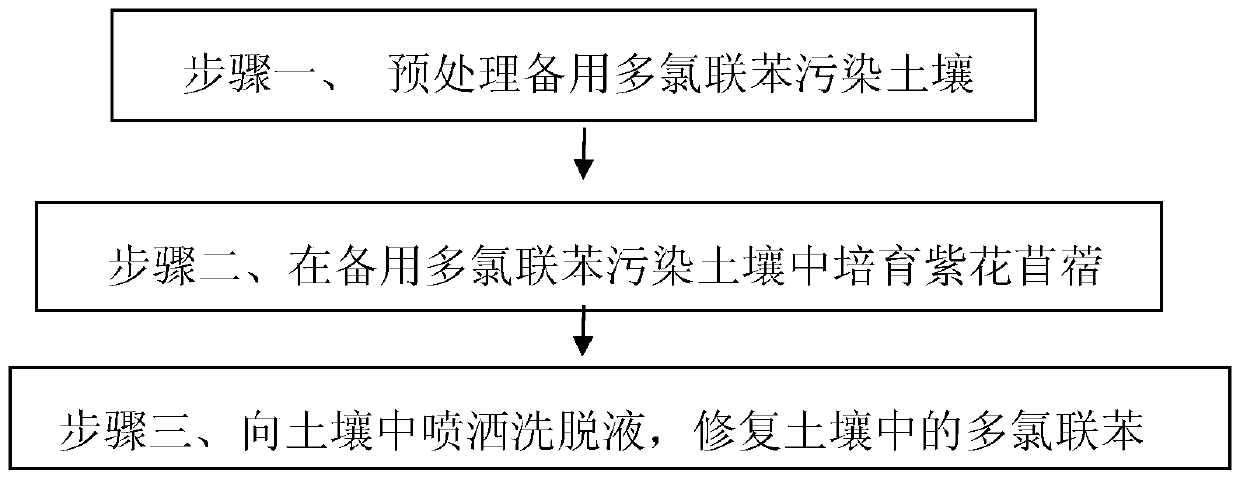

A chemical elution-phytocombined method for remediating PCB-contaminated soil

A polychlorinated biphenyl and contaminated soil technology, applied in the field of contaminated soil remediation, can solve the problems of limited phytoremediation efficiency, low bioavailability, long remediation period, etc., achieve a wide range of soil types, reduce the risk of secondary pollution, and ecological less toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] After PCB pollution concentration is 2.5mg / kg polluted soil 1kg (dry soil) passes through 60 mesh sieves, regulates soil water content to be 40% of field water holding capacity, then the alfalfa seeds of vernalization, dew are evenly sown in In the soil, the alfalfa plants were grown for two weeks and then the seedlings were thinned out. Polysorbate-80 (Tween80) and ethyl lactate were used to prepare the eluent according to the mass ratio of 2.5:1, that is, the concentrations of Tween80 and ethyl lactate were 250mg / L and 100mg respectively / L. After the alfalfa plants grow for two weeks, apply 200ml of eluent to the soil every 5 days by spraying, strictly control the water content of the soil, and avoid the occurrence of infiltration. 80% relative humidity, daytime) / 18±1°C (no light, 80% relative humidity, night) conditions. The test of cultivating alfalfa continued for 90 days, and samples were taken at 30 days, 60 days and 90 days respectively, and the concentration ...

Embodiment 2

[0036]After 1 kg of contaminated soil (dry soil) with a concentration of PCB pollution of 10 mg / kg passes through a 60-mesh sieve, the soil water content is adjusted to 60% of the field water holding capacity, and then the germination and white alfalfa seeds are evenly sown on the soil In the method, the alfalfa plants were grown for two weeks and then the seedlings were thinned out. Tween80 and ethyl lactate were used to prepare the eluent at a mass ratio of 5:1, that is, the concentrations of Tween80 and ethyl lactate were 500 mg / L and 100 mg / L, respectively. After the alfalfa plants grow for two weeks, apply 200ml of eluent to the soil every 8 days by spraying, strictly control the soil water content, and avoid the occurrence of infiltration. 80% relative humidity, daytime) / 18±1°C (no light, 80% relative humidity, night) conditions. The test of cultivating alfalfa continued for 90 days, and samples were taken at 30 days, 60 days and 90 days respectively, and the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com