Micro-fluidic chip achieving multi-index detection

A microfluidic chip, multi-index technology, applied in laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve the problem of unfavorable detection reactions, accurate control of detection results, accurate analysis of detection results, cross-contamination of reaction reagents, and sample volume. problems such as differences, to avoid reagent contamination and mutual interference, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Microfluidic chip structure

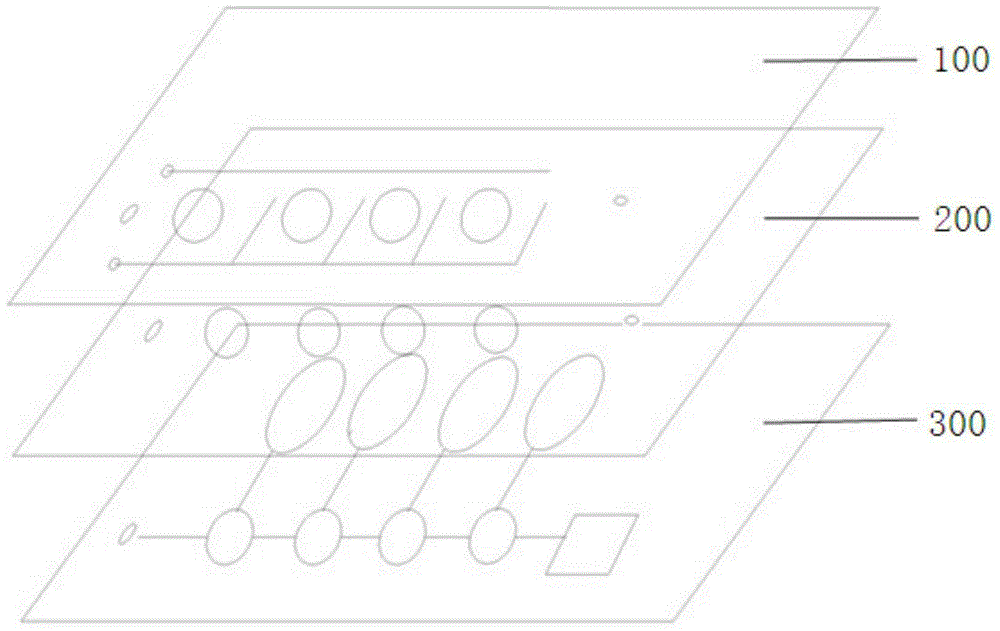

[0029] Such as figure 1 , 2 , 3, 4, and 5: A microfluidic chip for the detection of multiple biochemical indicators, which is formed by bonding and sealing chip materials with integrated microvalves, including a gas control channel layer 100, organic polymer The film 200, the microfluidic channel layer 300, in which:

