High-effective composite corrosion and scale inhibitor being suitable for high-calcium and -alkali water and preparation method thereof

A technology of corrosion and scale inhibitor, copper corrosion inhibitor, applied in chemical instruments and methods, complex/solubilizer treatment, scale removal and water softening, etc., can solve the problem of unsatisfactory zinc stabilization effect and poor scale inhibition effect , poor corrosion inhibition effect, etc., to achieve excellent corrosion and scale inhibition performance, environmental protection, and easy compounding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

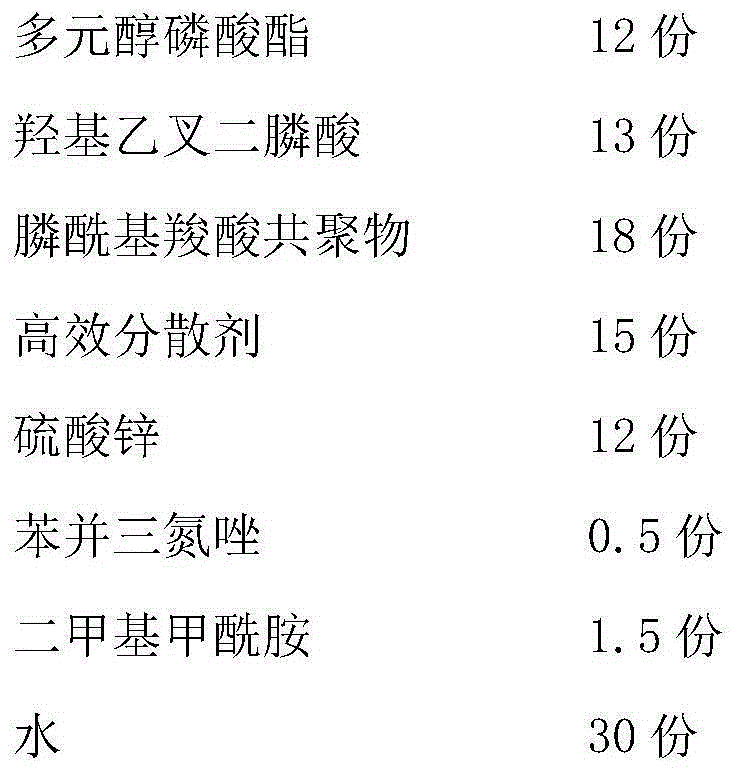

[0035] Recipe 1:

[0036] The weight content of each component of the composite slow-release scale inhibitor is:

[0037]

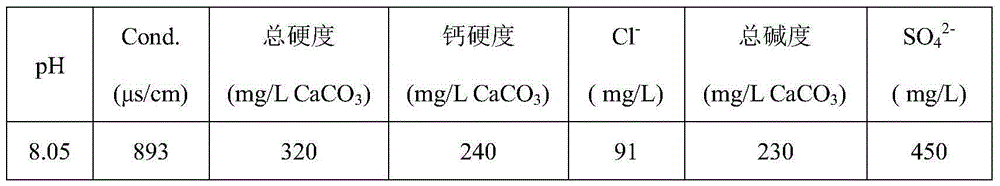

[0038] Experimental raw water quality:

[0039]

[0040] According to the above water quality, carry out the rotating plate test, run for 3 days, the water temperature is 45 ℃, add the experimental raw water to supplement the evaporation water loss, add the compound slow-release scale inhibitor 30mg / L, after the experiment, the concentration ratio of the water quality is about 2.5 times, and it is tested by the experiment The corrosion rate of the carbon steel coupon is 0.0187mm / a, which meets the requirements of the industrial circulating cooling water treatment design specification (GB50050--2007).

[0041] According to the standard of "Determination of Scale Inhibition Performance of Water Treatment Agents--Calcium Carbonate Deposition Method" (GB-T16632-2008), the scale inhibition rate was measured, and the scale inhibition rate was 87%.

Embodiment 2

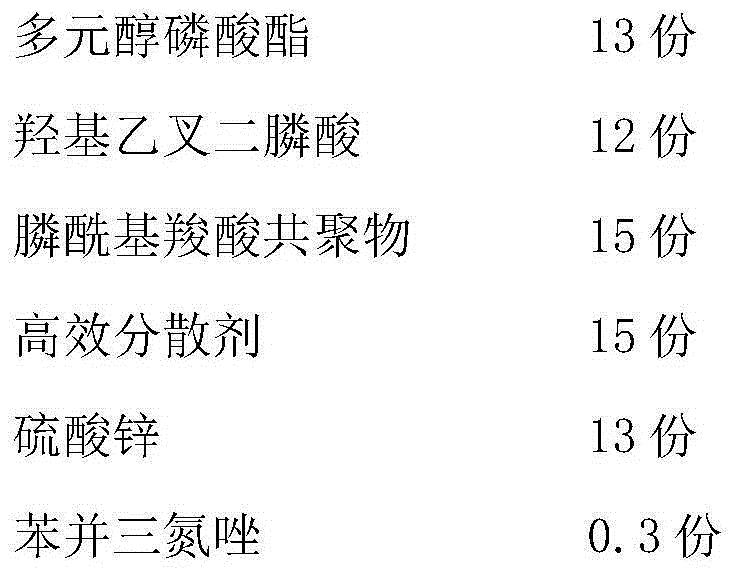

[0043] Recipe 2:

[0044] The weight content of each component of the composite slow-release scale inhibitor is:

[0045]

[0046]

[0047] Experimental raw water quality:

[0048]

[0049] According to the above water quality, carry out the rotating plate test, run for 5 days, the water temperature is 45 ℃, add the experimental raw water to supplement the evaporation water loss, add the compound slow-release scale inhibitor 30mg / L, after the experiment, the concentration ratio of the water quality is about 4 times, and it is tested by the experiment The corrosion rate of the carbon steel coupon is 0.0235mm / a, which meets the requirements of the industrial circulating cooling water treatment design specification (GB50050--2007).

[0050] According to the standard of "Determination of Scale Inhibition Performance of Water Treatment Agents--Calcium Carbonate Deposition Method" (GB-T16632-2008), the scale inhibition rate was measured, and the scale inhibition rate was 9...

Embodiment 3

[0052] Recipe 3:

[0053] The weight content of each component of the composite slow-release scale inhibitor is:

[0054]

[0055] Experimental raw water quality:

[0056]

[0057] According to the above water quality, the rotating plate test was carried out. After 7 days of operation, the water temperature was 45°C. The experimental raw water was added to supplement the evaporation water loss, and the compound slow-release scale inhibitor was added at 30mg / L. After the experiment, the water concentration was about 5.5 times. The corrosion rate of the carbon steel coupon is 0.0287mm / a, which meets the requirements of the industrial circulating cooling water treatment design specification (GB50050--2007).

[0058] According to the standard of "Determination of Scale Inhibition Performance of Water Treatment Agents--Calcium Carbonate Deposition Method" (GB-T16632-2008), the scale inhibition rate was measured, and the scale inhibition rate was 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com