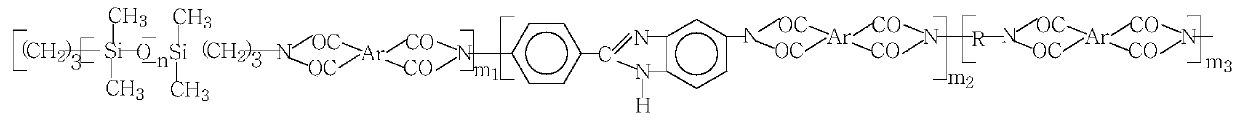

A kind of biphenyl type polyimide humidity sensitive capacitor and preparation method thereof

A biphenyl type polyimide, humidity-sensitive capacitor technology, used in capacitors, variable capacitors, capacitors that change the capacitance by non-mechanical methods, etc., can solve the problems of poor sensitivity, accuracy and resolution, and achieve The effect of convenient source, easy molecular weight and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

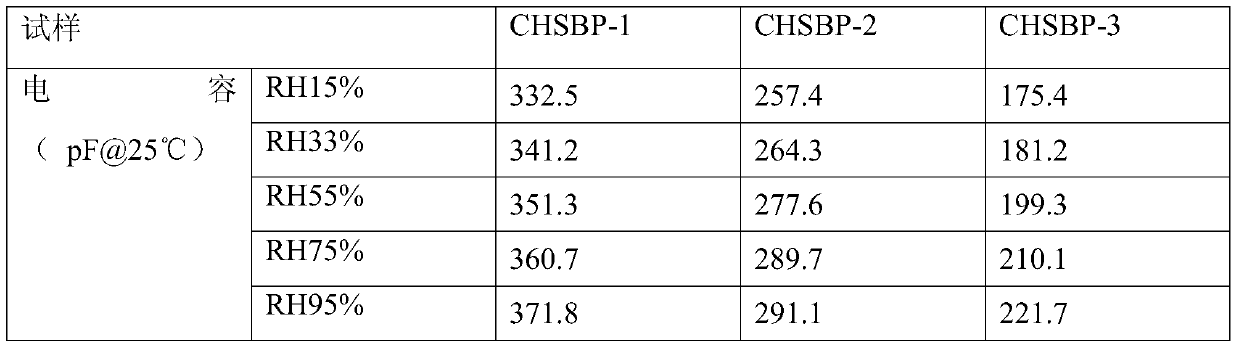

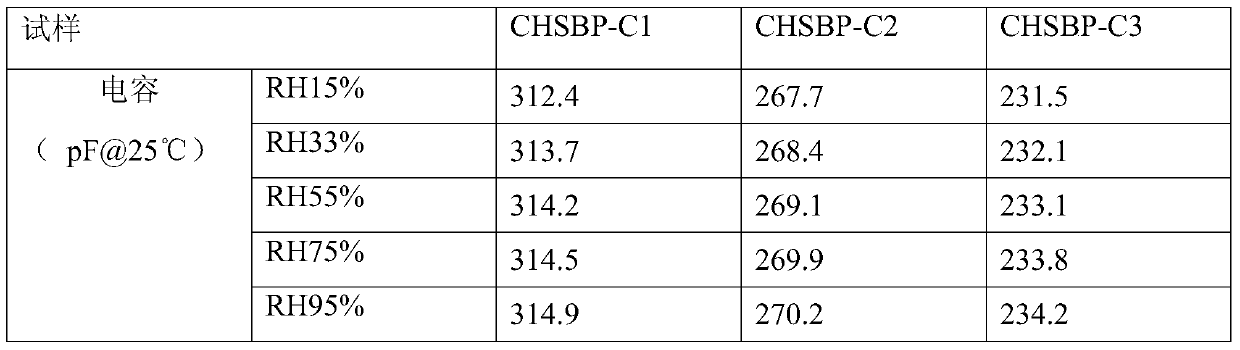

Embodiment 1

[0038] 2.16 grams (0.01 moles) of 3,3'-diamino-4,4'-dihydroxybiphenyl (DAHBP), 22.00 grams (0.11 moles) of 3,4'-diaminodiphenyl ether, 37.82 grams (0.122 moles ) 3,3',4,4'-tetracarboxydiphenyl ether dianhydride and 248 grams of N,N-dimethylformamide were put into the reactor, and after stirring and reacting for 2 hours at 0°C, 309 grams of viscous The transparent and homogeneous biphenyl type moisture-sensitive polyimide precursor solution is designated as HSBP-1.

Embodiment 2

[0040] 2.16 grams (0.01 moles) of 3,3'-diamino-4,4'-dihydroxybiphenyl (DAHBP), 29.2 grams (0.10 moles) of 1,3-bis(4-aminophenoxy)benzene and 31.70 gram (0.10 mol) 2,6-bis(4-aminophenoxy) benzonitrile, 62.62 gram (0.213 mol) 3,3',4,4'-tetracarboxy biphenyl dianhydride, 254 gram N,N - Dimethylformamide and 500 grams of N-methyl-2-pyrrolidone were put into a reaction kettle, and after stirring and reacting at 5°C for 5 hours, 879 grams of viscous, transparent and homogeneous biphenyl type moisture-sensitive polyimides were obtained Precursor solution, denoted as HSBP-2.

Embodiment 3

[0042] 2.16 g (0.01 mol) of 3,3'-diamino-4,4'-dihydroxybiphenyl (DAHBP), 64.8 g (0.15 mol) of 4,4'-bis(4-aminophenoxy)diphenyl Sulfone, 39.28 grams (0.122 moles) of 3,3',4,4'-tetracarboxybenzophenone dianhydride and 21.84 grams (0.042 moles) of 2,2-bis(3,4-dicarboxyphenyl)propane di Anhydride, 640 grams of N,N-dimethylacetamide were put into the reaction kettle, and after stirring and reacting for 4 hours at 2°C, 768 grams of viscous transparent homogeneous biphenyl type moisture-sensitive polyimide precursor solution was obtained. Denoted as HSBP-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com