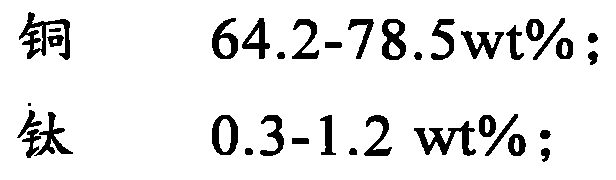

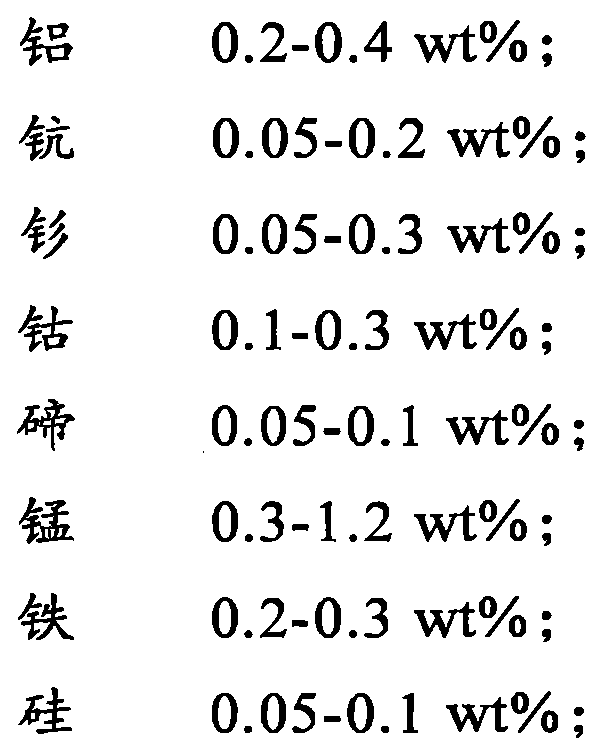

[0058] Step 2, mold making, using the mold to inject wax to prepare a wax model of the product, which is the investment molding process. First configure the mold material, the weight of the mold material is as follows:

[0059]

[0060] When configuring the above substances, an electric hot water bath melting device is used, and the specific operation steps are as follows:

[0061] S1: Weigh the above-mentioned substances in proportion, put the above-mentioned substances into a clean water-bath stainless steel or aluminum crucible, and melt with electricity;

[0062] S2: After the mold material is melted, stir evenly, and the maximum temperature of the mold material should be controlled at 95°C;

[0063] S3: filter the molten molding material with a 120-mesh sieve to remove impurit...

Embodiment 2

[0086] Step 1, mold development, the present invention adopts VMCL600 vertical machining center bed type CNC milling machine to set molds, such as some precision parts of auto parts castings.

[0087] Step 2, mold making, using the mold to inject wax to prepare a wax model of the product, which is the investment molding process. First configure the mold material, the weight of the mold material is as follows:

[0088]

[0089] When configuring the above substances, an electric hot water bath melting device is used, and the specific operation steps are as follows:

[0090] S1: Weigh the above-mentioned substances in proportion, put the above-mentioned substances into a clean water-bath stainless steel or aluminum crucible, and melt with electricity;

[0091] S2: After the mold material is melted, stir evenly, and the maximum temperature of the mold material should be controlled at 95°C;

[0092] S3: filter the molten molding material with a 120-mesh sieve to remove impurit...

Embodiment 3

[0115] Step 1, mold development, the present invention adopts VMCL600 vertical machining center bed type CNC milling machine to set molds, such as some precision parts of auto parts castings.

[0116] Step 2, mold making, using the mold to inject wax to prepare a wax model of the product, which is the investment molding process. First configure the mold material, the weight of the mold material is as follows:

[0117]

[0118] When configuring the above substances, an electric hot water bath melting device is used, and the specific operation steps are as follows:

[0119] S1: Weigh the above-mentioned substances in proportion, put the above-mentioned substances into a clean water-bath stainless steel or aluminum crucible, and melt with electricity;

[0120] S2: After the mold material is melted, stir evenly, and the maximum temperature of the mold material should be controlled at 100°C;

[0121] S3: filter the molten mold material with a 100-mesh sieve to remove impuritie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com