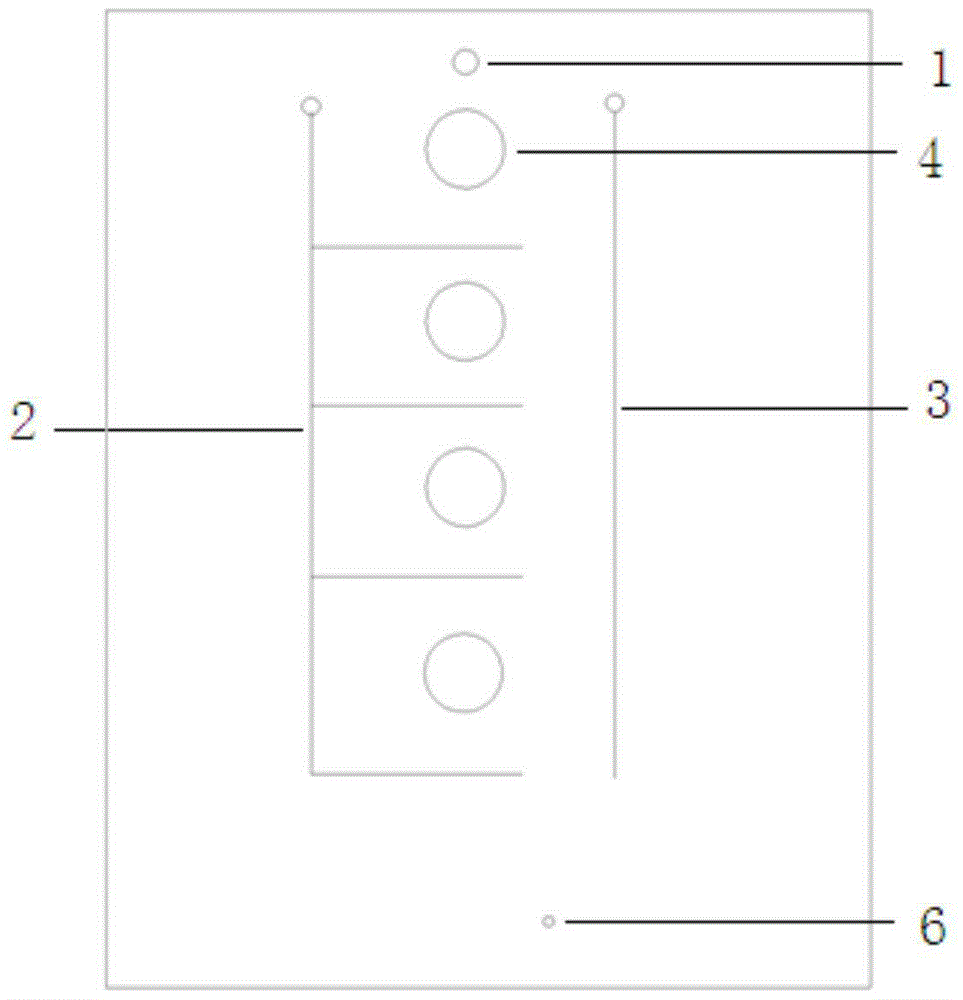

[0030] The gas control channel layer 100 is provided with a sample injection hole 1, a gas outlet 6, two pneumatic microvalves 2, 3, and the upper part of a plurality of serial sample reservoirs 4, and the upper half of the sample reservoir 4 One side is elastic film and exposed to the air;

[0031] The microfluidic channel layer 300 includes a liquid channel 7 connecting the sample inlet and each sample reservoir, a liquid channel 8 connecting each sample reservoir with the corresponding reaction cell, the lower half of the sample reservoir, and the sample injection channel The sample buffer tank 5 and the reaction ...

Embodiment 2

[0038] Embodiment 2: Microfluidic chip workflow

[0039] Step 1: When adding samples, the microvalve 2 is opened, the microvalve 3 is closed, pressurized gas is introduced into the microvalve gas path 13 through the valve seat 12, and the liquid channel of the reservoir toward the reaction tank is closed, and the sample is injected from The hole 1 is injected, the sample flows through the liquid channel 7 into each sample reservoir 4, and the excess sample flows into the sample buffer pool 5;

[0040] Step 2: When all the sample reservoirs 4 are full, the microvalve 2 is closed, the microvalve 3 is opened, pressurized gas is introduced into the microvalve gas path 11 through the valve seat 10, and each reservoir 4 is closed and controlled The microvalve for liquid flow in the liquid channel 7 realizes the isolation between the sample reservoirs 4; open the microvalve that controls the liquid channel of each sample reservoir and the corresponding reaction cell, and press the elastic...

Embodiment 3

[0041] Embodiment 3: Manufacturing method of microfluidic chip

[0042] (1) Preparation of mold with microstructure on microfluidic chip

[0043] Computer-aided design software is used to design the microchannel and microstructure of the microfluidic chip, and the chromium plate is used to make the masks of the gas control channel layer and the microfluidic channel layer according to the design drawing.

[0044] Choose silicon wafers for photolithography and etching to make molds. First, clean the silicon wafers, dry the cleaned silicon wafers with nitrogen, and then put them on the homogenizer, take an appropriate amount of photoresist and apply it on the silicon wafer, and start the homogenizer Spin-coating photoresist, place the mask on the silicon wafer coated with photoresist and place it in a photolithography machine for exposure. After developing and post-baking, dry etching is used to obtain an upper gas control channel layer and a lower layer Mold for the microstructure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com