Method for extracting pure type II collagen from chicken cartilage

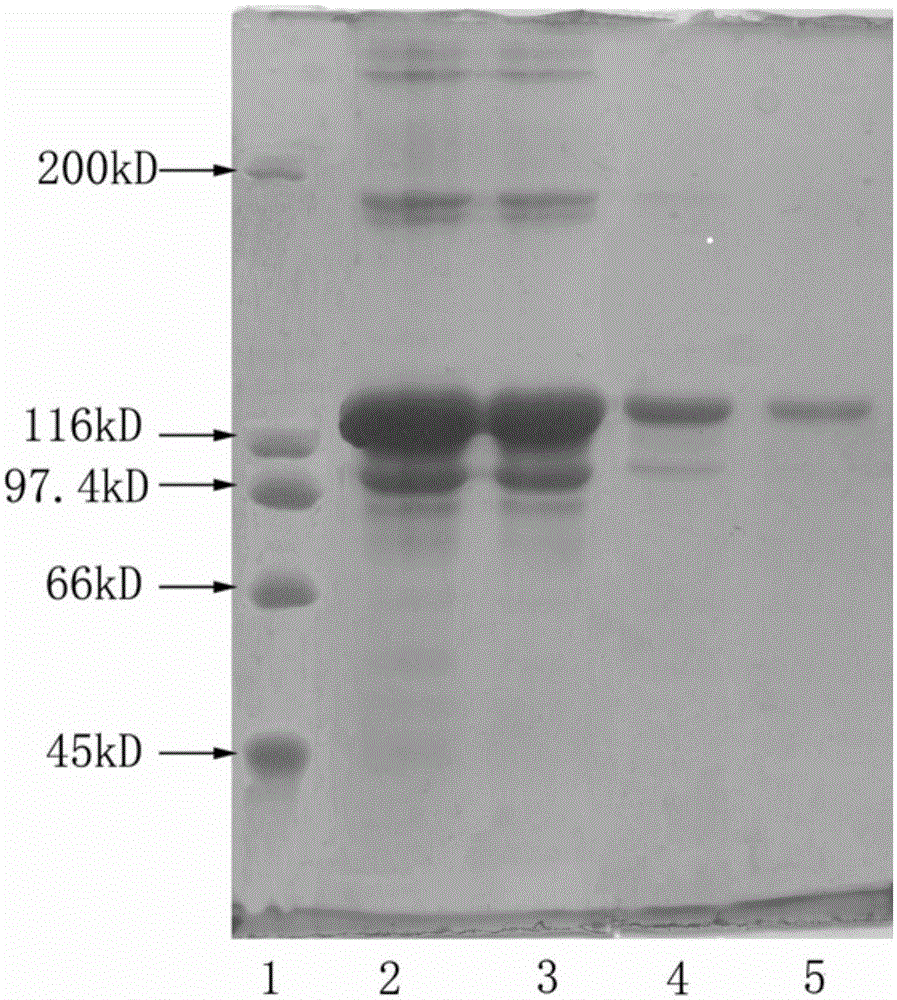

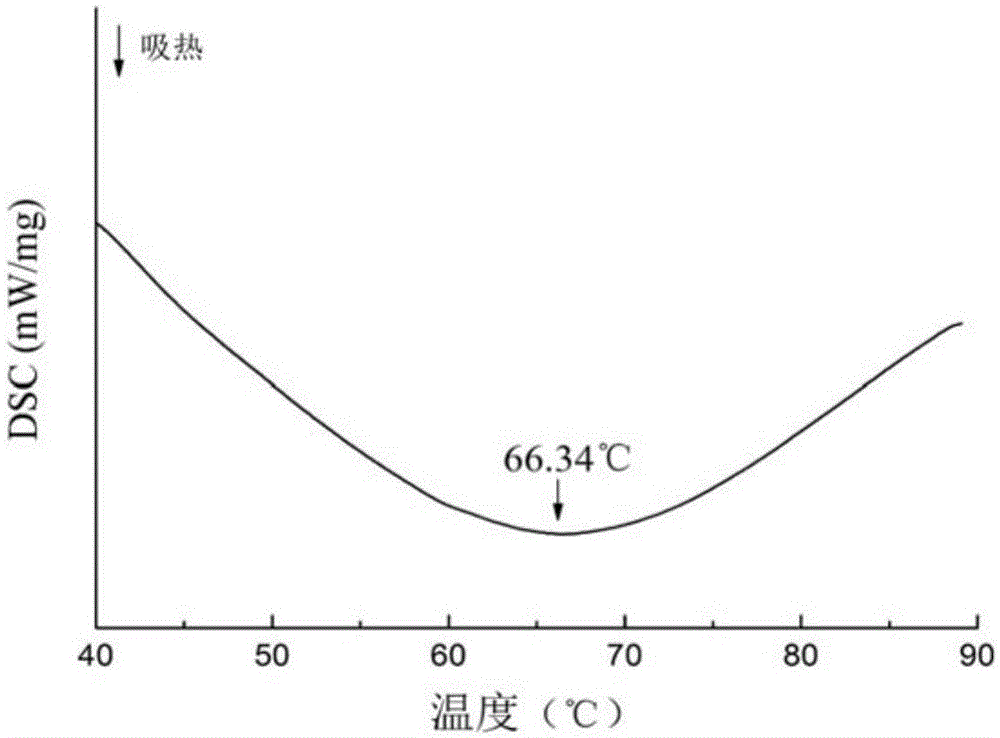

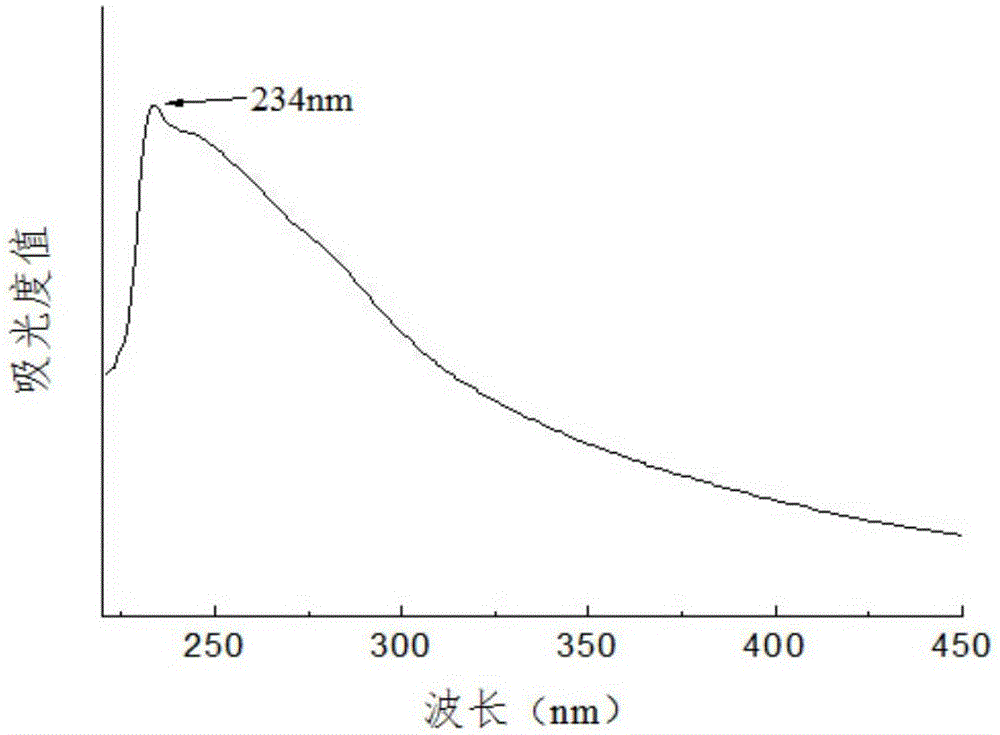

A technology for chicken cartilage and collagen, which is applied in the field of biomedical material preparation, can solve the problems of inability to remove type IX, type X, type XI collagen and type II collagen, the extraction method is complex, and the type of collagen is not single. The effect of large-scale production, good biocompatibility, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Pretreatment of cartilage

[0047] Remove residual meat and other non-cartilage components from the surface of fresh cartilage, weigh 100g and wash it fully with normal saline, add 10 times of degreasing agent (chloroform:methanol=1:1) to soak, replace the degreasing solution every 12h, pour it out after 60h solution, washed 3 times with cold ultrapure water, then soaked the cartilage in cold ultrapure water overnight, took it out and mashed it to obtain cartilage slurry;

[0048] 2) Removal of foreign proteins:

[0049] Prepare 4mol / LNaCl-0.05mol / LTris-HCl mixed solution H1, the pH is 7.5, add the above-mentioned mixed solution H1 to the cartilage slurry obtained in step 1), the ratio of solid to liquid is 1:25, stir for 24h, and centrifuge , the speed of the centrifuge is 9000r / min, the time is 10min, the temperature is 4°C, the precipitate is left, and the precipitate is washed repeatedly with cold ultrapure water for 5 times to obtain the precipitate;

[0050] ...

Embodiment 2

[0059] 1) Pretreatment of cartilage

