Metal oxide hollow nanometer particle-embedded nitrogen-doped nanometer foamy carbon synthesis method

A nano-particle and nano-foam technology, which is applied in the synthesis field of nitrogen-doped nano-foam carbon, can solve the problems of poor electrical conductivity and poor structural stability, and achieve the effects of environmental protection, easy large-scale production and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Dissolve 1.5g ferric nitrate nonahydrate and 1g polyvinylpyrrolidone (K30, molecular weight: 40000) in 20mL deionized water, and dissolve the resulting mixed solution in 100 o Dry under C, and the gained solid is ground into a powder;

[0021] (2) The powder prepared in step (1) is heated to 700°C in nitrogen flow o C, control the heating rate to 20 o C min -1 , The calcination time is 1 hour. After the reaction finishes, obtain silver-gray foamy carbon macrobody;

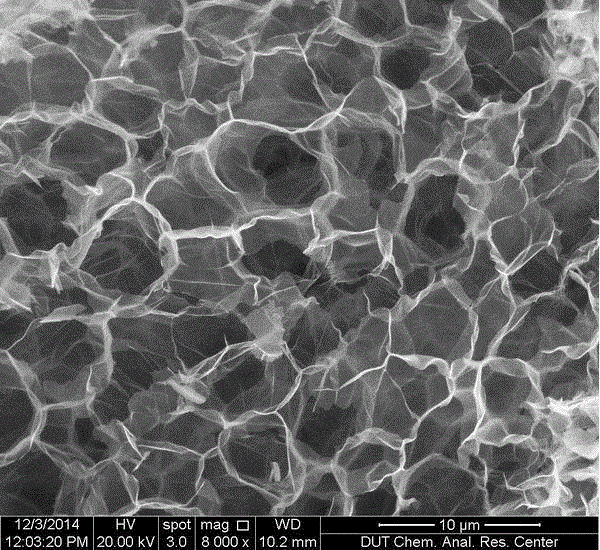

[0022] (3) the carbon foam prepared in step (2) is heated to 290 in air o C, the calcination time is 3 hours, and the foamed carbon embedded with ferric oxide hollow nanoparticles is obtained. Its macropore diameter distribution is between 5-8μm, the pore wall thickness is about 50nm, the carbon content is about 22wt.%, the nitrogen content is about 1%, and the specific surface area is 230m 2 g -1 .

Embodiment 2

[0024] (1) Dissolve 1.5g nickel nitrate hexahydrate and 1g polyvinylpyrrolidone (K30, molecular weight: 40000) in 20mL deionized water, and dissolve the resulting mixed solution in 100 o Dry under C, and the gained solid is ground into a powder;

[0025] (2) The powder prepared in step (1) is heated to 700°C in nitrogen flow o C, control the heating rate to 5 o C min -1 , The calcination time is 1 hour. After the reaction finishes, obtain silver-gray foamy carbon macrobody;

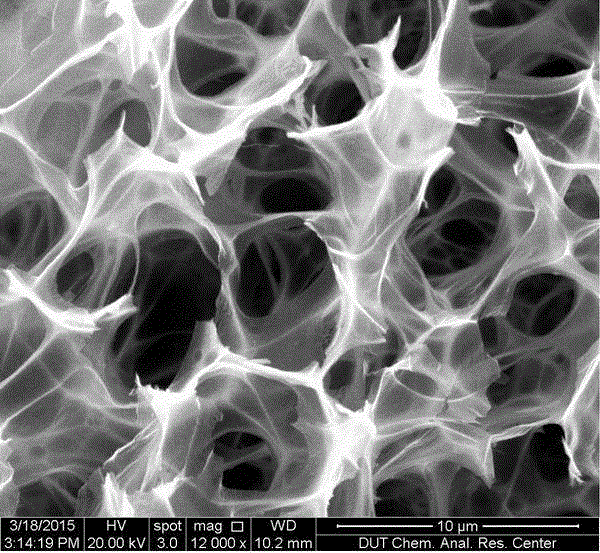

[0026] (3) the carbon foam prepared in step (2) is heated to 290 in air o C, the calcination time is 3 hours, and the carbon foam embedded with nickel oxide hollow nanoparticles is obtained. The pore size distribution of its macropores is between 5-10μm, the pore wall thickness is about 60-100nm, the carbon content is about 29wt.%, and the size of nickel oxide hollow nanoparticles is mainly distributed between 10-40nm.

Embodiment 3

[0028] (1) Dissolve 1.5g of cobalt nitrate hexahydrate and 1g of polyvinylpyrrolidone (K30, molecular weight: 40000) in 20mL of deionized water, and dissolve the resulting mixed solution in 100 o Dry under C, and the gained solid is ground into a powder;

[0029] (2) The powder prepared in step (1) is heated to 700°C in nitrogen flow o C, control the heating rate to 5 o C min -1 , The calcination time is 1 hour. After the reaction finishes, obtain silver-gray foamy carbon macrobody;

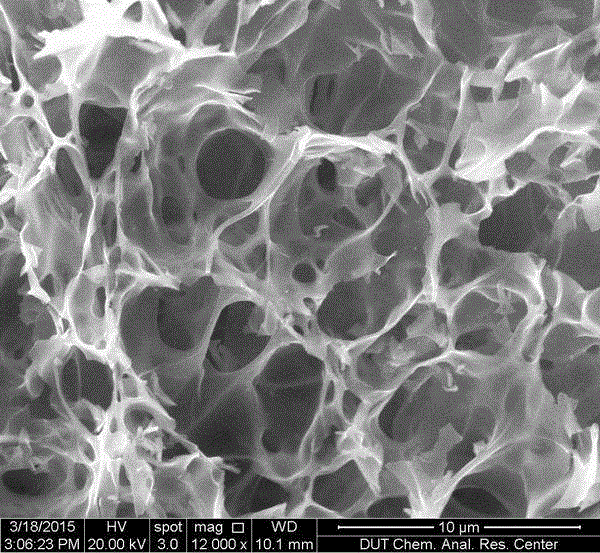

[0030] (3) the carbon foam prepared in step (2) is heated to 200 in air o C, the calcination time is 3 hours, and the foamed carbon embedded with ferric oxide hollow nanoparticles is obtained. Its macropore diameter is about 5-9μm, the pore wall thickness is about 70nm, the carbon content is about 24wt.%, the nickel oxide content is about 76wt.%, the cobalt oxide hollow nano-particle size is between 5-15nm, and the specific surface area is 260m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

| Hole wall thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com