A method for producing wet process phosphoric acid by-product α hemihydrate gypsum whiskers and high purity and high whiteness α hemihydrate gypsum whiskers

A technology of hemihydrate gypsum and wet-process phosphoric acid, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc., to achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

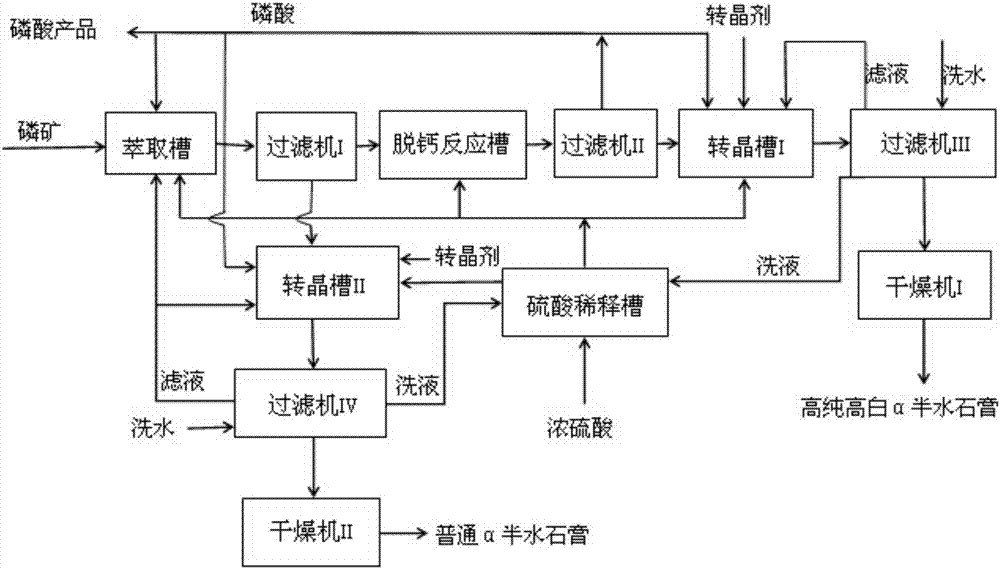

Image

Examples

Embodiment 1

[0043] Raw material 1: Phosphate rock, collection location: Kailin, Guizhou;

[0044] Raw material 2: sodium citrate, commercially available;

[0045] Raw material 3: aluminum sulfate, commercially available;

[0046] Raw material 4: sodium dodecylsulfonate, commercially available;

[0047] Raw material 5: sulfuric acid, concentration is 97%, commercially available;

[0048] The sulfuric acid solutions used in the examples are obtained by diluting concentrated sulfuric acid with a concentration of 97 wt%, and carried out in a sulfuric acid dilution tank.

[0049] A method for producing wet-process phosphoric acid byproduct α hemihydrate gypsum whiskers and high-purity and high whiteness α hemihydrate gypsum whiskers, comprising steps as follows:

[0050] (1) Add excess phosphoric acid and phosphate rock powder into the extraction tank, the solid-to-liquid mass ratio of phosphate rock powder and phosphoric acid is 1:17, the concentration of phosphoric acid is 20wt%, under th...

Embodiment 2

[0059] Raw material 1: Phosphate rock, collection location: Kailin, Guizhou;

[0060] Raw material 2: sodium citrate, commercially available;

[0061] Raw material 3: iron sulfate, commercially available;

[0062] Raw material 4: sulfuric acid, concentration is 97%, commercially available;

[0063] The sulfuric acid solutions used in the examples are obtained by diluting concentrated sulfuric acid with a concentration of 97 wt%, and carried out in a sulfuric acid dilution tank.

[0064] A method for producing wet-process phosphoric acid byproduct α hemihydrate gypsum whiskers and high-purity and high whiteness α hemihydrate gypsum whiskers, comprising steps as follows:

[0065] (1) Add phosphate rock powder and excess phosphoric acid into the extraction tank. The solid-to-liquid mass ratio of phosphate rock powder and phosphoric acid is 1:20, and the concentration of phosphoric acid is 24wt%. Under the condition of constant stirring, after the extraction reaction is complete...

Embodiment 3

[0074] Raw material 1: Phosphate rock, collection location: Kailin, Guizhou;

[0075] Raw material 2: magnesium citrate, commercially available;

[0076] Raw material 3: aluminum sulfate, commercially available;

[0077] Raw material 4: sulfuric acid, concentration is 97%, commercially available;

[0078] The sulfuric acid solutions used in the examples are obtained by diluting concentrated sulfuric acid with a concentration of 97 wt%, and carried out in a sulfuric acid dilution tank.

[0079] A method for producing wet-process phosphoric acid byproduct α hemihydrate gypsum whiskers and high-purity and high whiteness α hemihydrate gypsum whiskers, comprising steps as follows:

[0080] (1) Add phosphate rock powder and excess phosphoric acid into the extraction tank. The solid-liquid mass ratio of phosphate rock powder and phosphoric acid is 1:22, and the concentration of phosphoric acid is 25wt%. Under the condition of constant stirring, after the extraction reaction is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com