Inverse micelle method in use for degrading cellulose

A technology for degrading cellulose and reverse micelles, applied in the direction of fermentation, etc., can solve the problems of insufficient glucose yield and poor solubility, and achieve the effects of improving cellulose enzymatic hydrolysis efficiency, increasing concentration and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

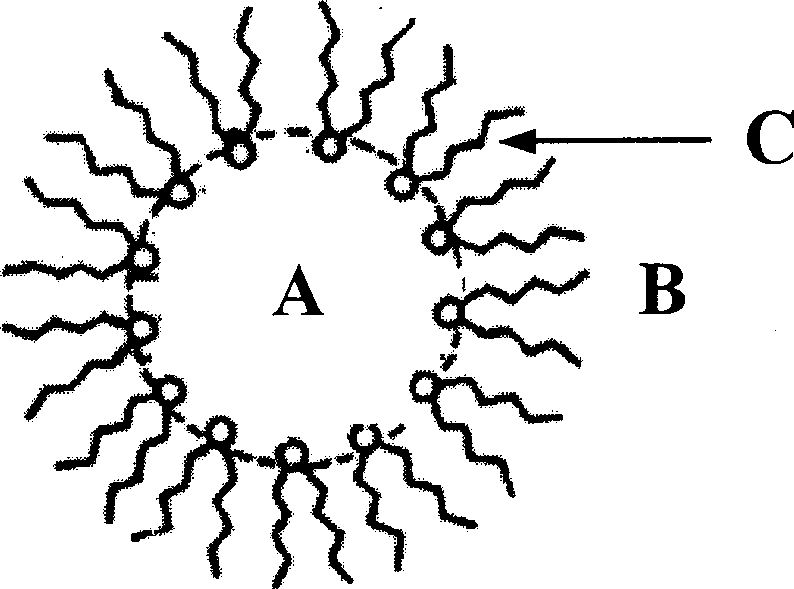

Image

Examples

Embodiment 1

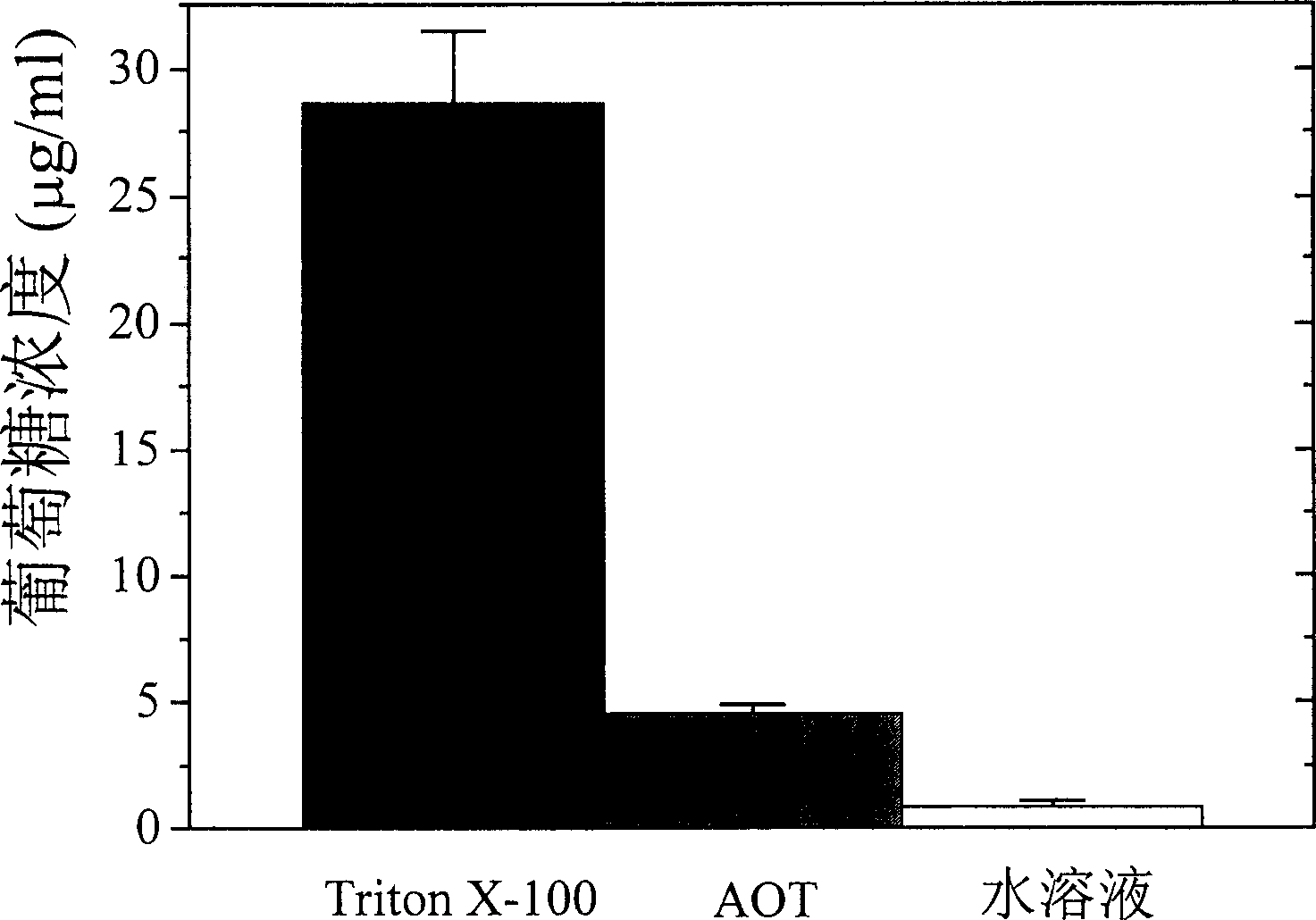

[0021] Example 1: Method for degrading microcrystalline cellulose using reverse micelles formed by surfactant AOT

[0022] 1. At room temperature (25°C), prepare 1ml of cellulase buffer solution with pH 6.0 (refer to the principle and application of biochemical technology for the preparation of buffer solution), and the concentration is 380μM, which is recorded as solution A;

[0023] 2. Dissolve 0.15mmol of 2-ethylhexyl sodium succinate (AOT) in 3ml of isooctane, shake vigorously and let it stand for later use, and record it as solution B;

[0024] 3. Take 14μl from solution A and mix with solution B, shake vigorously and then let it stand for 20 seconds. After it is uniform and transparent, it is a reverse micelle system containing cellulase molecules;

[0025] 4. After keeping the above system at 50°C for 10 minutes, add 10mg of microcrystalline cellulose, and fully react for 10 minutes in a constant temperature shaker (50°C, 220rpm);

[0026] 5. After that, add 140μl of phosph...

Embodiment 2

[0028] Example 2: Method for degrading microcrystalline cellulose using reverse micelles formed by the surfactant Triton X-100

[0029] 1. At room temperature (25°C), prepare 1ml of cellulase buffer solution with pH 6.0 (refer to the principle of biochemical technology and its application for the preparation of buffer solution), and the concentration is 400μM, which is recorded as solution A;

[0030] 2. Dissolve 0.15mmol of polyoxyethylene alkyl phenyl ether (Triton X-100) in 1ml of xylene, then add 2ml of n-hexanol, shake vigorously, and let it stand for use, which is recorded as solution B;

[0031] 3. Take 18μl from solution A and mix with solution B, shake it vigorously and let it stand for about 15 seconds. After it is uniform and transparent, it will be a reverse micelle system containing enzyme molecules;

[0032] 4. After keeping the system at 50°C for 10 minutes, add 10mg of microcrystalline cellulose, and fully react for 10 minutes in a constant temperature shaker (50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com