Conductive adhesive, solar cell string and preparation method of solar cell string

A solar cell and conductive adhesive technology, applied in the field of solar cells, can solve problems such as yield reduction, cell cracking, and fragmentation, and achieve good conductivity, low curing temperature, and reduced bending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

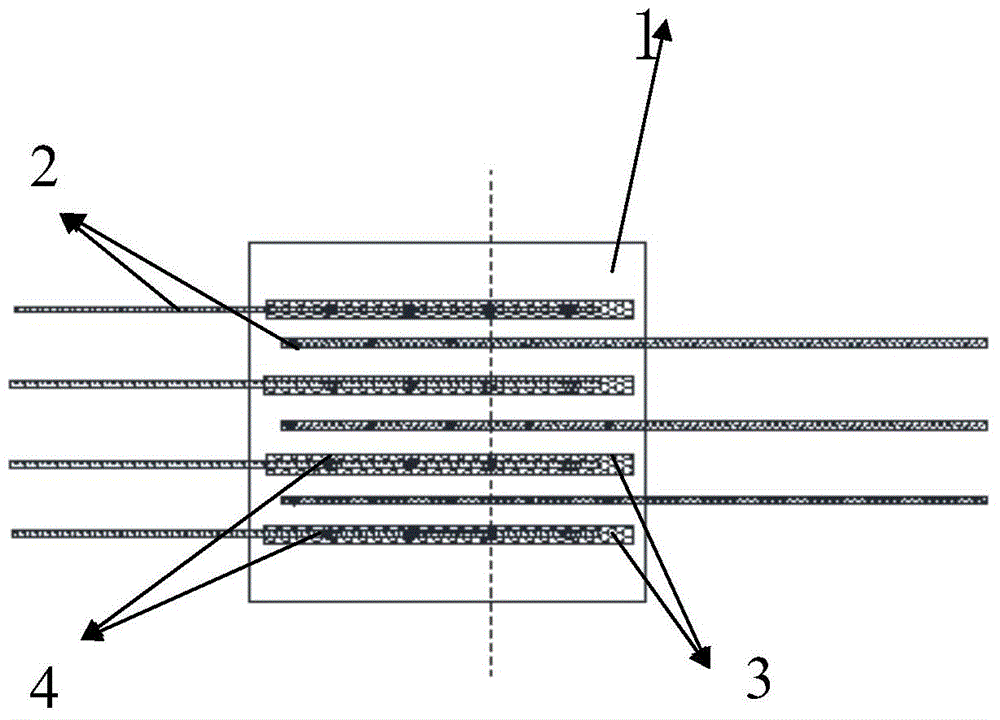

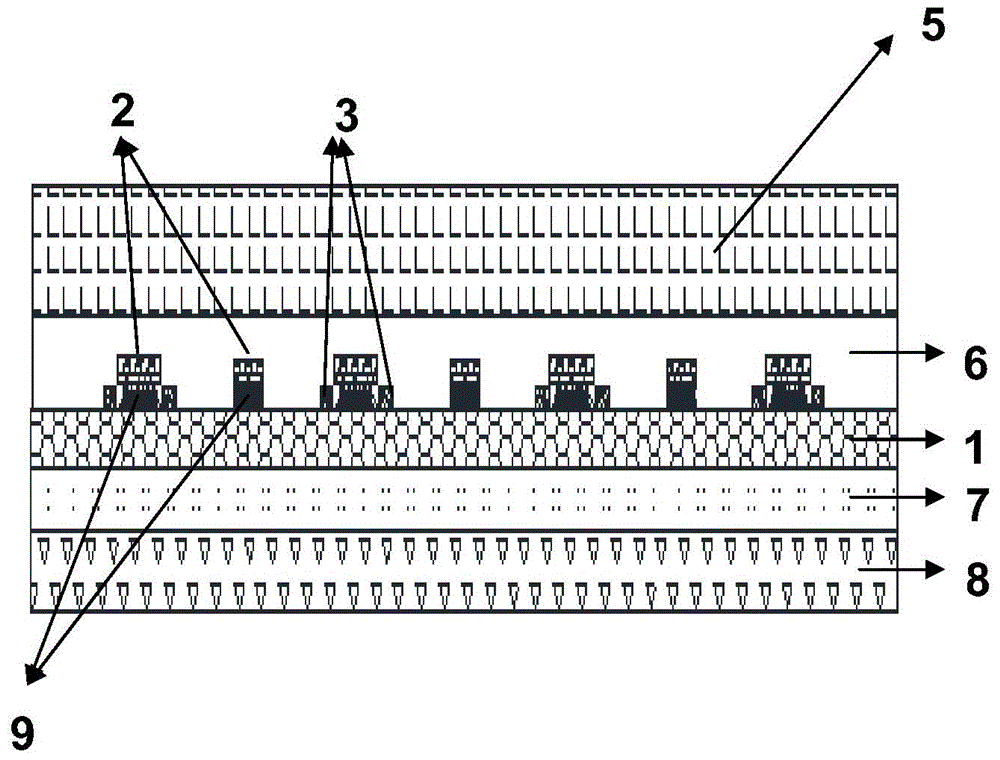

[0054] The present invention also provides a method for preparing the above-mentioned solar battery string, comprising: laying conductive adhesive on the solder joints of the soldering strips, then laying a viscous insulating material between the soldering joints, placing the battery slices, heating the conductive adhesive and pressing the battery slices and the soldering ribbons at the same time , to get the solar cell string.

[0055] Wherein, the conductive adhesive and the viscous insulating material are the same as those described above, and will not be repeated here. The welding ribbon can be a welding ribbon well-known to those skilled in the art, and there is no special limitation.

[0056] Spread conductive glue at the solder joints of the solder strips, and then lay viscous insulating material between the solder joints to prevent the battery sheet, heat the conductive glue and press the battery sheet and the solder ribbon at the same time, the heating temperature is ...

Embodiment 1

[0064] 1.1 50 parts by weight of polyhydroxyethyl methacrylate (weight-average molecular weight is 150000, degree of dispersion Mw / Mn=2.5), 40 parts by weight of silver powder with a particle diameter of 50nm, 1 part by weight of anti-aging agent Zhuohou B900 / Stir and mix ESC-ES680A, 0.5 parts by weight of anti-ultraviolet agent Tongcai UV-531 and 0.5 parts by weight of leveling agent Wacker WK-9336, and vacuum fill to obtain conductive adhesive.

