Macroelement water soluble fertilizer and preparation method therefor

A large amount of elements, water-soluble fertilizer technology, applied in the direction of fertilization equipment, fertilizer mixture, application, etc., can solve the problems of poor chemical safety and stability, many impurities or sediment, single nutrient, etc., to achieve uniform appearance, no environmental pollution, The effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

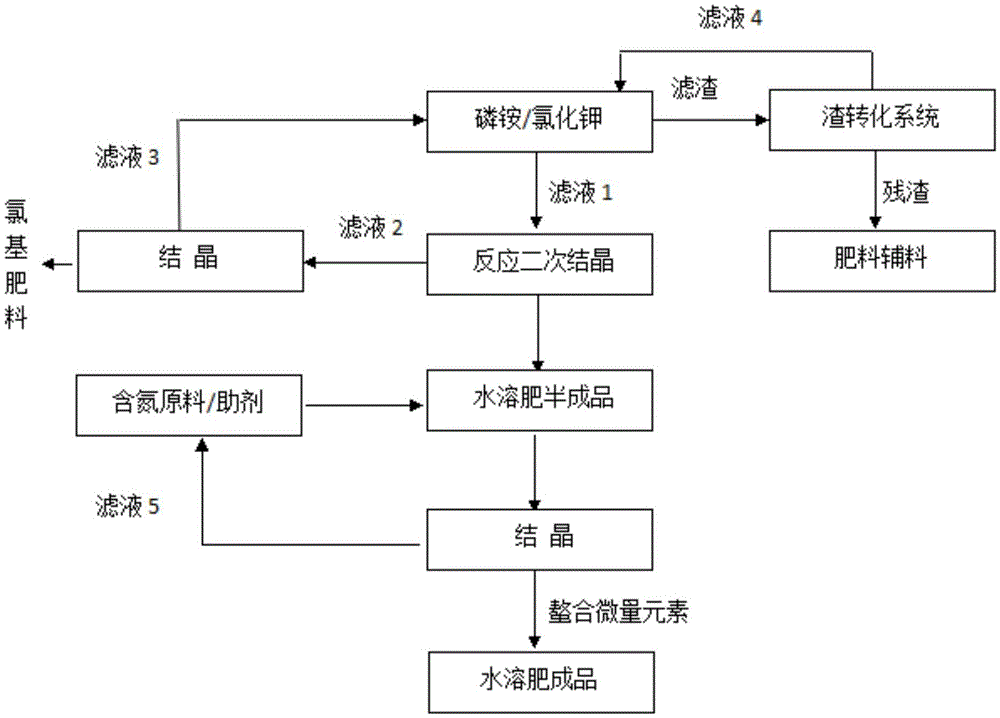

Method used

Image

Examples

Embodiment 1

[0056] ①Add 42.5kg of agricultural ammonium phosphate and 13.5kg of agricultural potassium chloride to 80L of water, then add liquid ammonia to adjust the pH value to 7.0, and form a saturated solution with some filter residues coexisting at 20°C, and filter at 20°C to obtain Filtrate 1 and 9.7kg filter residue 1;

[0057] 2. Add 18.7kg agricultural potassium chloride to filtrate 1 and heat to 80°C, then add 4mol / L phosphoric acid to adjust pH=3, stir the crystals separated out at this time and filter while hot at 50°C to obtain semi-finished water-soluble fertilizer crystals ( Weight 45kg, N%=4.22%, P 2 o 5 %=51.71%, K20%=32.34%, Cl%=1.26%) and filtrate 2,

[0058] ③ Add 36.2kg of agricultural ammonium phosphate to filtrate 2, then add liquid ammonia at 20°C to adjust the pH to 7.0, return 7.2kg of filter residue to the residue conversion system, cool and crystallize the filtrate, and filter at 20°C. This filtrate is called filtrate 3. Dry at 80°C to obtain chlorine-based ...

Embodiment 2

[0062] ①Add 40.3kg of agricultural ammonium phosphate and 14.2kg of agricultural potassium chloride to 80L of water, then add potassium hydroxide to adjust the pH value to 6.0, and form a saturated solution with some filter residues at 20°C, and filter at 20°C, Obtain filtrate 1 and 8.1kg filter residue 1;

[0063] 2. Add 19.6kg agricultural potassium chloride to filtrate 1 and heat to 80°C, then add 4mol / L phosphoric acid to adjust pH=4, stir the precipitated crystals and filter while hot at 50°C to obtain semi-finished water-soluble fertilizer crystals ( Weight 43.5kg, N%=3.82%, P 2 o 5 %=43.98%, K20%=40.23%, Cl%=2.74%) and filtrate 2,

[0064] ③Add 34.3kg of agricultural ammonium phosphate to filtrate 2, add potassium hydroxide at 20°C to adjust the pH value to 6.0, return 6.8kg of filter residue to the residue conversion system, cool and crystallize the filtrate, and filter at 20°C, this filtrate is called filtrate 3 . Dry at 80°C to obtain chlorine-based fertilizer, w...

Embodiment 3

[0068] ① Add 42.5 kg of agricultural ammonium phosphate and 9.8 kg of agricultural potassium chloride to 80 L of water, then add liquid ammonia to adjust the pH value to 7.0, and form a saturated solution with some filter residues coexisting at 20 ° C, and filter at 20 ° C to obtain Filtrate 1 and 9.5kg filter residue 1;

[0069] 2. Add 16.2kg of agricultural potassium chloride to filtrate 1 and heat to 80°C, then add 4mol / L phosphoric acid to adjust pH=5, stir the precipitated crystals and filter while hot at 50°C to obtain the water-soluble fertilizer semi-finished crystals ( Weight 41.1kg, N%=4.25%, P 2 o 5 %=50.6%, K20%=24.48%, Cl%=0.39%) and filtrate 2,

[0070] ③Add 37.3kg of agricultural ammonium phosphate to filtrate 2, then add liquid ammonia at 20°C to adjust the pH=7.0, return 7.5kg of filter residue to the residue conversion system, cool and crystallize the filtrate, and filter at 20°C, this filtrate is called filtrate 3. Dry at 80°C to obtain chlorine-based fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com