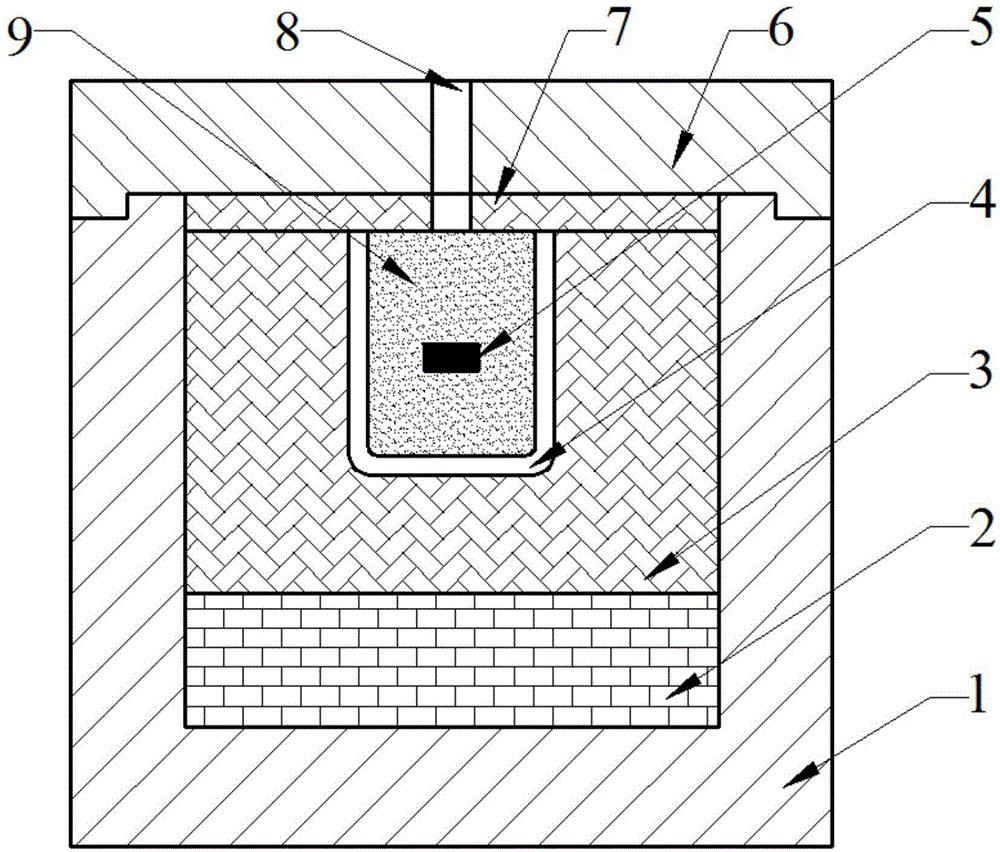

Thermal insulation and auxiliary heating device for microwave sintering of ceramic cutter material

A technology of auxiliary heating and ceramic knives, which is applied in lighting and heating equipment, furnaces, charging support, etc., can solve the problems of affecting the heat preservation effect of the sintering process, affecting the sintering performance of materials, and not providing heating heat sources, so as to avoid heat loss, Good interchangeability, anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