[0065] 1.2 Spread the conductive adhesive obtained in 1.1 with a radius of 1.5mm on the super soft tinned copper strip solder joint with a width of 5mm and a thickness of 0.25mm, and then lay a width of 7.5mm and a thickness of 7.5mm on the solder joint. 0.2mm polyvinyl chloride tape, positioning and placing 60 monocrystalline silicon MWT cells with an efficiency of 20.1%, heating the conductive adhesive at 120°C for 15s while pressing the cells and ultra-soft tinned copper strips at a pressure of 0.1-5Pa, Connect the cells to get ...

Embodiment 2

[0070] 2.1 The bisphenol A epoxy resin of 50 parts by weight (weight-average molecular weight is 120000, degree of dispersion Mw / Mn=2.5), 48 parts by weight of silver powder with a diameter of 50nm, anti-aging agent DLTP of 1 part by weight, 0.5 parts by weight of anti-aging agent Stir and mix the UV agent HTUV105 and 0.5 parts by weight leveling agent Taiwan Changchun BP-05 / 24 / 26, and vacuum fill to obtain the conductive adhesive.

[0071] 2.2 Spread the conductive adhesive obtained in 2.1 with a radius of 1.5mm on the super soft tinned copper strip solder joints with a width of 5mm and a thickness of 0.25mm, and then lay a width of 7.5mm and a thickness of 7.5mm between the solder joints. 0.2mm polyvinyl chloride tape, positioning and placing 60 pieces of monocrystalline silicon MWT cells with an efficiency of 20.1%, heating the conductive adhesive at 150°C for 10s while pressing the cells and ultra-soft tinned copper strips with a pressure of 0.1-5Pa, Connect the cells to g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com