Metal cutting fluid for machine tool

A metal cutting fluid and machine tool technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as poor stability, poor resistance to bacteria and mildew, and achieve good stability, good hydrophilicity, and reduced surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

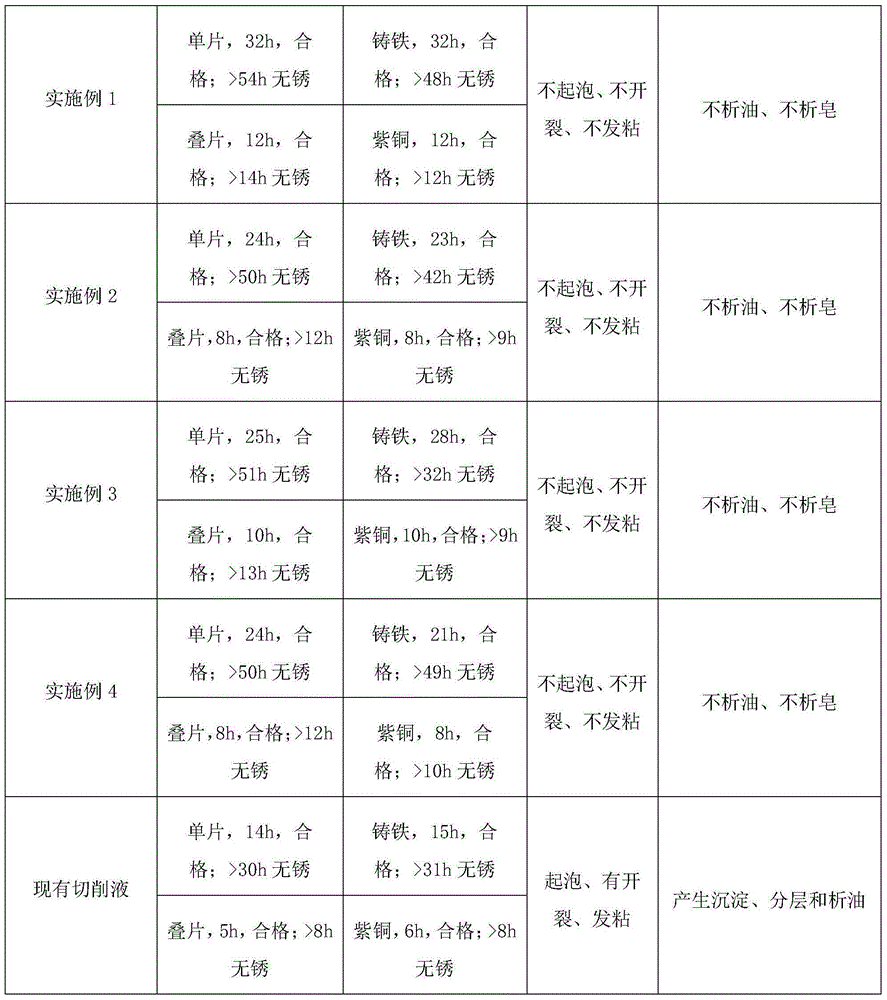

Examples

Embodiment 1

[0012] A metal cutting fluid for machine tools, consisting of the following raw materials in parts by mass: 8 parts of lanthanum sulfate, 2 parts of tricresyl phosphate, 5 parts of tetrabutyl titanate, 0.7 parts of polyglycerol fatty acid, 0.8 parts of potassium fluorotitanate, 8 parts of allyl polyethylene glycol, 0.8 parts of barium stearate, 6 parts of additives, 75 parts of deionized water, 8 parts of boric acid, 10 parts of sodium petroleum sulfonate, 2 parts of amino alcohol;

[0013] The auxiliary agent is made of the following raw materials in parts by mass: 6 parts of alkenyl succinate, 4 parts of lanolin, 10 parts of polyethylene glycol, 2 parts of nano silicon dioxide, 120 parts of deionized water, high Wear-resistant carbon black 5 parts, silicone oil 2 parts.

[0014] The preparation method of the metal cutting fluid comprises the following steps:

[0015] 1) Preparation of additives: Mix polyethylene glycol and lanolin into the reaction kettle, heat and melt, ad...

Embodiment 2

[0020] A metal cutting fluid for machine tools, consisting of the following raw materials in parts by mass: 7 parts of lanthanum sulfate, 2 parts of tricresyl phosphate, 5 parts of tetrabutyl titanate, 0.5 parts of polyglycerol fatty acid, 0.6 parts of potassium fluorotitanate, 7 parts of allyl polyethylene glycol, 0.8 parts of barium stearate, 4 parts of additives, 70 parts of deionized water, 6 parts of boric acid, 8 parts of sodium petroleum sulfonate, 1 part of amino alcohol;

[0021] The auxiliary agent is made of the following raw materials in parts by mass: 6 parts of alkenyl succinate, 4 parts of lanolin, 10 parts of polyethylene glycol, 1 part of nano silicon dioxide, 120 parts of deionized water, high Wear-resistant carbon black 5 parts, silicone oil 2 parts.

[0022] Preparation method is the same as embodiment 1

Embodiment 3

[0024] A metal cutting fluid for machine tools, consisting of the following raw materials in parts by mass: 10 parts of lanthanum sulfate, 3 parts of tricresyl phosphate, 6 parts of tetrabutyl titanate, 0.8 parts of polyglycerol fatty acid, 1 part of potassium fluorotitanate, 9 parts of allyl polyethylene glycol, 1 part of barium stearate, 6 parts of additives, 80 parts of deionized water, 8 parts of boric acid, 12 parts of sodium petroleum sulfonate, 2 parts of amino alcohol;

[0025] The auxiliary agent is made of the following raw materials in parts by mass: 7 parts of alkenyl succinate, 5 parts of lanolin, 14 parts of polyethylene glycol, 2 parts of nano silicon dioxide, 150 parts of deionized water, high 6 parts of wear-resistant carbon black, 3 parts of silicone oil.

[0026] Preparation method is the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com