Preparation method of CNT (carbon nanotube) microspheres

A technology of carbon nanotube microspheres and carbon nanotubes, which is applied in the field of preparation of carbon nanotube microspheres, can solve problems such as the dispersion of carbon nanotubes that have not yet been seen, and achieve easy scale-up production, simple equipment and technology, and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

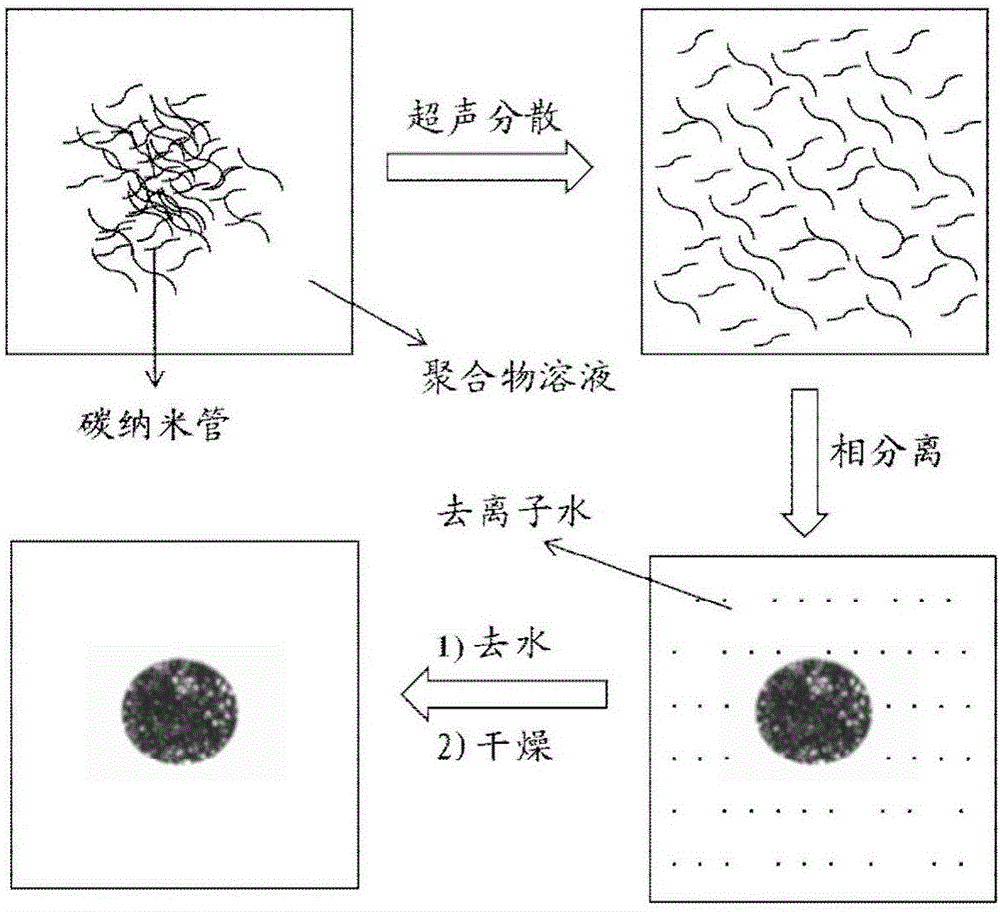

[0030] A preparation method of carbon nanotube microspheres, the specific steps are as follows:

[0031] (1) Preparation of epoxy resin mixed solution: solid glycidyl ether epoxy resin is dissolved in acetone solvent, stirred to make it dissolve evenly, obtain the epoxy resin solution of 0.01g / ml; by weight of epoxy resin, Add 0.01wt% carboxylated carbon nanotubes and 0.01wt% polyethylene glycol octylphenyl ether (tritonX-100) surfactant into the epoxy resin solution, stir for 1min, and ultrasonically disperse for 30min to obtain epoxy resin mixture;

[0032] (2) Preparation of microsphere forming liquid: on the basis of epoxy resin mass, 2wt% polyvinylpyrrolidone was dissolved in deionized water to obtain a microsphere forming liquid of 0.002g / ml, and an electric or magnetic stirrer was used to stir it, Stirring speed is 700rpm;