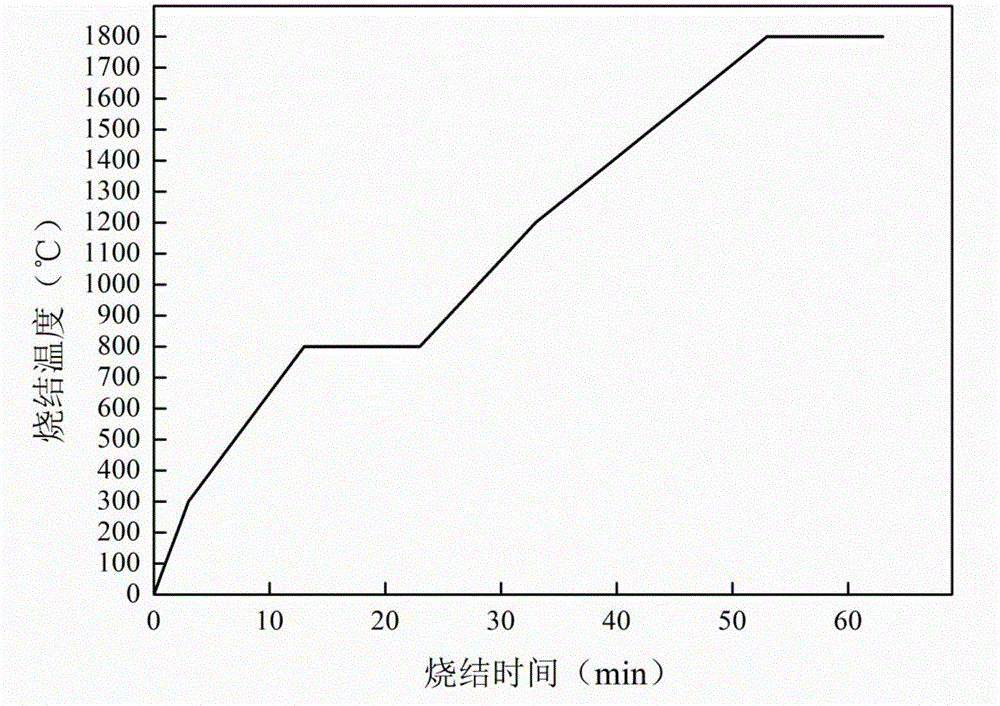

Embodiment 1

[0030] Sintering of alumina-based ceramic materials. The sample to be sintered is placed inside the crucible and the crucible is completely filled with micron-sized silicon carbide, graphite and activated carbon mixed powder, and the alumina fiber cotton cover and mullite cover are sequentially covered. Put the device into the cavity of the microwave oven, adjust the relative position of the infrared in the thermometer and the green body, and ensure that the infrared can enter the auxiliary heating area through the probe hole, then close the oven door, and turn on the microwave power switch to figure 2 The schematic diagram of the sintering process curve shown in the figure shows that the sintering is completed. The temperature of the sintered sample reaches 1800°C in about 50 minutes, and then it is kept for 10 minutes. The whole sintering process lasts about 60 minutes. After the sintering is completed, it is cooled to room temperature with the furnace. The relative density...

Embodiment 2

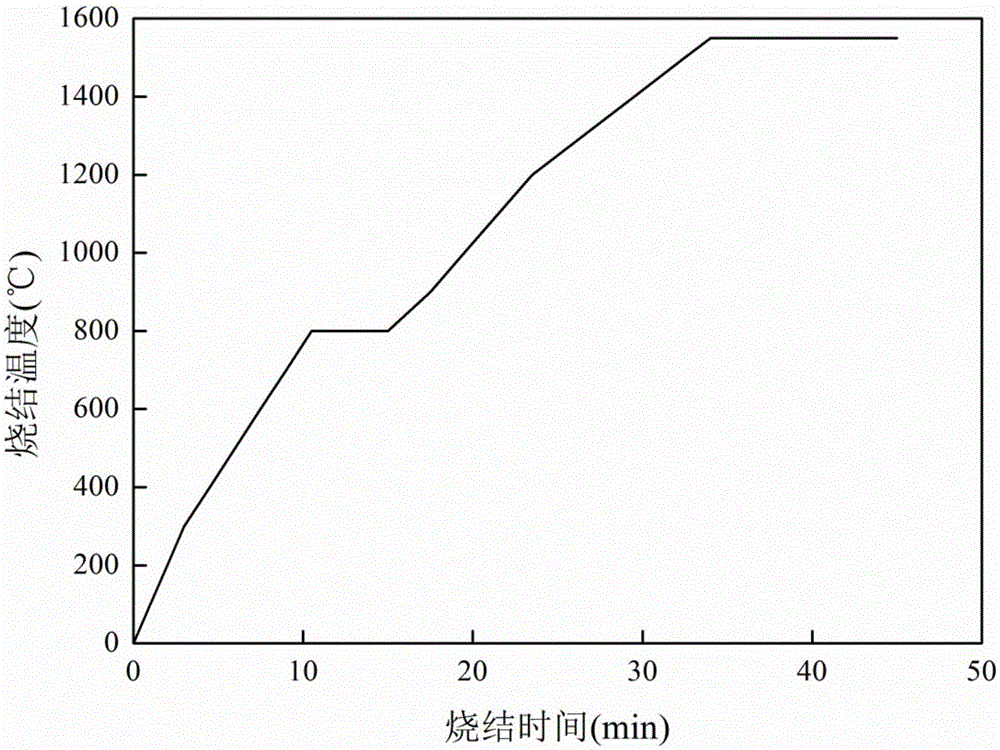

[0032] Sintering of titanium carbonitride-based ceramic tool materials. The sample to be sintered is placed inside the crucible and the crucible is completely filled with micron-sized silicon carbide, graphite and activated carbon mixed powder, and the alumina fiber cotton cover and mullite cover are sequentially covered. Put the device into the cavity of the microwave oven, adjust the relative position of the infrared in the thermometer and the green body, and ensure that the infrared can enter the auxiliary heating area through the probe hole, then close the oven door, and turn on the microwave power switch to image 3 The schematic diagram of the sintering process curve shown in the figure shows that the sintering is completed, and the temperature of the sintered sample reaches 1550°C in about 30 minutes, and then it is kept for 10 minutes. The whole sintering process lasts about 40 minutes. After the sintering is completed, it is cooled to room temperature with the furnace....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com