Front packaging membrane of solar battery and application thereof

A technology of solar cells and front film, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of limiting the single working time of drones, the low light absorption efficiency of photovoltaic cells, and the difficulty in meeting the power supply demand, so as to improve the cost Membrane effect, optimized arrangement order, effect of increased light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

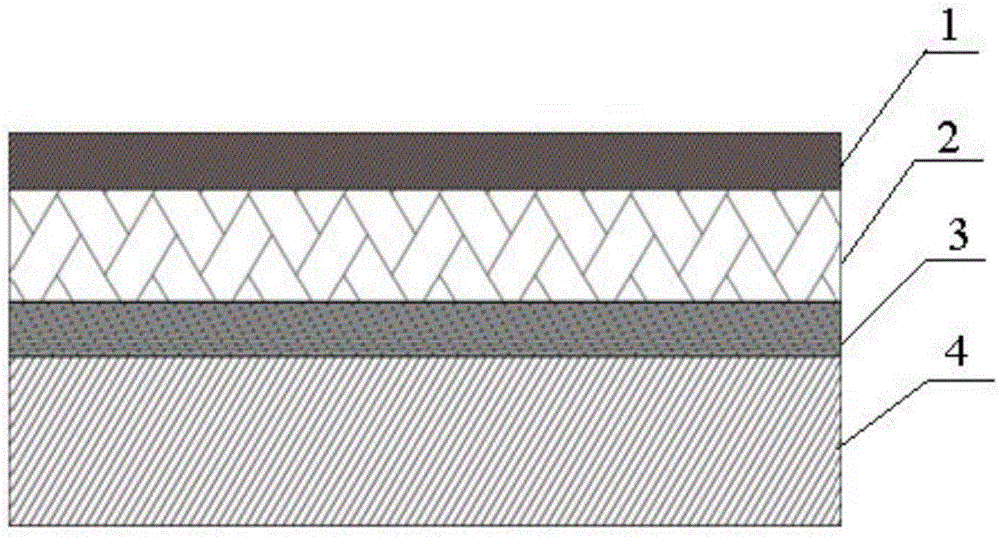

[0039] The film before solar cell encapsulation described in this embodiment comprises a polytetrafluoroethylene modified film with a thickness of 50 μm and a MgF film with a thickness of 95 nm formed by sequential vapor deposition on the modified polytetrafluoroethylene film. 2 Thin film, TiO with a thickness of 650nm 2 -ZrO 2 -La 2 o 3 Mixture film, and Al with a thickness of 75nm 2 o 3 film.

[0040] The preparation method of the above solar cell encapsulation film comprises the following steps:

[0041] (1) Mix kerosene with a mass ratio of 4:0.1 and sodium perfluorooctanoate evenly to form a composite solvent; in the kerosene, the content of isoparaffins is 90wt%, and the content of normal paraffins is 8wt%;

[0042] (2) Add the composite solvent of step (1) into the polytetrafluoroethylene powder, stir at a constant temperature of 14°C at a speed of 20r / min for 0.5h, and then mature in a nitrogen atmosphere at a constant temperature of 24°C for 10h , to get cooked...

Embodiment 2

[0054] The film before solar cell encapsulation described in this embodiment comprises a polytetrafluoroethylene modified film with a thickness of 75 μm and a MgF film with a thickness of 90 nm formed by sequential vapor deposition on the modified polytetrafluoroethylene film. 2 Thin film, TiO with a thickness of 500nm 2 -ZrO 2 -La 2 o 3 Mixture film, and Al with a thickness of 80nm 2 o 3 film.

[0055] The preparation method of the above solar cell encapsulation film comprises the following steps:

[0056] (1) mixing kerosene and toluene with a mass ratio of 5:0.1 to form a composite solvent; in the kerosene, the content of isoparaffins is 86wt%, and the content of normal paraffins is 11wt%;

[0057] (2) Add the composite solvent of step (1) to the polytetrafluoroethylene powder, stir at a constant temperature of 10°C at a speed of 50r / min for 0.5h, and then mature in a nitrogen atmosphere at a constant temperature of 32°C for 12h , to get cooked material;

[0058] Wh...

Embodiment 3

[0069] The film before solar cell encapsulation described in this embodiment comprises a polytetrafluoroethylene modified film with a thickness of 100 μm and a MgF film with a thickness of 93 nm formed by sequential vapor deposition on the modified polytetrafluoroethylene film. 2 Thin film, TiO with a thickness of 800nm 2 -ZrO 2 -La 2 o 3 Mixture film, and Al with a thickness of 70nm 2 o 3 film.

[0070] The preparation method of the above solar cell encapsulation film comprises the following steps:

[0071] (1) mixing kerosene and polyalkenyl succinimide with a mass ratio of 4.5: 0.1 to form a composite solvent, then adding bisphenol A epoxy resin to the composite solvent to obtain a mixture;

[0072] Wherein, the mass ratio of the bisphenol A type epoxy resin and the kerosene in the composite solvent is 2:5; in the kerosene, the content of isoparaffins is 87wt%, and the content of normal paraffins is 9wt%;

[0073] (2) Add the mixture of step (1) to the polytetrafluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com