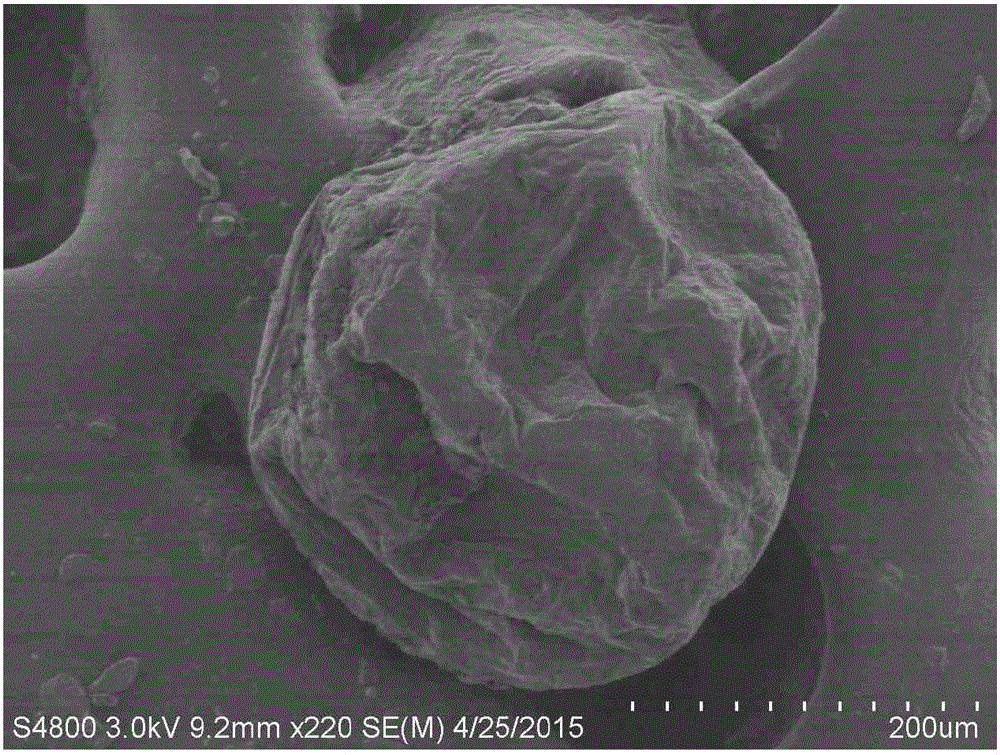

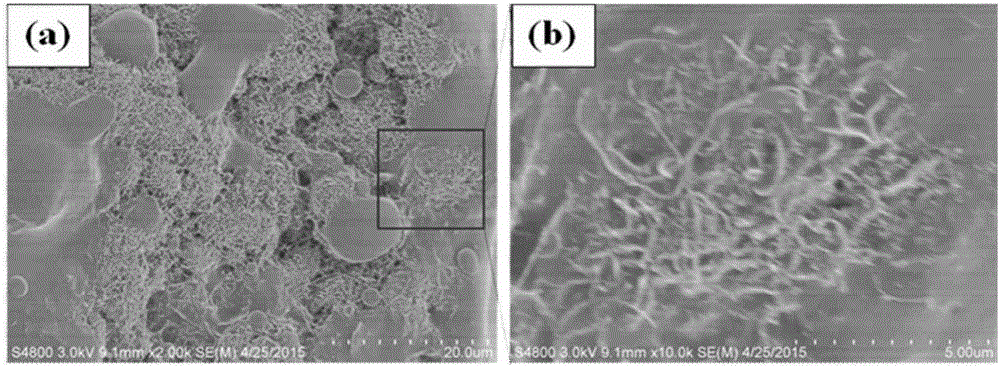

[0033](3) Preparation of carbon nanotube microspheres: the epoxy resin mixed solution of step (1) is ultrasonically dripped into the microsphere ...

Embodiment 2

[0035] A preparation method of carbon nanotube microspheres, which is different from Example 1 in that the resin solution is 0.5g / ml in step (1); the amount of carbon nanotubes is 1wt% (by weight of the resin), and the surface Active agent is 10wt% (by weight of resin), stirred for 2min, and ultrasonically dispersed for 60min; in step (2), 10wt% (by weight of resin) polyvinylpyrrolidone dispersant, and the concentration of microsphere forming liquid is 0.002g / ml , the stirring speed is 3000rpm; in the step (3), the dropping speed is 1.0ml / min, and the stirring speed is 3000rpm, and the stirring is continued for 120min after the solution is all dripped.

Embodiment 3

[0037] (1) Preparation of phenolic resin mixed solution: dissolve solid phenolic resin in acetone solvent, stir to make it dissolve evenly, obtain 0.01g / ml phenolic resin solution; Add nanotubes, 1.0wt% polyoxyethylene sorbitan monolaurate to the phenolic resin solution, stir for 1 min, and ultrasonically disperse for 45 min to obtain a phenolic resin mixed solution;

[0038] (2) Preparation of microsphere forming liquid: 2.0wt% polyvinylpyrrolidone was dissolved in deionized water based on the mass of phenolic resin to obtain a microsphere forming liquid of 0.002g / ml, and an electric or magnetic stirrer was used to stir it, Stirring speed is 900rpm;

[0039] (3) Preparation of carbon nanotube microspheres: the phenolic resin mixed solution of step (1) is ultrasonically dripped into the microsphere forming liquid of step (2), at a rate of 10ml / min, and stirred at 900rpm for 60min with a stirring speed The formed microspheres are filtered out, washed repeatedly with deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com