Processing method of heat-resistant stainless steel annealing tank and prepared annealing tank

A technology of heat-resistant stainless steel and processing method, applied in the direction of improving process efficiency, can solve problems such as breakage and failure, and achieve the effects of good sealing performance, high thermal strength, and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

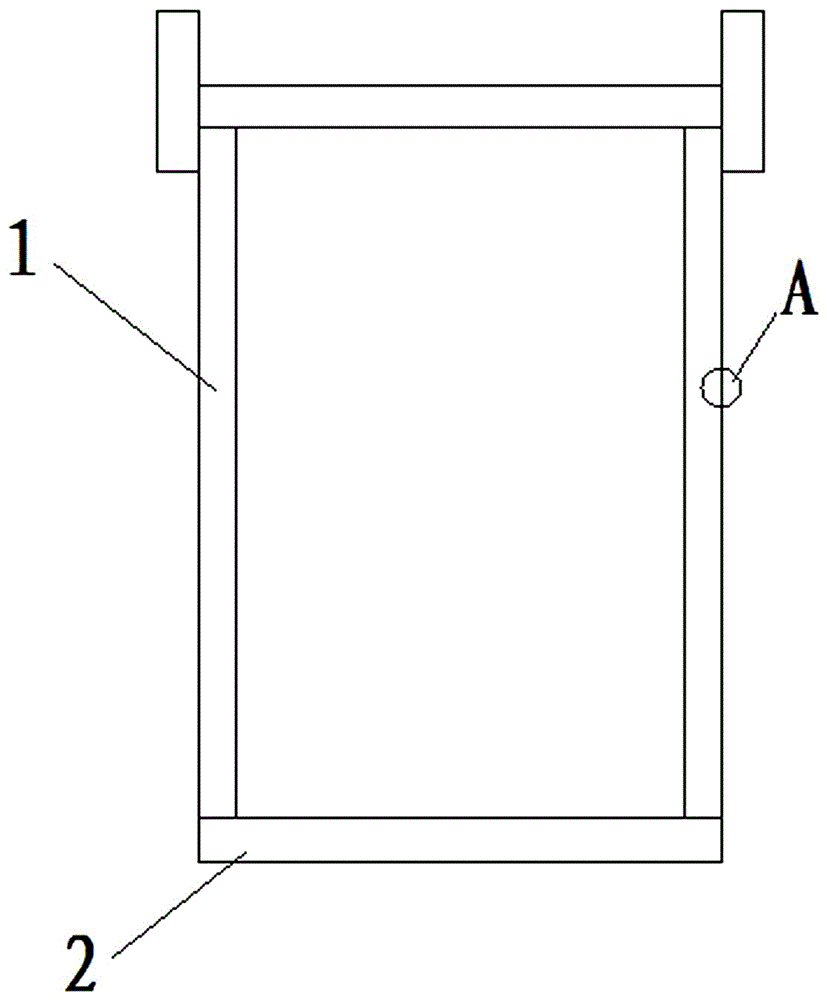

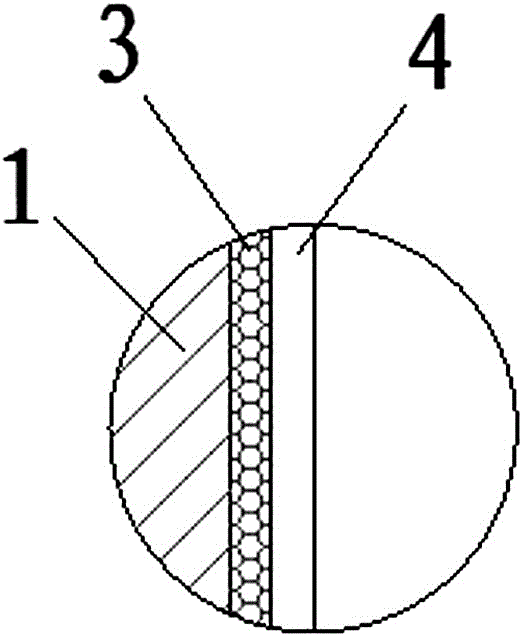

[0023] Embodiment 1: A heat-resistant stainless steel annealing tank, comprising a tank bottom 2 and a tank body 1 welded together, the tank body 1 is a large-diameter seamless stainless steel pipe with a thickness of 18mm, and the outer surface of the tank body 1 is provided with quartz sand Infiltrate the fusion layer 3 and the quartz sand layer 4.

[0024] The tank body 1 is alloy steel, and its composition and weight percentage are: 3% nickel, 10% chromium, 1% silicon, 1% manganese, 0.6% copper, 0.01% aluminum, 0.1% molybdenum, 0.03% niobium, nitrogen 0.1%, carbon 0.25%, and the rest is iron.

[0025] The processing method of the heat-resistant stainless steel annealing tank is as follows: A. The tank body is formed by centrifugal casting, using waste stainless steel as a base material, adding a high-temperature-resistant and corrosion-resistant alloy, passing through an intermediate frequency induction furnace, melting and refining at a high temperature of 1600 °C, and mo...

Embodiment 2

[0029] Embodiment 2: A heat-resistant stainless steel annealing tank, the tank body 1 is a large-diameter seamless stainless steel pipe with a thickness of 20 m, and the outer surface of the tank body 1 is provided with a quartz sand permeable fusion layer 3 and a quartz sand layer 4 .

[0030] The tank body 1 is alloy steel, and its composition and weight percentage are: nickel 5%, chromium 14%, silicon 2%, manganese 1.5%, copper 0.4%, aluminum 0.02%, molybdenum 0.15%, niobium 0.01%, nitrogen 0.2%, carbon 0.28%, and the rest is iron.

[0031]The processing method of the heat-resistant stainless steel annealing tank is as follows: A. The tank body is formed by centrifugal casting, using waste stainless steel as a base material, adding a high-temperature-resistant and corrosion-resistant alloy, passing through an intermediate frequency induction furnace, melting and refining at a high temperature of 1600 °C, and molten steel After the test is up to standard, start the centrifug...

Embodiment 3

[0035] Embodiment 3: A heat-resistant stainless steel annealing tank, the tank body 1 is a large-diameter seamless stainless steel pipe with a thickness of 16 m, and the outer surface of the tank body 1 is provided with a quartz sand permeable fusion layer 3 and a quartz sand layer 4 .

[0036] The tank body 1 is alloy steel, and its composition and weight percentage are: 7% nickel, 18% chromium, 1.5% silicon, 1.3% manganese, 0.2% copper, 0.03% aluminum, 0.2% molybdenum, 0.02% niobium, nitrogen 0.3%, carbon 0.3%, and the rest is iron.

[0037] The processing method of the heat-resistant stainless steel annealing tank is as follows: A. The tank body is formed by centrifugal casting, using waste stainless steel as a base material, adding a high-temperature-resistant and corrosion-resistant alloy, passing through an intermediate frequency induction furnace, melting and refining at a high temperature of 1600 °C, and molten steel After the test is up to standard, start the centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com