A kind of polyionic liquid modified graphene/thermosetting resin composite material and preparation method thereof

A technology of resin composite material and polyionic liquid, which is applied in the field of graphene/thermosetting resin composite material and its preparation, can solve the problem that the improvement range needs to be improved, and achieve the effects of improving modification efficiency, good dispersibility and excellent electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

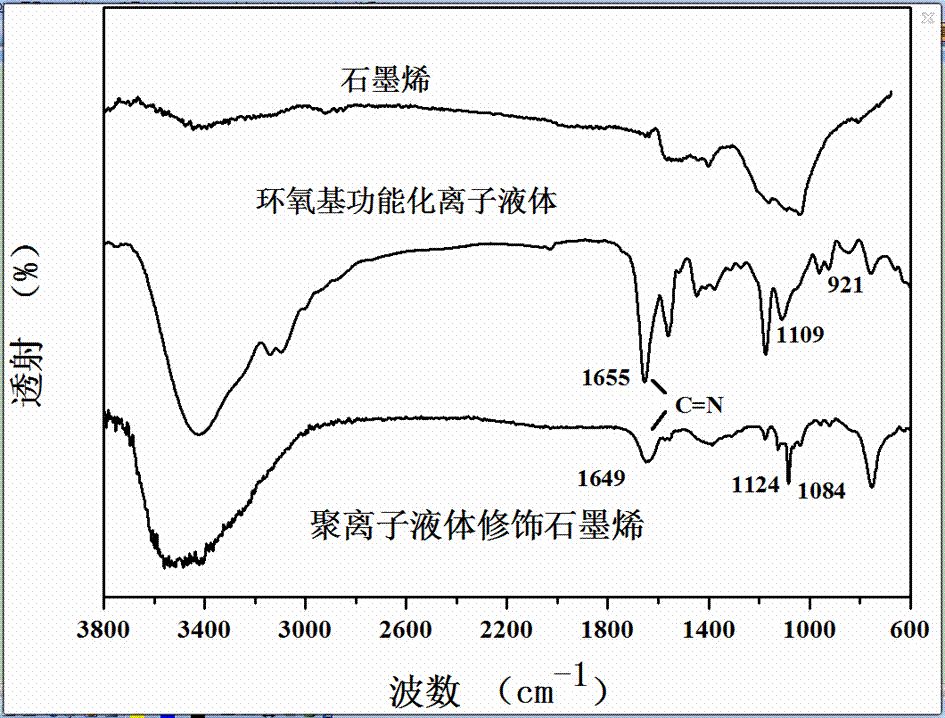

[0038] The present embodiment provides a graphene / bisphenol A type cyanate resin composite material modified by polyionic liquid, and the specific steps of its preparation method are as follows:

