Surface patterning-modified substrate and preparation method therefor

A technology for substrates and substrate surfaces, applied in the field of surface patterned substrates and their preparation, can solve problems such as unstable hydrophilic and hydrophobic properties, cumbersome operation steps, etc., and achieve low cost, stable modification, and low processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

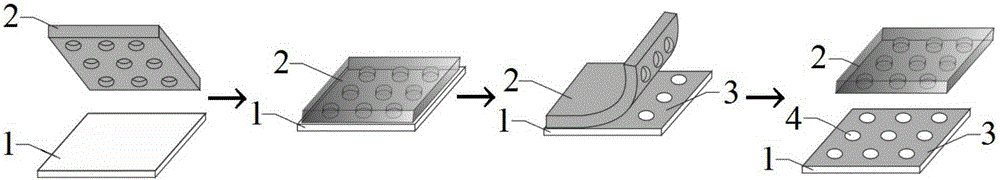

[0044] The invention provides a method for preparing a surface patterned substrate, the specific steps are as follows:

[0045] (1) Design a photolithographic mask according to the morphology of the desired hydrophilic region and hydrophobic region; Similarly, when using a positive mold photoresist, such as SU-8, the shape of the mask is the same as that of the required hydrophilic region; then, use negative mold lithography or positive mold lithography to prepare A PDMS (polydimethylsiloxane) stamp, the PDMS stamp includes a raised portion and a depressed portion, the shape of the raised portion corresponds to a hydrophobic region, and the shape of the depressed portion corresponds to a hydrophilic region;

[0046] (2) Treat the PDMS stamp and the substrate with plasma, so that the PDMS stamp and the substrate surface generate free radicals; wherein, the substrate is a substrate with a smooth surface and a hydrophilic group; the hydrophilic The water group is an alkoxy group, ...

Embodiment 1

[0060] The preparation of embodiment 1 glass substrate

[0061] Step 1: Make the positive mold by soft lithography technology

[0062] Throw the photoresist SU-8 (1070) on the cleaned and dried silicon wafer (700r18s, 2500r60s), and pre-baked to remove the solvent in the SU-8 glue (65°C 15min, 95°C 2hour), so that SU-8 The positive mold is better bonded to the silicon wafer, and then photolithography (3.5mJ / cm 2 ), the mask plate used in lithography is set according to the shape of the positive mold, and the photolithography time is 60s; then it is placed on a hot plate for post-baking (65°C 15min, 95°C 2hour), so that the positive mold and The silicon wafer is more closely bonded, and after being developed by a developer, the film is hardened (135°C) for more than 1 hour to achieve the effect of close adhesion between SU-8 and the silicon wafer, and the SU-8 anode with microstructure can be obtained. mold, and its height was measured to be about 20 μm.

[0063] Step 2: Pre...

Embodiment 2

[0069] Repeat Example 1 with the same steps described above, the difference is that in step 1, AZ-50 is used as the photoresist as AZ50, the mask plate is set according to the concave part of the PDMS stamp, and PDMS is prepared using the corresponding preparation process of AZ-50 seal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com