Domestic sewage purifying agent and preparation method thereof

A technology for domestic sewage and purifying agent, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

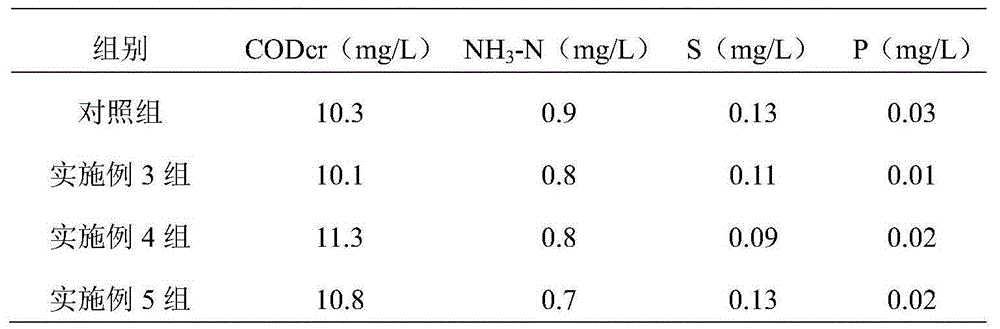

Examples

Embodiment 1

[0019] Party:

[0020] 40 parts of diatomite, 20 parts of silica powder, 15 parts of gypsum powder, 1 part of ferrous chloride, 2 parts of sodium carbonate, 2 parts of aluminum oxide powder, 1 part of Thiobacillus denitrification, 3 parts of Bacillus licheniformis, carboxylic acid 1 part of sodium methylcellulose, 30 parts of polyvinyl alcohol, 800.01 parts of Tween.

[0021] Preparation:

[0022] (1) get Thiobacillus denitrificans and Bacillus licheniformis, make bacterial liquid;

[0023] (2) Mix the above bacterial liquid with sodium carboxymethylcellulose and polyvinyl alcohol, then add Tween 80, stir at 2000r / min for 20 minutes, and dry at 2°C at low temperature to obtain dry powder;

[0024] (3) Take diatomaceous earth, silica powder, gypsum powder, ferrous chloride, aluminum oxide powder and sodium carbonate, grind them into fine powder, and mix them with the above-mentioned dry powder evenly to obtain the product.

Embodiment 2

[0026] Party:

[0027] 40 parts of diatomite, 50 parts of silica powder, 35 parts of gypsum powder, 9 parts of ferrous chloride, 6 parts of sodium carbonate, 8 parts of aluminum oxide powder, 5 parts of Thiobacillus denitrificans, 7 parts of Bacillus licheniformis, 7 parts of sodium methylcellulose, 50 parts of polyvinyl alcohol, 800.05 parts of Tween.

[0028] Preparation:

[0029] (1) get Thiobacillus denitrificans and Bacillus licheniformis, make bacterial liquid;

[0030] (2) Mix the above bacterial liquid with sodium carboxymethyl cellulose and polyvinyl alcohol, then add Tween 80, stir at 4000r / min for 40 minutes, and dry at 4°C at low temperature to obtain dry powder;

[0031] (3) Take diatomaceous earth, silica powder, gypsum powder, ferrous chloride, aluminum oxide powder and sodium carbonate, grind them into fine powder, and mix them with the above-mentioned dry powder evenly to obtain the product.

Embodiment 3

[0033] Party:

[0034] 40 parts of diatomite, 35 parts of silica powder, 25 parts of gypsum powder, 5 parts of ferrous chloride, 4 parts of sodium carbonate, 5 parts of aluminum oxide powder, 3 parts of Thiobacillus denitrifica, 5 parts of Bacillus licheniformis, 4 parts of sodium methylcellulose, 40 parts of polyvinyl alcohol, 800.03 parts of Tween.

[0035] Preparation:

[0036] (1) get Thiobacillus denitrificans and Bacillus licheniformis, make bacterial liquid;

[0037] (2) Mix the above bacterial liquid with sodium carboxymethyl cellulose and polyvinyl alcohol, then add Tween 80, stir at 3000r / min for 30 minutes, and dry at 3°C at low temperature to obtain dry powder;

[0038] (3) Take diatomaceous earth, silica powder, gypsum powder, ferrous chloride, aluminum oxide powder and sodium carbonate, grind them into fine powder, and mix them with the above-mentioned dry powder evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com