Castable aluminum alloy material for cylinder cover and preparation method thereof

A technology of aluminum alloy material and waste aluminum intermediate alloy, applied in the field of aluminum alloy, can solve the problems of aluminum smelting consuming large energy, exacerbating energy crisis, bauxite depletion, etc., and improving castability, formability and good processing performance. , the effect of improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

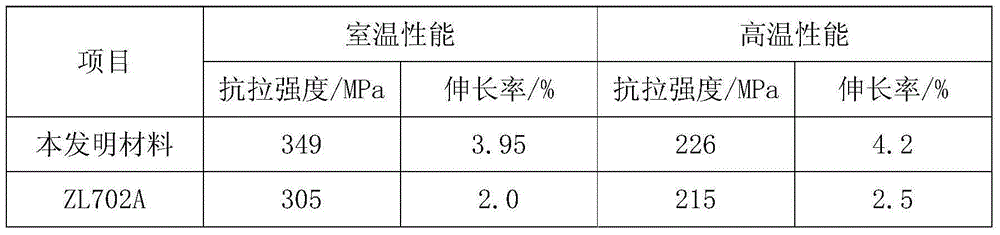

Examples

Embodiment Construction

[0015] The present invention will be described in detail below through specific examples.

[0016] A castable aluminum alloy material for cylinder head, which is composed of the following components in mass percentage: 6.5% silicon, 0.55% zinc, 0.4% nickel, 0.2% vanadium, 0.22% magnesium, 0.2% iron, 0.1% tin, 45% waste aluminum master alloy powder, and The amount is aluminum;

[0017] The waste aluminum master alloy powder is made of the following raw materials in parts by weight (kg): 60 waste aluminum scraps, 15 manganese, 10 copper, 6 chromium, 7 zirconium, 2 graphite powders, 1.5 sodium chloride, and 1 cryolite powder; The method is as follows: (1) Use a permanent magnet to suck out the iron products in the waste aluminum chips, then use an iron mesh sieve to remove the dust and sand, then use a detergent to remove the oil stains on the surface, and finally put it in an oven to dry the water and wait for it to dry. (2) Put the surface-treated waste aluminum into the cruci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com