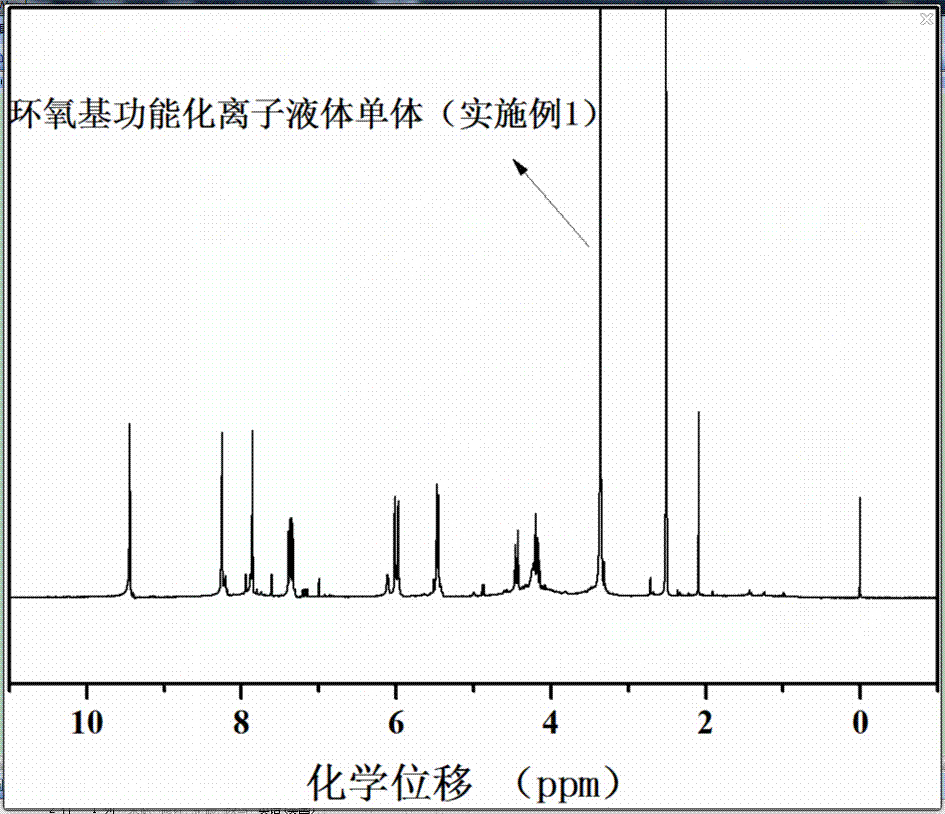

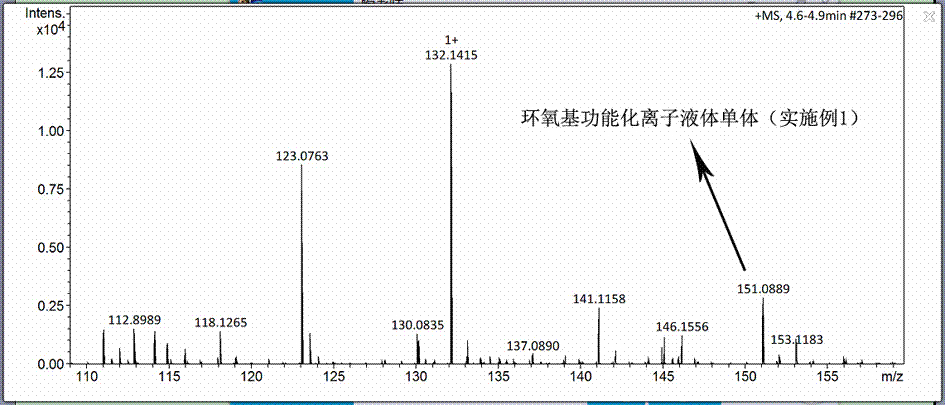

[0039] (1) Preparation of epoxy-functionalized ionic liquid monomer

[0040] in N 2 Under protection, mix 1g of N-vinylimidazole and 0.98g of epichlorohydrin, raise the temperature, and reflux for 24 hours; after the reaction, wash repeatedly with ether and dry in vacuum at 25°C for 4 hours to obtain ionic liquid monomer A.

[0041] 1g of prepared ionic liquid monomer A was dissolved in 10mL of methanol to obtain solution B; 0.59g of NaBF 4 The crystals were slowly added to solution B, stirred and reacted at 25°C for 24 hours; the solvent methanol was distilled off under reduced pressure, dissolved in acetone, and the insoluble salt was removed by filtration. Acetone was distilled off under reduced pressure, and vacuum-dried at 40° C. for 4 hours to obtain an epoxy-functionalized i...

Embodiment 2

[0064] The 0.88g polyionic liquid-modified graphene hybrid material prepared in Example 1 was melt-mixed with 100g 2,2-bis(4-cyanophenyl)propane (bisphenol A cyanate) at 160°C, Then ultrasonically disperse and stir at 80° C. for 30 min to obtain a homogeneous mixture. Pour the mixture into the mold, vacuum defoam at 160°C for 30 minutes, and perform curing and post-treatment according to the processes of 160°C / 2h+180°C / 2h+200°C / 2h+220°C / 2h and 240°C / 4h , That is to obtain a polyionic liquid-modified graphene / bisphenol A cyanate resin composite material, wherein the content of graphene is 0.8wt%. The electrical conductivity of the composite material prepared in this embodiment at 1 Hz is shown in the appendix Figure 14 .

Embodiment 3

[0066] The 0.66g polyionic liquid-modified graphene hybrid material prepared in Example 1 was melt-mixed with 100g 2,2-bis(4-cyanophenyl)propane (bisphenol A cyanate) at 160°C, Then ultrasonically disperse and stir at 80° C. for 30 min to obtain a homogeneous mixture. Pour the mixture into the mold, vacuum defoam at 160°C for 30 minutes, and perform curing and post-treatment according to the processes of 160°C / 2h+180°C / 2h+200°C / 2h+220°C / 2h and 240°C / 4h , That is to obtain a polyionic liquid modified graphene / bisphenol A type cyanate resin composite material, wherein the content of graphene is 0.6wt%. The electrical conductivity of the composite material prepared in this embodiment at 1 Hz is shown in the appendix Figure 14 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com