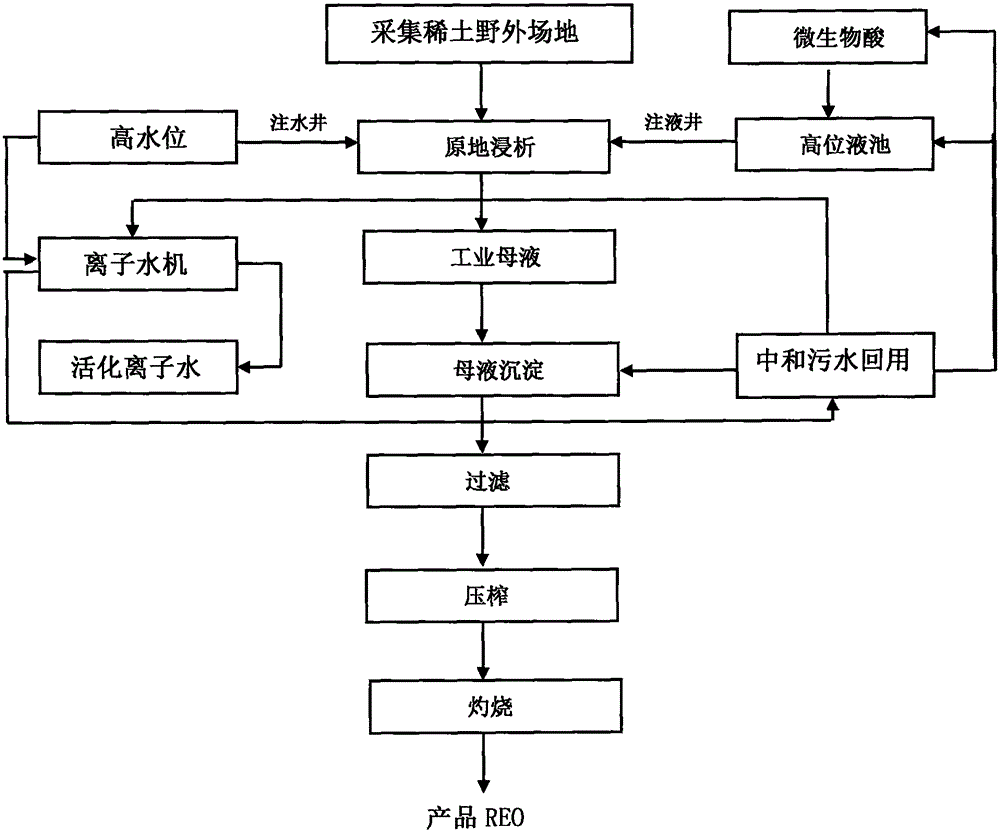

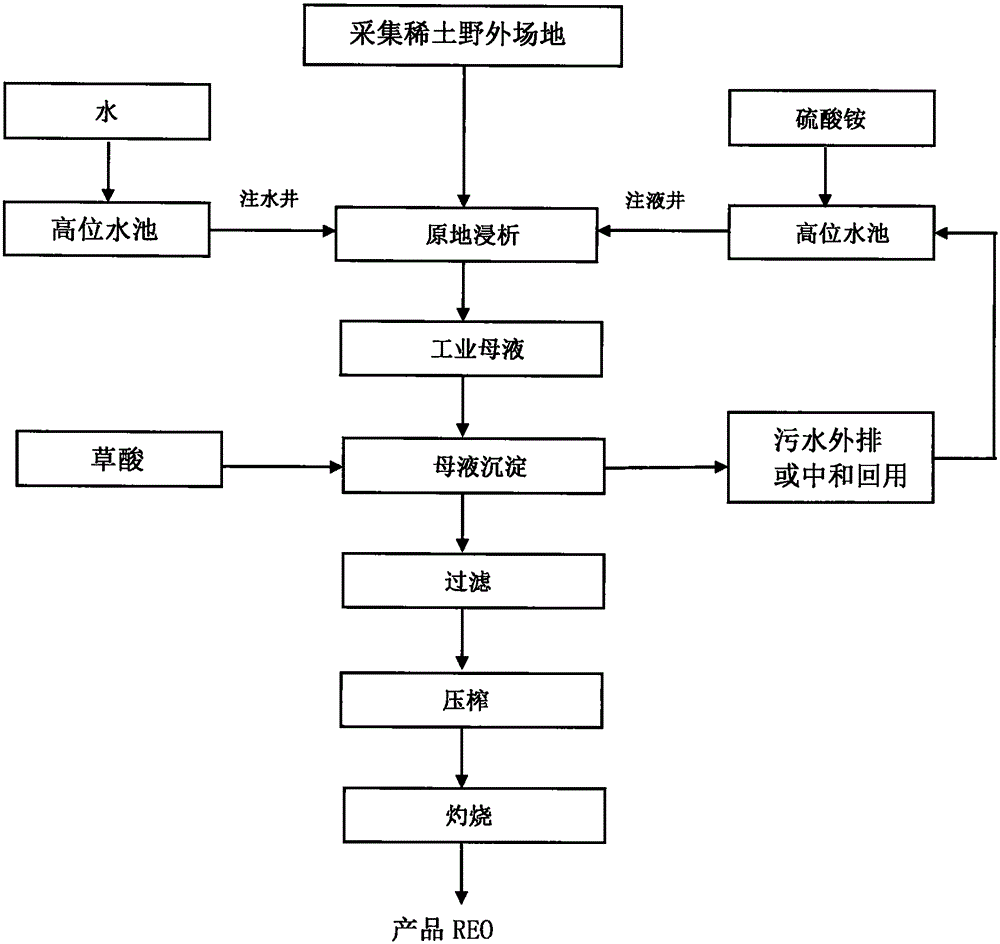

Technology for improving ion type rare earth in-situ leaching method by activated ion water and microorganism acid

An ion-type rare earth, in-situ leaching technology, applied in the direction of improving process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

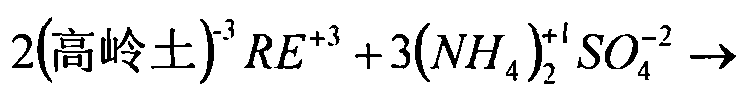

Method used

Image

Examples

Embodiment 1

[0021] Example [1]: Example of culturing microbial acid

[0022] A kind of ore leaching agent for ion rare earth leaching, its typical culture medium formula is:

[0023]

[0024]

[0025] Culture process and conditions, parameters

[0026] current date (time)

[0027] The above is the leaching agent obtained by using 1% self-prepared lactic acid bacteria stock solution after 3 days of cultivation (72 hours) at the beginning of the research and development stage, and the pH value changed from the initial 6.4 to 3.1. It can be used as the ore leaching liquid for in-situ ion rare earth mining. This formula can be further optimized according to the specific conditions of the soil around the ion rare earth mine. Select the optimum culture temperature and shorten the growth cycle (required less than 18 hours), so as to meet the needs of large-scale industrial production. The fungi in the lactic acid-like seed stock solution of the present invention are anaerobic ...

Embodiment 2

[0028] Embodiment [2] The improved process of activated ion water instead of oxalic acid as precipitant

[0029] 1. Overview: Use acid and alkali mixed ion water and acid ion water with a salt content of 1‰ and 5‰ respectively as the stock solution, and then add oxalic acid as an auxiliary agent to form a 19# rare earth acid precipitant.

