A kind of method for preparing magnesium carbonate trihydrate whisker by ultrasonic wave

A magnesium carbonate trihydrate and ultrasonic technology, applied in the field of mineral processing, can solve the problems of high energy consumption, long reaction time, low yield of magnesium carbonate trihydrate whiskers, etc., to achieve increased reaction temperature, fast reaction speed, and no need for heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

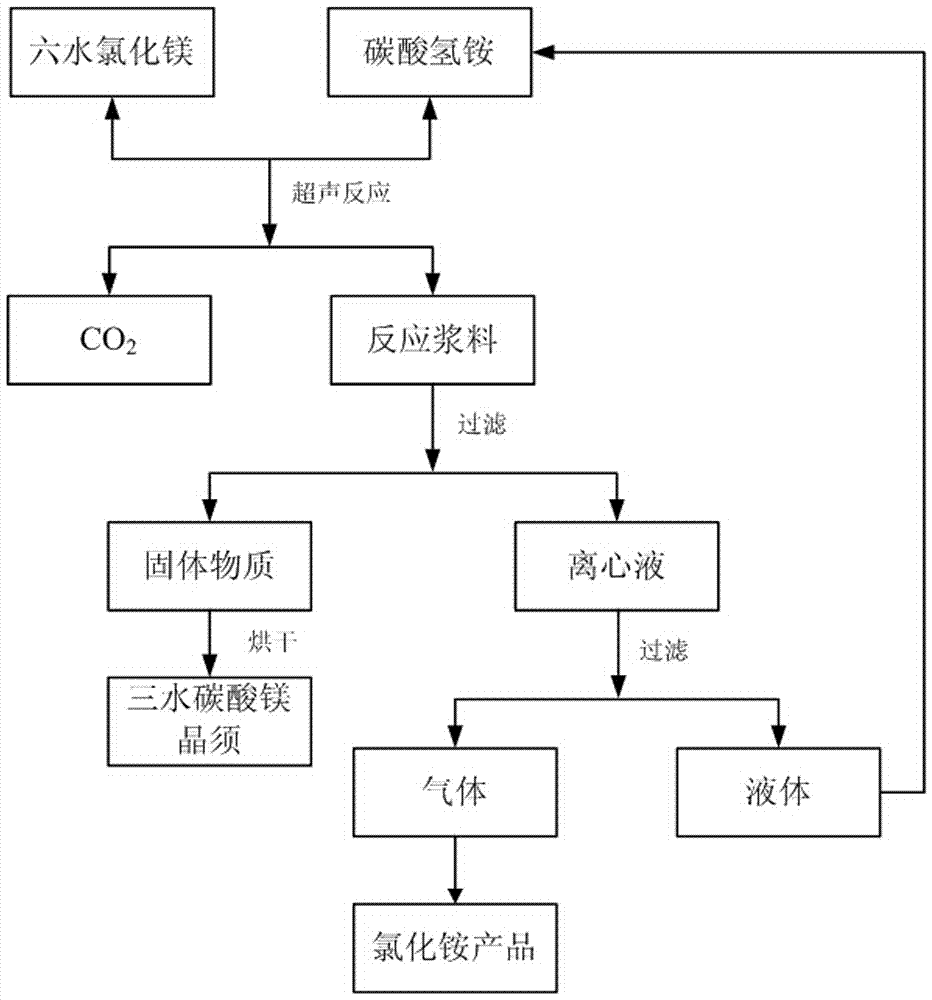

[0027] The technical scheme of this embodiment is as figure 1 shown, follow the steps below:

[0028] (1) Using water as a solvent, make magnesium chloride hexahydrate into a 0.5mol / L solution, and ammonium bicarbonate into a 1.0mol / L solution;

[0029] (2) After moving the prepared magnesium chloride hexahydrate solution into the reaction tank, add the ammonium bicarbonate solution into the magnesium chloride hexahydrate solution at 20°C, and stir at the same time, the stirring speed is 360r / min, and the addition is completed in 5 seconds to obtain mixed materials;

[0030] (3) Move the reaction tank containing the mixed material to the ultrasonic chemical reactor, and react for 20 minutes under the action of ultrasonic waves, collect the gas generated during the reaction to obtain CO 2 product;

[0031] (4) Centrifuge and dehydrate the reaction slurry in the reaction tank in a low-speed centrifuge to obtain solid matter and centrifugate; heat the centrifuge at 100°C for 6...

Embodiment 2

[0033] The technical scheme of this embodiment is as figure 1 shown, follow the steps below:

[0034] (1) Using water as a solvent, make magnesium chloride hexahydrate into a 0.75mol / L solution, and ammonium bicarbonate into a 1.5mol / L solution;

[0035] (2) After moving the prepared magnesium chloride hexahydrate solution into the reaction tank, add the ammonium bicarbonate solution into the magnesium chloride hexahydrate solution at 25°C, and stir at the same time. The stirring speed is 120~360r / min, and the addition is completed in 8 seconds. , to get the mixed material;

[0036] (3) Move the reaction tank containing the mixed material to the ultrasonic chemical reactor, and after reacting for 5 minutes under the action of ultrasonic waves, collect the gas generated during the reaction to obtain CO 2 product;

[0037] (4) Centrifuge and dehydrate the reaction slurry in the reaction tank in a low-speed centrifuge to obtain solid matter and centrifugate; heat the centrifug...

Embodiment 3

[0039] The technical scheme of this embodiment is as figure 1 shown, follow the steps below:

[0040] (1) Using water as a solvent, make magnesium chloride hexahydrate into a 1.0mol / L solution, and ammonium bicarbonate into a 2.0mol / L solution;

[0041] (2) After moving the prepared magnesium chloride hexahydrate solution into the reaction tank, add the ammonium bicarbonate solution into the magnesium chloride hexahydrate solution at 30°C, while stirring at the same time, the stirring speed is 120r / min, and the addition is completed in 10 seconds to obtain mixed materials;

[0042] (3) Move the reaction tank containing the mixed materials to the ultrasonic chemical reactor, and react for 15 minutes under the action of ultrasonic waves, collect the gas generated during the reaction to obtain CO 2 product;

[0043](4) Centrifuge and dehydrate the reaction slurry in the reaction tank in a low-speed centrifuge to obtain solid matter and centrifugate; heat the centrifuge at 120°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com