[0060] Remove residual meat and other non-cartilage components from the surface of fresh cartilage, weigh 160g, wash it fully with normal saline, add 30 times of degreasing solution (chloroform:methanol=1:3) to soak, replace the degreasing solution every 10h, and pour it out after 36h Solution, wash 5 times with cold deionized water, then soak the cartilage in cold deionized water overnight, take out and mash to obtain cartilage slurry;

[0061] 2) Removal of foreign proteins:

[0062] Prepare 4mol / LNaCl-0.05mol / LTris-HCl mixed solution H1, the pH is 7.5, add the above-mentioned mixed solution H1 to the cartilage slurry obtained in step 1), the ratio of solid to liquid is 1:30, stir for 12h, and centrifuge , the speed of the centrifuge is 6000r / min, the time is 25min, the temperature is 4°C, the precipitate is left, and the precipitate is washed repeatedly with cold deionized water 4 times to obtain the precipitate;

[0063] Prepare 4mol...

Embodiment 3

[0072] 1) Pretreatment of cartilage

[0073] Remove residual meat and other non-cartilage components from the surface of fresh cartilage, weigh 120g and wash it fully with normal saline, add 20 times of degreasing solution (chloroform:methanol=1:4) to soak, replace the degreasing solution every 15h, and pour it out after 24h solution, washed 4 times with cold deionized water, then soaked the cartilage in cold deionized water overnight, took it out and mashed it to obtain cartilage slurry;

[0074] 2) Removal of foreign proteins:

[0075]Prepare 4mol / LNaCl-0.05mol / LTris-HCl mixed solution H1, the pH is 7.5, add the above-mentioned mixed solution H1 to the cartilage slurry obtained in step 1), the material-liquid ratio is 1:15, stir for 36h, and centrifuge , the speed of the centrifuge is 8000r / min, the time is 15min, the temperature is 4°C, the precipitate is left, and the precipitate is washed repeatedly with cold deionized water for 3 times to obtain the precipitate;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com