Surface coating system of fiber reinforced ceramic matrix composite and its preparation method

A composite material and fiber reinforced technology, which is applied in the field of high temperature resistant fiber reinforced ceramic matrix composite materials, can solve the problems of loss, insufficient density of yttrium silicate coating and low preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

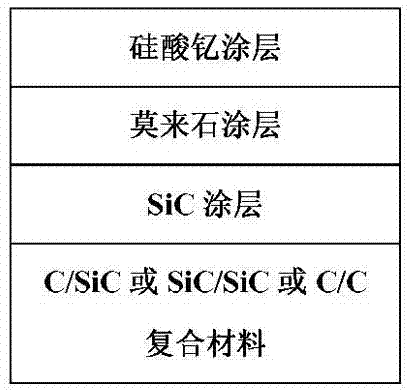

[0072] A kind of high temperature and anti-oxidation surface coating system of the present invention, such as figure 1 shown. The surface coating system is arranged on the surface of a C / C composite material substrate, and includes a SiC inner coating, a mullite intermediate layer and an yttrium silicate outer coating arranged sequentially from bottom to top.

[0073] In this embodiment, the thickness of the SiC coating is 20 μm; in the chemical composition of the mullite coating, Al 2 o 3 with SiO 2 The mass ratio is 2.13:1, the thickness of the mullite coating is 60 μm; the yttrium silicate coating is Y 2 Si 2 o 7 Single-phase coating with a single layer thickness of 80 μm.

[0074] A preparation method of the C / C composite material surface coating system of the above-mentioned present embodiment, comprising the following steps:

[0075] S1. Raw materials for preparing SiC coating slurry: according to the SiC powder / silicone resin volume ratio of 1:3 (the density of t...

Embodiment 2

[0095] A kind of high temperature and anti-oxidation surface coating system of the present invention, such as figure 1 shown. The surface coating system is arranged on the surface of a SiC / SiC composite material substrate, including a SiC layer, a mullite coating and an yttrium silicate coating arranged sequentially from bottom to top.

[0096] In this embodiment, the thickness of the SiC coating is 50 μm; in the chemical composition of the mullite coating, Al 2 o 3 with SiO 2 The mass ratio is 3.55:1, the thickness of the mullite coating is 50 μm; the yttrium silicate coating is Y 2 SiO 5 Single-phase coating with a single layer thickness of 50 μm.

[0097] A kind of preparation method of the composite material surface coating system of above-mentioned present embodiment, comprises the following steps:

[0098] S1. Raw materials for preparing SiC coating slurry: SiC powder / silicone resin volume ratio 1: 1.5 (the density of the silicone resin used in this embodiment is 1...

Embodiment 3

[0118] A kind of high temperature and anti-oxidation surface coating system of the present invention, such as figure 1 shown. The surface coating system is arranged on the surface of a C / SiC composite material substrate, and includes a SiC inner coating, a mullite intermediate layer and an yttrium silicate outer coating arranged sequentially from bottom to top.

[0119] In this embodiment, the thickness of the SiC coating is 40 μm; in the chemical composition of the mullite coating, Al 2 o 3 with SiO 2 The mass ratio is 2.55:1, the thickness of the mullite coating is 50 μm; the yttrium silicate coating is 70wt% Y 2 Si 2 o 7 +30wt%Y 2 SiO 5 Mixed-phase single-layer coating with a single-layer thickness of 100 μm.

[0120] A kind of preparation method of the composite material surface coating system of above-mentioned present embodiment, comprises the following steps:

[0121] S1. Raw materials for preparing SiC coating slurry: according to the SiC powder / silicone resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com