A kind of preparation method of oligomeric isomaltitol

A technology of isomalt oligosaccharide and maltitol, which is applied in the field of preparation of isomalt oligosaccharide, can solve the problems of low recovery rate, high energy consumption and high recovery rate, and achieves low stirring resistance, good separation effect and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

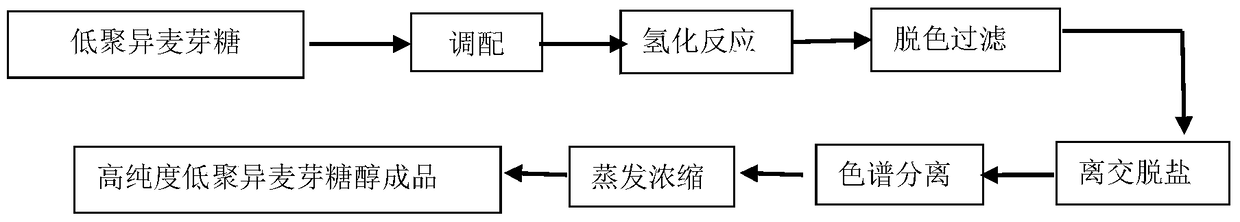

Method used

Image

Examples

Embodiment 1

[0018] 1) The 50-type isomaltooligosaccharide solution (the dry matter concentration is 35-55%, and the proportion of IMO in the total sugar is 45-55%) is slurried with sodium hydroxide, and the pH is adjusted to 7.0;

[0019] 2) Hydrogenation reaction, the temperature is controlled at 90°C, and then slowly raised to 110°C, the hydrogen pressure is 7MPa; the catalyst is skeleton nickel, and the addition amount is 6% of the dry matter; the stirring speed is 160r / min.

[0020] 3) decolorization, separation. Activated carbon decolorization, the amount of carbon added is 5%% of the dry matter, the decolorization temperature is 70°C, and the decolorization time is 60min; when the decolorization is performed, the decolorized feed solution is passed through a cation-anion-cation exchange column to remove ions and impurities.

[0021] 4) Chromatographic separation, using a strong acid resin, the feed concentration is 40%, the flow rate is 4L / h, and the feed liquid temperature is 50°C....

Embodiment 2

[0024] 1) The 50-type isomaltooligosaccharide solution (the dry matter concentration is 35-55%, and the proportion of IMO in the total sugar is 45-55%) is slurried with sodium hydroxide, and the pH is adjusted to 7.5;

[0025] 2) Hydrogenation reaction, the temperature is controlled at 100°C, and then slowly raised to 125°C, the hydrogen pressure is 8.5MPa; the catalyst is skeleton nickel, and the addition amount is 8% of the dry matter; the stirring speed is 190r / min r / min.

[0026] 3) decolorization, separation. For activated carbon decolorization, the amount of carbon added is 8% of the dry matter, the decolorization temperature is 80°C, and the decolorization time is 45 minutes; when decolorizing, the decolorized feed liquid is passed through a cation-anion-cation exchange column to remove ions and impurities.

[0027] 4) Chromatographic separation, using a strong acid resin, the feed concentration is 50%, the flow rate is 3L / h, and the feed liquid temperature is 60°C.

...

Embodiment 3

[0030] 1) The 50-type isomaltooligosaccharide solution (the dry matter concentration is 35-55%, and the proportion of IMO in the total sugar is 45-55%) is slurried with sodium hydroxide, and the pH is adjusted to 7.9;

[0031] 2) For hydrogenation reaction, the temperature is controlled at 110°C, then slowly raised to 140°C, and the hydrogen pressure is 10MPa; the catalyst is skeleton nickel, and the addition amount is 11% of the dry matter; the stirring speed is 220r / min.

[0032] 3) decolorization, separation. Activated carbon decolorization, the amount of carbon added is 10% of the dry matter, the decolorization temperature is 90°C, and the decolorization time is 30 minutes; when decolorizing, the decolorized feed solution is passed through a cation-anion-cation exchange column to remove ions and impurities.

[0033] 4) Chromatographic separation, using a strong acid resin, the feed concentration is 60%, the flow rate is 2L / h, and the feed liquid temperature is 70°C.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com