Detection method for odor substances in water environment

A detection method and water environment technology, applied in the field of analysis and detection, can solve the problems of affecting the extraction effect, decreasing the detection accuracy, easily generating foam, etc., and achieving the effects of simple and easy operation, reduced damage and high recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

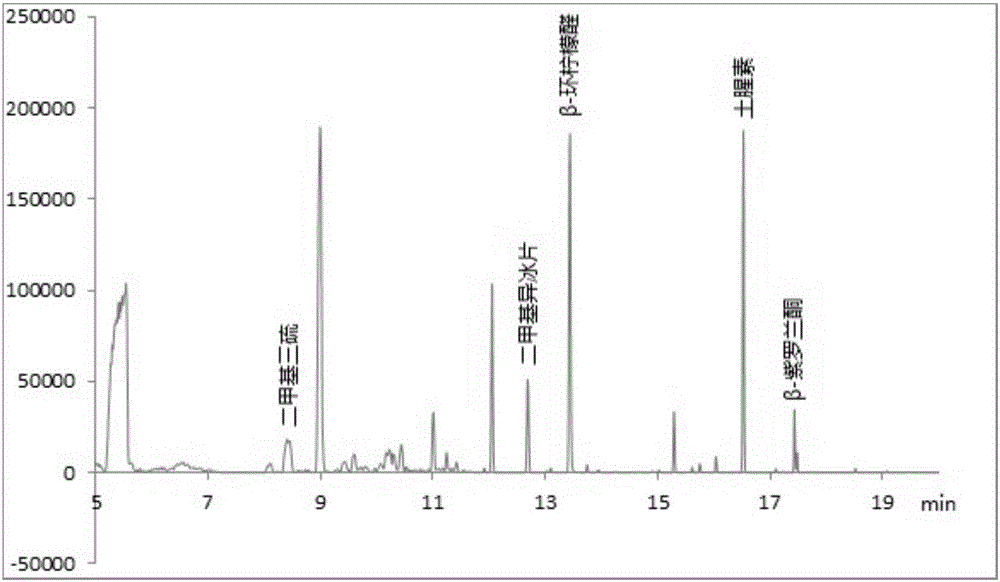

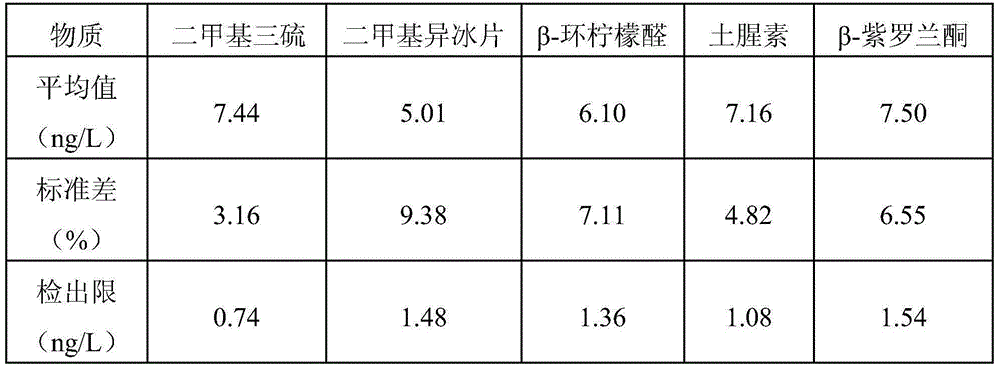

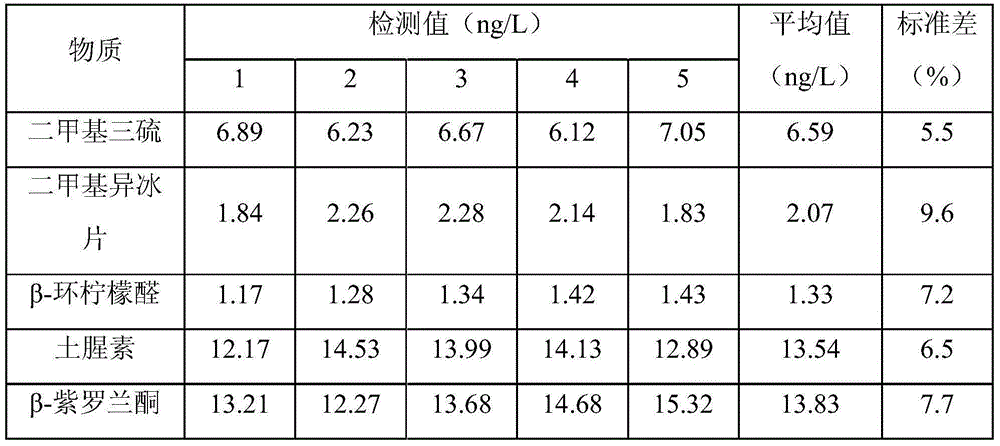

Embodiment 1

[0050] A method for detecting odorous substances in a water environment, comprising the steps of: diluting a mixed standard stock solution to obtain mixed mixtures with concentrations of 5ng / L, 10ng / L, 20ng / L, 40ng / L, 100ng / L, and 200ng / L, respectively. Standard solution, the mixed standard solution of each concentration is placed in the solid-phase microextraction sample vial with PTFE cover respectively, add the NaCl that the addition amount is 30% of the mixed standard solution quality, put into PTFE cylindrical magnetic stirring bar, and control The temperature of the solid-phase microextraction sample vial is 65°C, and the magnetic stirring speed is 1500r / min. Then, the extraction fiber aged at 270°C for 1 hour: 85 μm CAR / PDMS is placed in the solid-phase microextraction vial for extraction for 30 minutes. After the extraction, Transfer the extracted fiber to a gas chromatography-mass spectrometer for detection, and use the external standard peak area method for quantitati...

Embodiment 2

[0071] A method for detecting odorous substances in a water environment, comprising the following steps:

[0072] (1) Standard curve preparation: Dilute the mixed standard stock solution to obtain mixed standard solutions with concentrations of 5ng / L, 10ng / L, 20ng / L, 40ng / L, 100ng / L, and 200ng / L, and mix the mixed standard solutions of each concentration The standard solution is placed in the solid-phase microextraction sample bottle with PTFE cover respectively, and the addition amount is the NaCl of 10% of the quality of the mixed standard solution, put into the PTFE cylindrical magnetic stirrer, and control the temperature of the solid-phase microextraction sample bottle to be 45°C, the magnetic stirring speed is 1000r / min, and then the extraction fiber aged at 270°C for 1h - 100μm PDMS is placed in the solid phase microextraction vial for extraction for 10min. After the extraction is completed, the extracted extraction fiber is transferred to the gas phase Detect in the ch...

Embodiment 3

[0075] (1) Standard curve preparation: Dilute the mixed standard stock solution to obtain mixed standard solutions with concentrations of 5ng / L, 10ng / L, 20ng / L, 40ng / L, 100ng / L, and 200ng / L, and mix the mixed standard solutions of each concentration The standard solution is placed in the solid-phase microextraction sample bottle with PTFE cover respectively, and the NaCl that the addition amount is 20% of the quality of the mixed standard solution is added, and the PTFE cylindrical magnetic stirrer is put into it, and the temperature of the solid-phase microextraction sample bottle is controlled to 75°C, the magnetic stirring speed is 100r / min, and then the extraction fiber aged at 270°C for 1h - 30 / 50μmCAR / DVB / PDMS is placed in a solid-phase microextraction vial for 40min extraction. After the extraction is completed, the extracted The extracted fibers were transferred to a gas chromatography-mass spectrometer for detection, and quantitatively determined by the external standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com