Biomimetic synthesis method of Fe3O4/Fe/C nano composite battery electrode material

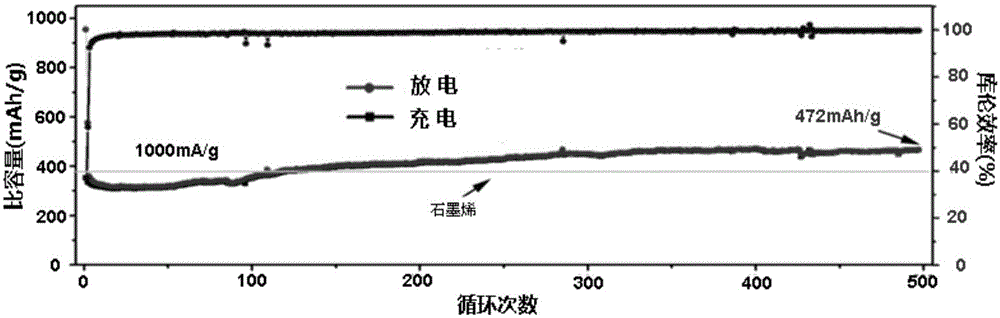

A battery electrode, biomimetic synthesis technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of poor cycle performance and rate performance, and achieve the effects of good rate performance, good cycle performance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

