BDF board and manufacturing method and application thereof

A glass fiber cotton and K2O technology, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve the problems of increased thermal conductivity, poor heat preservation effect, short service life, etc., and achieve low cost, not easy to absorb moisture, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

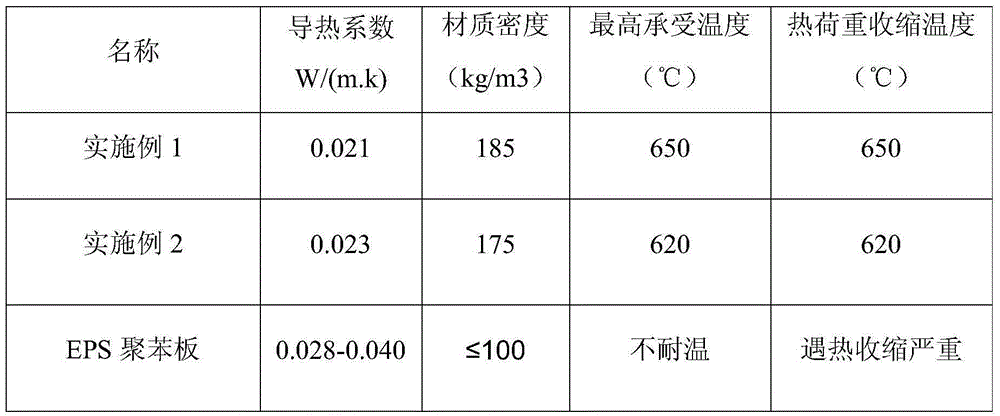

Embodiment 1

[0027] 1) Select silica sand, soda ash, feldspar, dolomite, limestone and Glauber's salt so that the above raw materials meet the following ratio after mixing: SiO 2 : 55 parts, Al 2 o 3 : 25 parts, CaO: 3 parts, MgO: 1.5 parts, K 2 O: 1.5 parts, Na 2 O: 9 parts, BaO: 5 parts;

[0028] 2) Put the raw materials in step 1) into the melting furnace and melt to obtain molten glass, with a melting temperature of 1520°C;

[0029] 3) introducing the molten glass in step 2) into a centrifuge, and when the centrifuge rotates at a high speed, fine streams of glass are thrown out from the side wall of the centrifuge to fibrillate the molten glass;

[0030] 4) In the combustion chamber, use a high-temperature and high-speed flame to further draw the thin glass stream in step 3), and cut it to obtain 0.3 μm glass fibers after reaching a certain length;

[0031] 5) Add glass fiber into the opening machine for opening, and the opening speed is controlled at 100kg / h;

[0032] 6) Then th...

Embodiment 2

[0037] 1) Select silica sand, soda ash, feldspar, dolomite, limestone and Glauber's salt so that the above raw materials meet the following ratio after mixing: SiO 2 : 53 parts, Al 2 o 3 : 27 parts, CaO: 3 parts, MgO: 2 parts, K 2 O: 1 part, Na 2 O: 9 parts, BaO: 5 parts;

[0038] 2) adding the raw materials of step 1) into the melting furnace and melting to obtain molten glass, the melting temperature is 1550°C;

[0039] 3) introducing the molten glass in step 2) into a centrifuge, and when the centrifuge rotates at a high speed, fine streams of glass are thrown out from the side wall of the centrifuge to fibrillate the molten glass;

[0040] 4) In the combustion chamber, use a high-temperature and high-speed flame to further draw and stretch the glass thin stream in step 3), and cut it to obtain 1.5 μm glass fibers after reaching a certain length;

[0041] 5) Add glass fiber into the opening machine for opening, and the opening speed is controlled at 100kg / h;

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com