Thermoplastic calcium carbonate toughening particles and preparation method therefor

A calcium carbonate and thermoplastic technology, applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of modifier shedding failure, product strength impact, and easy particle agglomeration, etc., to achieve the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

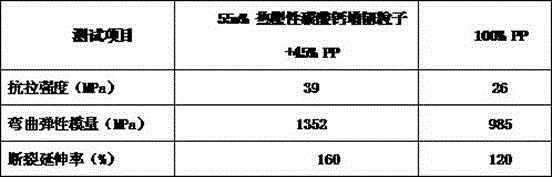

Examples

Embodiment 1

[0024] 1) Add 5 parts by weight of liquid polymer polyisobutylene with an average molecular weight of 200,000 and 80 parts by weight of nanoporous calcium carbonate with through holes into a closed reaction mixer, set the negative pressure to 2.0 MPa at room temperature, and stir at a high speed of 100 rpm After dispersing for 20 minutes, polyisobutylene is adsorbed in the microporous network of nanoporous calcium carbonate;

[0025] 2) Add 8 parts by weight of butadiene and 15 parts by weight of styrene to the material obtained in step 1), add tetrahydrofurfuryl alcohol and butyl lithium during high-speed stirring at 800-1200 rpm, and heat at 60-80 ° C Polymerization occurs under the environment, the styrene random copolymer is connected with the polyisobutylene adsorbed in the nanoporous calcium carbonate network, and coated on the surface of the calcium carbonate particles to obtain a thermoplastic calcium carbonate toughened particle. Wherein the addition of tetrahydrofurf...

Embodiment 2

[0030] 1) Add 3 parts by weight of liquid polymer polyisobutylene with an average molecular weight of 300,000 and 85 parts by weight of nanoporous calcium carbonate with more than 20% through holes into a closed reaction mixer. Stir and disperse at high speed for 15 minutes, polyisobutene is adsorbed in the microporous network of nanoporous calcium carbonate;

[0031] 2) Add 5 parts by weight of butadiene and 15 parts by weight of styrene to the material obtained in step 1), add tetrahydrofurfuryl alcohol and butyllithium during high-speed stirring at 800-1200 rpm, and heat at 60-80 ° C Polymerization occurs under the environment, the styrene random copolymer is connected with the polyisobutylene adsorbed in the nanoporous calcium carbonate network, and is coated on the surface of the calcium carbonate particles to form a firm coating layer, wherein the addition of tetrahydrofurfuryl alcohol is butanediol 3% of the mass of alkene, and the addition of butyllithium is 5% of the ...

Embodiment 3

[0034] 1) Add 45 parts by weight of liquid polymer polyisobutylene and 90 parts by weight of nanoporous calcium carbonate to a closed reaction mixer, set the negative pressure at room temperature to 3.5MPa, stir and disperse at a high speed of 100rpm for 20 minutes, polyisobutene is adsorbed Within the microporous network of nanoporous calcium carbonate;

[0035] 2) Add 8 parts by weight of butadiene and 10 parts by weight of styrene to the material obtained in step 1), add tetrahydrofurfuryl alcohol and butyl lithium during high-speed stirring at 800-1200 rpm, and heat at 60-80 ° C Polymerization occurs under the environment, the styrene random copolymer is connected with the polyisobutylene adsorbed in the nanoporous calcium carbonate network, and is coated on the surface of the calcium carbonate particles to form a firm coating layer, wherein the addition of tetrahydrofurfuryl alcohol is butanediol 2.5% of the mass of alkene, and the addition of butyllithium is 7% of the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com