PH and temperature dual responsive copolymer and preparation method and application thereof

A copolymer and responsive technology, applied in pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve the problems of high industrialization cost, complex preparation methods, expensive raw materials, etc., and achieve cheap raw materials, easy access to raw materials, The effect of high encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

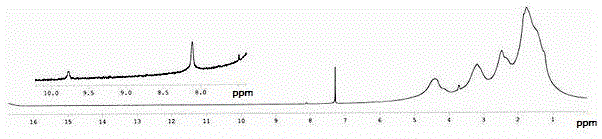

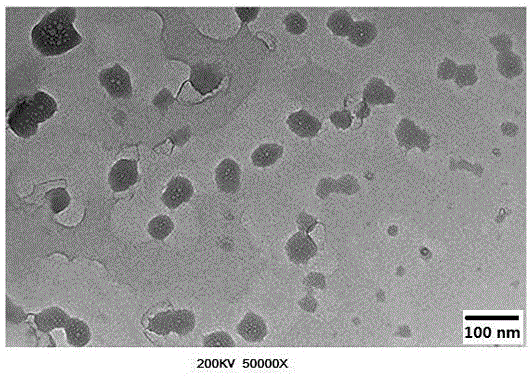

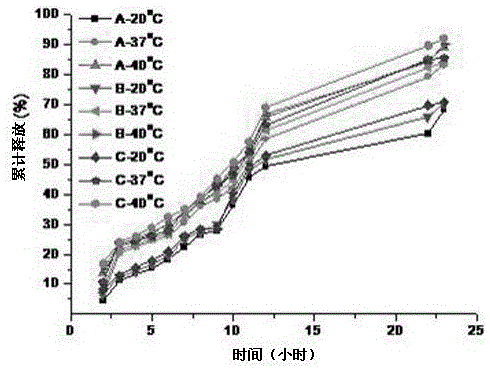

[0036] Add 1.0g N-vinylcaprolactam (NVCL), 3.0mg azobisisobutyronitrile (AIBN) and 5mL dioxane to a dry two-necked flask, evacuate and fill with nitrogen three times, and put the flask into 70°C In the oil bath of 100ml, the dioxane solution of diethyl allyl malonate (prepared by dissolving 0.1g of diethyl allyl malonate in 5mL of dioxane) was added dropwise with stirring. After completion, the polymerization reaction was carried out at 70°C for 24h. Dissolve the polymer with a small amount of THF, pour it into petroleum ether for co-precipitation 3 times, collect the precipitate, evaporate the organic solvent and dissolve it in water, pour the aqueous solution into a dialysis bag with a molecular weight cut-off of 3500, dialyze for 7 days, and vacuum dry to obtain allyl Copolymer of diethylmalonate and N-vinylcaprolactam (PDEAM-co-PNVCL).

[0037] In a dry round-bottomed flask, add 1.0 g of a copolymer of diethyl allylmalonate and N-vinyl caprolactam (PDEAM-co-PNVCL), 35 mL ...

Embodiment 2

[0039] Basically the same as Example 1, the difference is that the consumption of diethyl allyl malonate and N-vinyl caprolactam is different: add 3.0g N-vinyl caprolactam (NVCL), 3.0mg azo to a dry two-necked flask Diisobutyronitrile (AIBN) and 5 mL of dioxane, evacuated and filled with nitrogen for 3 times, put the flask into an oil bath at 70°C, and added the dioxane of diethyl allyl malonate dropwise with stirring The hexacyclic solution (prepared by dissolving 0.5 g of diethyl allyl malonate in 5 mL of dioxane) was dripped and polymerized at 70° C. for 24 h. Dissolve the polymer with a small amount of THF, pour it into petroleum ether for co-precipitation 3 times, collect the precipitate, evaporate the organic solvent and dissolve it in water, pour the aqueous solution into a dialysis bag with a molecular weight cut-off of 3500, dialyze for 7 days, and vacuum dry to obtain allyl Copolymer of diethylmalonate and N-vinylcaprolactam (PDEAM-co-PNVCL).

[0040] In a dry round...

Embodiment 3

[0042] Basically the same as Example 1, the difference is that the consumption of diethyl allyl malonate and N-vinyl caprolactam is different: add 1.0g N-vinyl caprolactam (NVCL), 3.0mg azo to a dry two-necked flask Diisobutyronitrile (AIBN) and 5 mL of dioxane, evacuated and filled with nitrogen for 3 times, put the flask into an oil bath at 70°C, and added the dioxane of diethyl allyl malonate dropwise with stirring The hexacyclic solution (prepared by dissolving 0.3 g of diethyl allyl malonate in 5 mL of dioxane) was dripped and polymerized at 70° C. for 24 h. Dissolve the polymer with a small amount of THF, pour it into petroleum ether for co-precipitation 3 times, collect the precipitate, evaporate the organic solvent and dissolve it in water, pour the aqueous solution into a dialysis bag with a molecular weight cut-off of 3500, dialyze for 7 days, and vacuum dry to obtain allyl Copolymer of diethylmalonate and N-vinylcaprolactam (PDEAM-co-PNVCL).

[0043] In a dry round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com