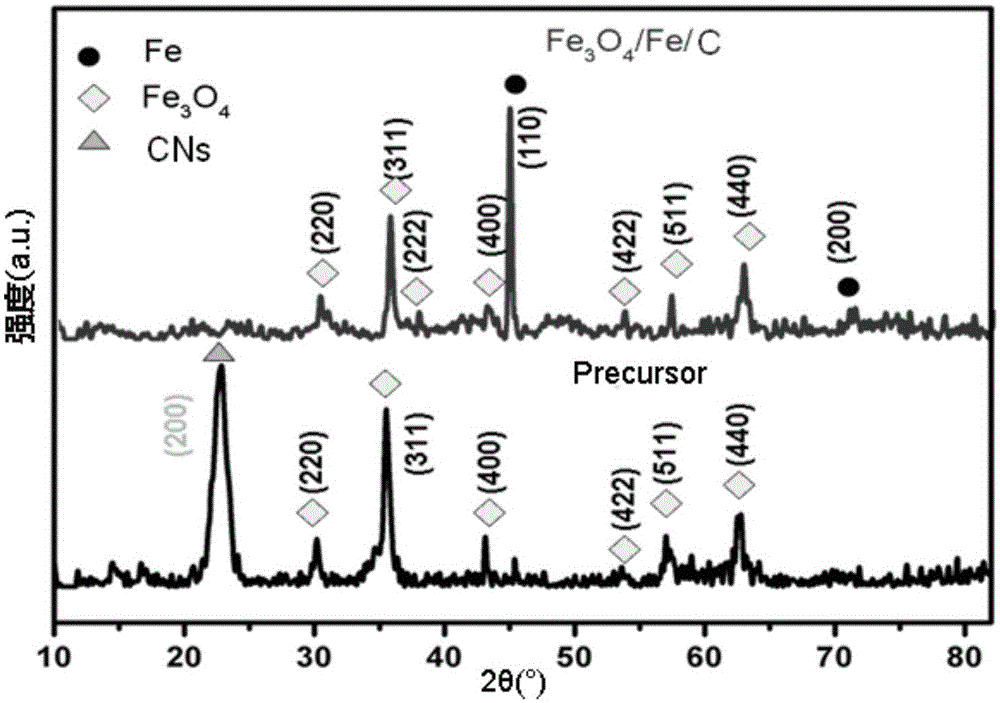

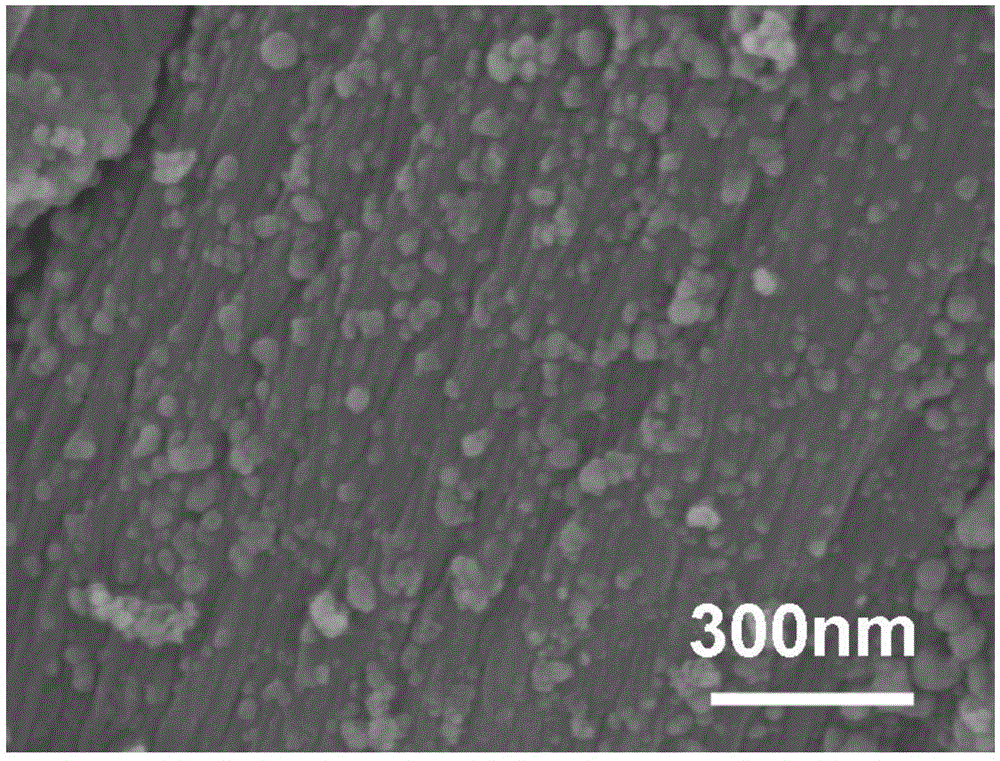

[0040] a kind of Fe 3 o 4 The biomimetic synthesis method of / Fe / C nanocomposite battery electrode material, the preparation steps are as follows:

[0041] (1) Cut 3g of cotton into pieces with a length of 5mm and soak it in 45mL of sulfuric acid solution with a substance concentration of 15mol / L, keep it warm at 45°C for 40 minutes, separate the solid from the liquid, wash the solid with water until it is neutral, and place it at 60°C Drying at a lower temperature, the active nanocellulose is obtained, and the active nanocellulose is used as a biological template.

[0042] (2)) the active nanocellulose 1g that step (1) makes is soaked in the FeCl that 80ml concentration is 0.069mol / L 3 ·6H 2 In O aqueous solution, stir at room temperature for 2h, then add mass concentration 25wt% ammonia solution to adjust pH=8, form Fe(OH) 3 For the mixed precipitate with cellulose, the pH-adjusted mixed solution was hydrothermally treated at 180°C for 4 hours, separated from solid and l...

Embodiment 2

[0051] a kind of Fe 3 o 4 The biomimetic synthesis method of / Fe / C nanocomposite battery electrode material, the preparation steps are as follows:

[0052] (1) Cut 3 g of cotton into pieces with a length of 5 mm and soak them in 45 mL of sulfuric acid solution with a substance concentration of 15 mol / L, heat at 30°C for 60 minutes, separate the solid from the liquid, wash the solid with water until it is neutral, and place it at 60°C Drying at a lower temperature, the active nanocellulose is obtained, and the active nanocellulose is used as a biological template.

[0053] (2)) the active nanocellulose 1g that step (1) makes is soaked in the FeCl that 80ml concentration is 0.069mol / L 3 ·6H 2 In O aqueous solution, stir at room temperature for 2h, then add mass concentration 25wt% ammonia solution to adjust pH=8, form Fe(OH) 3 For the mixed precipitate with cellulose, the pH-adjusted mixed solution was hydrothermally treated at 160°C for 6 hours, separated from solid and liq...

Embodiment 3

[0057] a kind of Fe 3 o 4 The biomimetic synthesis method of / Fe / C nanocomposite battery electrode material, the preparation steps are as follows:

[0058] (1) Cut 3g of cotton into pieces with a length of 5mm and soak it in 45mL of sulfuric acid solution with a substance concentration of 15mol / L, heat it at 60°C for 30 minutes, separate the solid from the liquid, wash the solid with water until it is neutral, and place it at 60°C Drying at a lower temperature, the active nanocellulose is obtained, and the active nanocellulose is used as a biological template.

[0059] (2)) the active nanocellulose 1g that step (1) makes is soaked in the FeCl that 80ml concentration is 0.069mol / L 3 ·6H 2 In O aqueous solution, stir at room temperature for 2h, then add mass concentration 25wt% ammonia solution to adjust pH=8, form Fe(OH) 3 For the mixed precipitate with cellulose, the pH-adjusted mixed solution was hydrothermally treated at 200°C for 2 hours, separated from solid and liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com