Cogeneration method for producing monopotassium phosphate and potassium diformate

A technology of potassium dihydrogen phosphate and potassium diformate, applied in chemical instruments and methods, preparation of phosphorus compounds and carboxylates, etc., can solve the pressure of low price, not to mention popularization of potassium diformate, loss of environmental protection of formic acid, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Raw material and output balance sheet

[0060]

[0061] as attached figure 1 Shown: 1#~4# after the tail gas of calcium carbide furnace with installed capacity of 25,500 KVA is purified by dry and wet method: the gas carbon monoxide content is more than 75%, oxygen is less than 0.5%, hydrogen is about 15%, and dust is less than 10mg / Nm 3 , the gas flow rate is 2000~2500Nm 3 / h enters the gas cabinet for storage, in which the dry and wet purification water washing circulation pool 39# supplementary water comes from the process wastewater 48# at the rear, and the dust and coal slurry is fully mixed 38# and sent to the coal-fired boiler 43# as a desulfurizer.

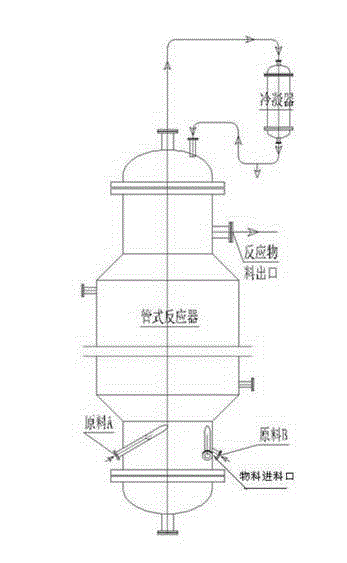

[0062] Potassium hydroxide solution by-product of selective ionic membrane chlor-alkali: content 32% potassium hydroxide, flow rate 10-15Nm 3 / h, enter the preheater 9# (tube preheater) through 8# pressurization to less than 2.4MPa, use the high-temperature gas phase gas after the synthesis of pressure release an...

Embodiment 2

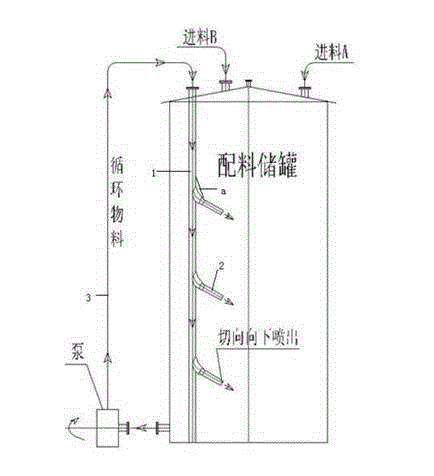

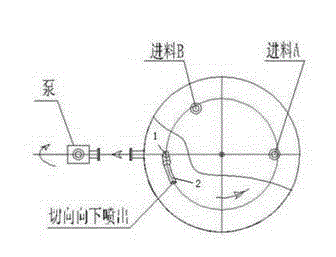

[0068] In the evaporation process of the above-mentioned Example 1 "alkaline potassium formate synthetic liquid", 1000g of molten potassium formate with a content of 90% was taken, and put into a 3000mml stainless steel storage tank 14# with a stirring, heat preservation and electric heating jacket, and an inert gas or electric heating was added. Make the tank have a pressure of 0.1MPa, and connect one of the four tangential inlets at the lower part of the pipeline reactor 16# through the lower outlet through the valve pipeline. The outlet at the 1-meter elevation is equipped with electric heating and insulation jacket, and the upper part is 0.5 meters with a jacket for water heat exchange. The other inlet corresponding to the lower part of the pipeline reactor is connected to the lower part of the 15# 3000ml stainless steel storage tank. The outlet is connected by a valve pipe. The 15# storage tank is filled with 1235g of phosphoric acid with a content of 85%. Add inert gas or...

Embodiment 3

[0073] Get content 85% molten potassium formate 1000g in above-mentioned embodiment 1 " basic potassium formate synthesis liquid " evaporation process, get 1200 content 85% phosphoric acid and adopt the same system and method of embodiment 2, get finished product potassium dihydrogen phosphate 1380g content 98 %, and separated mother liquor distillation, gas phase condensation to obtain 710g of formic acid with a content of 61%, 200g of raffinate after distillation is ready for next use, the yield of potassium dihydrogen phosphate is 96.2%, and the yield of formic acid is 93.0%.

[0074] In above-mentioned embodiment 1 " alkaline potassium formate synthesis liquid " evaporation process, take content 85% molten potassium formate 900g, the formic acid 710g that above-mentioned condensation obtains content 61% adopts the same system and method of embodiment 2, obtains finished product potassium diformate The content of 980g is 98%. Most of the separated mother liquor is returned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com