A kind of preparation method of thermistor ceramic ink for inkjet printing

A thermistor and ceramic ink technology, which is applied in ink, applications, household appliances, etc., can solve the problems of low solid content of ink, not suitable for industrial production, easy reunion, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

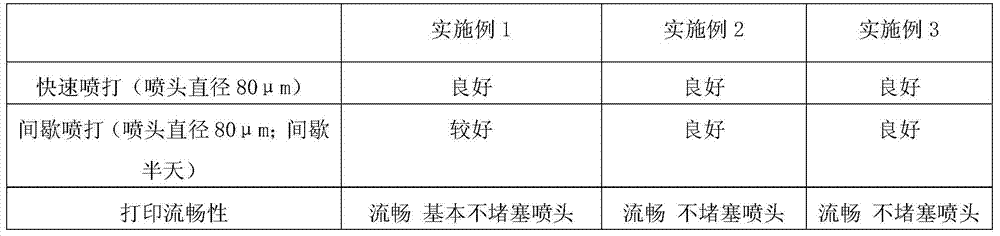

Examples

Embodiment 1

[0020] a. Preparation of thermistor powder: the conventional solid-phase ball milling method is adopted, and the specific steps are:

[0021] To analyze pure MnO 2 , Ni 2 O 3 , Co 2 O 3 , Fe 2 O 3 , ZnO and CuO are two, three or four of them as raw materials, placed in a ball mill tank or agitating container, and then add the grinding balls and the dispersion medium is anhydrous ethanol or acetone, or directly add the dispersion medium anhydrous ethanol or Acetone to obtain a mixture;

[0022] Ball mill or stir the mixture at a speed of 50-450r / min for 8h, and dry it at a temperature of 50-120℃ to obtain a powder;

[0023] After the obtained powder is fully ground, it is calcined and ground at a temperature of 800-900°C, and passed through a 200-mesh screen to obtain thermistor powder, see Table 1;

[0024] b. Preparation of thermistor ceramic ink: disperse the thermistor powder in organic solvents, dispersants and adhesives, ultrasonically stir, and stand to form a uniform and stable...

Embodiment 2

[0031] a. Preparation of thermistor powder: using the reverse microemulsion method, the specific steps are:

[0032] Mix the emulsifier Triton X-100, the co-surfactant n-hexanol, and the oil phase cyclohexane in a beaker according to the proportions, and stir to form an emulsified system;

[0033] According to the volume ratio, the nitrate is two, three or four of cobalt nitrate, manganese nitrate, nickel nitrate, iron nitrate, and copper nitrate to configure a 0.5-3mol / L metal nitrate aqueous solution;

[0034] Add the obtained metal nitrate aqueous solution dropwise to the emulsification system, and stir uniformly to form a microemulsion system;

[0035] Place the obtained microemulsion system on a magnetic stirrer in a constant temperature water bath and magnetically stir;

[0036] Slowly drip ammonia water into the microemulsion system at the ratio of n (metal salt) / n (ammonia water) = 1:1.5, and react at a constant temperature for 4 hours to obtain the product;

[0037] Centrifuge t...

Embodiment 3

[0046] a. Preparation of thermistor powder: using conventional co-precipitation method, the specific steps are:

[0047] Mix two, three or four of the acetates into manganese acetate, cobalt acetate, nickel acetate, iron acetate, copper acetate, and zinc acetate according to the molar ratio, and dissolve them in deionized water to form 1-3mol / L The mixed solution, stir evenly;

[0048] Weigh oxalic acid and sodium hydroxide and mix them separately, add deionized water to completely dissolve oxalic acid and sodium hydroxide to obtain a mixed solution;

[0049] Drop the prepared mixed solution into the prepared acetate mixed solution at a speed of 0.5-2d / s while stirring. After the titration, the pH of the solution is between 1-2 to obtain the mixed solution;

[0050] The obtained mixed solution is aged for 10-12 hours, and centrifuged to obtain a precipitate;

[0051] Wash the obtained precipitate with deionized water and absolute ethanol, and dry at 100°C for 1-3 hours to obtain a drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com