Wear-resisting modified polyimide composite and preparation method thereof

A polyimide and composite material technology, applied in the field of polymer materials and their preparation, can solve the problem that composite materials cannot achieve friction coefficient, wear rate and mechanical properties, composite material friction coefficient and wear rate are low, PTFE radiation resistance ability Low problems, to achieve the effect of good mechanical strength, low cost, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

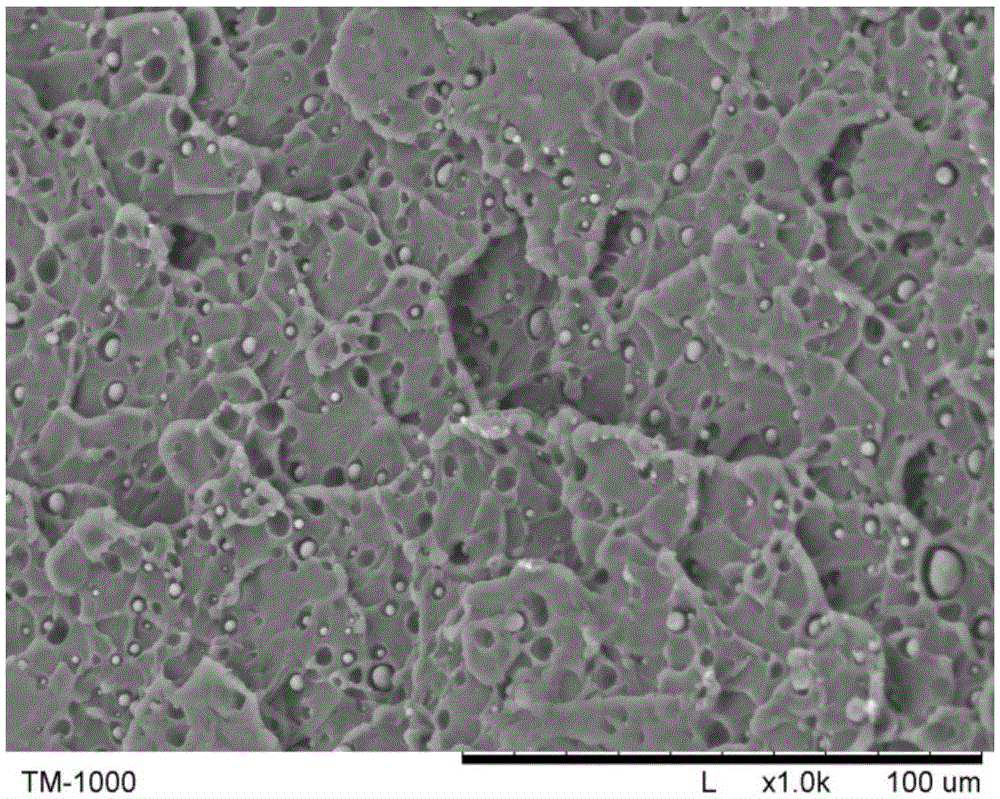

Image

Examples

Embodiment 1

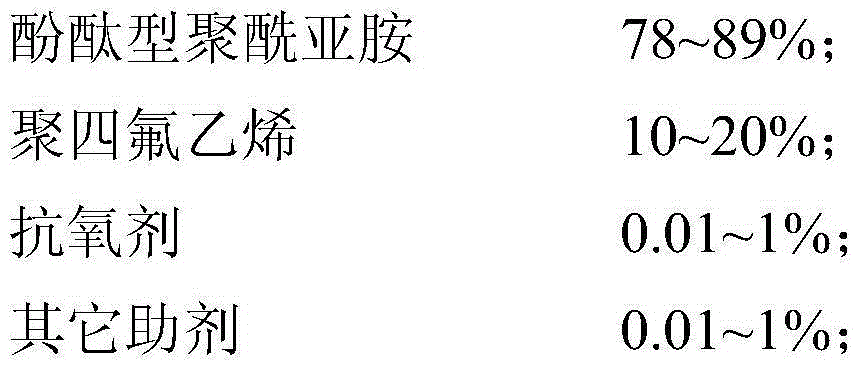

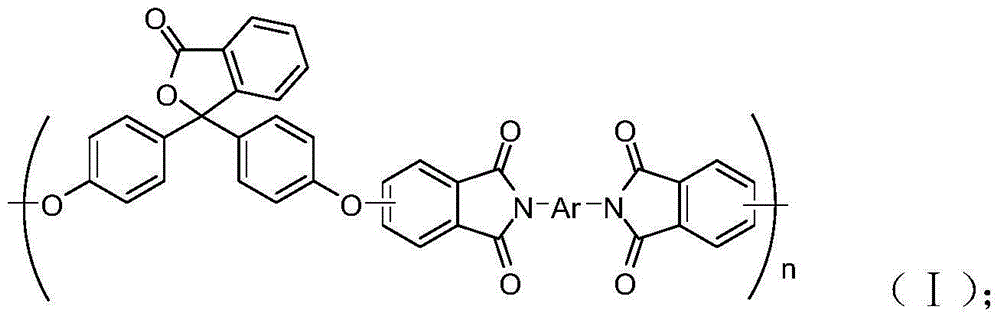

[0053] (1) Phenolphthalein polyimide (Ⅰ-3), polytetrafluoroethylene (trade name is 1600N) powders were dried at 150°C for 3 hours in a forced air drying oven.

[0054] (2) Place the dried phenolphthalein polyimide (I-3) and polytetrafluoroethylene powder, antioxidant 1010, antioxidant 168, lubricant PETS-3 and UV-531 at room temperature at high speed Mix in the mixer for 3 minutes, and mix in 3 times to obtain polyimide / polytetrafluoroethylene composite powder; wherein the mass fraction of phenolphthalein type polyimide (I-3) is 88.4%, and the mass fraction of polytetrafluoroethylene powder The fraction is 10%, the mass fraction of antioxidant 1010 is 0.5%, the mass fraction of antioxidant 168 is 0.5%, the mass fraction of lubricant PETS-3 is 0.3%, and the mass fraction of UV-531 is 0.3%. The uniformly mixed materials were put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to obtain a wear-resistant modified polyimide composite materi...

Embodiment 2

[0058] The preparation process is the same as in Example 1, except that the mass fraction of phenolphthalein polyimide (I-3) is 83.4%, the mass fraction of polytetrafluoroethylene powder is 15%, and the antioxidant 1010 mass fraction is 0.5%. The mass fraction of antioxidant 168 is 0.5%, the mass fraction of lubricant PETS-3 is 0.3%, and the mass fraction of UV-531 is 0.3%, which are mixed in 4 times.

Embodiment 3

[0060] The preparation process is the same as in Example 1, except that the mass fraction of phenolphthalein polyimide (I-3) is 78.4%, the mass fraction of polytetrafluoroethylene powder is 20%, and the antioxidant 1010 mass fraction is 0.5%. The mass fraction of antioxidant 168 is 0.5%, the mass fraction of lubricant PETS-3 is 0.3%, and the mass fraction of UV-531 is 0.3%, and the mixture is divided into 5 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com