Gabapentin preparation method

A gabapentin and drop-adding technology, which is applied in the field of gabapentin preparation, can solve the problems of low yield of gabapentin and achieve the effect of increasing yield and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

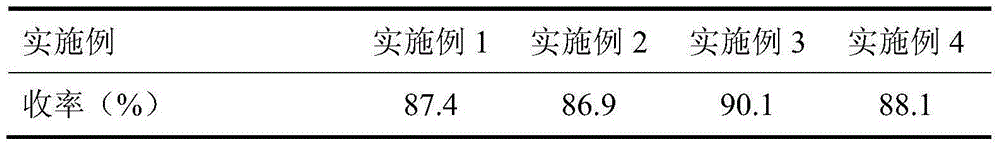

Examples

Embodiment 1

[0020] Put 1mol of cyclohexanone and 2mol of methyl cyanoacetate in a reaction kettle, add 3.0g of ammonium acetate and 10g of methanol as solvent, start stirring, cool to -5°C in an ice-salt bath, slowly add 3mol of ammonia water dropwise to continue the reaction Stir for 3 hours, remove the ice-salt bath, rise to room temperature and let stand for 20 hours, filter and dry to obtain α,α'-dicyano-1,1-cyclohexyldiacetimide ammonium salt; in high temperature liquid water at 160°C Add α,α'-dicyano-1,1-cyclohexyldiacetimide ammonium salt in batches to prevent a large number of bubbles from splashing out of the raw materials during the feeding process, heat to reflux, and obtain after crystallization, suction filtration, and drying Cyclohexyl diacetic acid; add 1.3 mol of urea to 1 mol of cyclohexyl diacetic acid, heat for 2 hours, add 50% ethanol-water solution after cooling to room temperature, heat to reflux, obtain 3,3- Pentamethylene glutarimide; Dissolve 0.12mol of 3,3-pentam...

Embodiment 2

[0022] Put 1mol of cyclohexanone and 3mol of methyl cyanoacetate in a reaction kettle, add 30g of ammonium acetate and 300g of methanol as solvent, start stirring, cool to -5°C in an ice-salt bath, slowly add 3mol of ammonia water dropwise and continue to stir 3h, remove the ice-salt bath, rise to room temperature and let it stand for 20h, filter and dry to prepare α,α'-dicyano-1,1-cyclohexyldiacetimide ammonium salt; dissolve in high temperature liquid water at 190°C Add α,α'-dicyano-1,1-cyclohexyldiacetimide ammonium salt in batches to prevent a large number of bubbles from splashing out the raw materials during the feeding process, heat to reflux, crystallize, suction filter, and dry to obtain cyclo Hexyl diacetic acid; add 1.5 mol of urea to 1 mol of cyclohexane diacetic acid, heat for 4 hours, add 50% ethanol-water solution after cooling to room temperature, heat to reflux, obtain 3,3-penta Methylene glutarimide; 0.12mol of 3,3-pentamethylene glutarimide was dissolved in ...

Embodiment 3

[0024] Put 1mol of cyclohexanone and 2mol of methyl cyanoacetate in a reaction kettle, add 40g of ammonium acetate and 400g of methanol as solvents, start stirring, cool to -8°C in an ice-salt bath, slowly add 3mol of ammonia water dropwise to react and continue stirring 3h, remove the ice-salt bath, rise to room temperature and let it stand for 20h, filter and dry to prepare α,α'-dicyano-1,1-cyclohexyldiacetimide ammonium salt; dissolve in high temperature liquid water at 200°C Add α,α'-dicyano-1,1-cyclohexyldiacetimide ammonium salt in batches to prevent a large number of bubbles from splashing out the raw materials during the feeding process, heat to reflux, crystallize, suction filter, and dry to obtain cyclo Hexyl diacetic acid; add 1.6 mol of urea to 1 mol of cyclohexane diacetic acid, heat for 4 hours, add 50% ethanol-water solution after cooling to room temperature, heat to reflux, obtain 3,3-penta Methylene glutarimide: Dissolve 0.2mol of 3,3-pentamethylene glutarimid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com