[0030] 2. To prepare acidic ionized water and acid-base mixed ionized water with a salt content of 1‰, the specific operation data are as follows:

[0031] A, Q total = 12.15L / Min = 729L / H

[0032] (1), Q acid=10.4L / Min=621L / H, acidic ion water PH=2.9

[0033] (2), Q base=1.7L / Min=102L / H, alkaline ionized water PH=11.4

[0034] (3), Q acid+Q base=Q acid-base mixed ion water, its PH=8.8

[0035] B. (1) PH2.9 acidic ionized water / liter + 4.5 g / liter oxalic acid = pH1.4 acidic ionized water (note 19#-1)

[0036] (2)PH8.8 acid-base mixed ion water / liter+4.5g / liter oxalic acid=PH1.5 acidic ion water (note 19#-2)

[0037] 3. To prepare acidic...

Embodiment 3

[0053] Example [3]: An implementation example of a new in-situ extraction process where activated ionized water replaces pure oxalic acid and biological acid replaces thiamine. Using the formula and process of the present invention, we conducted an extraction comparison experiment on an ion-type rare earth ore in a certain place in northern Guangdong. The results of this experiment will be published later. Among them, there are several abbreviations that need to be explained in advance: HOH means activation. HOH water is the activated ionized water generated by adding additives to electrolyzed water. HOH acid: Refers to active biological acid. The number definitions of the two extractants are given in the report:

[0054] HOH-XT-2014-NOC-18, referred to as 18# extractant, essentially uses activated acidic ionized water instead of oxalic acid as the mother liquor precipitant.

[0055] HOH-XT-2014-BIO-019, referred to as 19# extraction agent, essentially refers to the use of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com