Method for degrading quinclorac organic pollutant based on catalysis of persulfate through load-type activated carbon

A technology of quinclorac and organic pollutants, applied in water pollutants, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficulty in strain screening, long degradation period, etc. The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

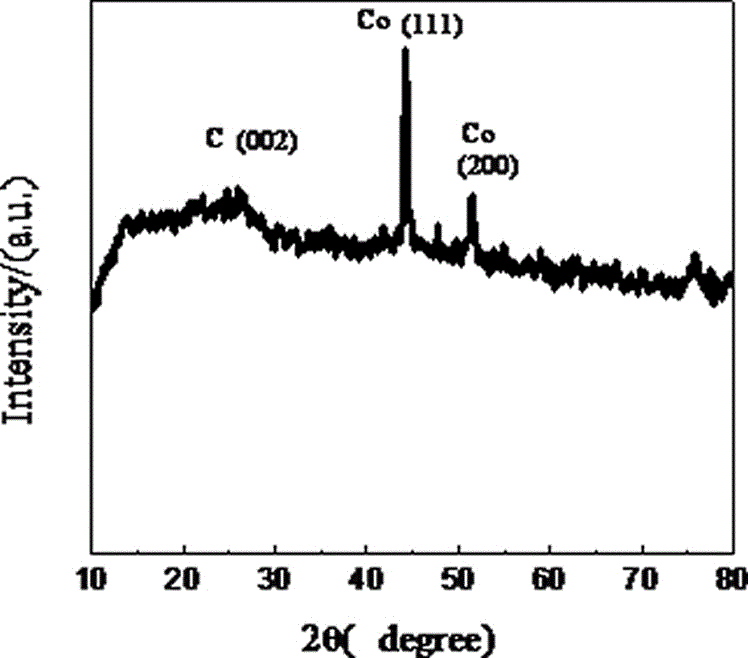

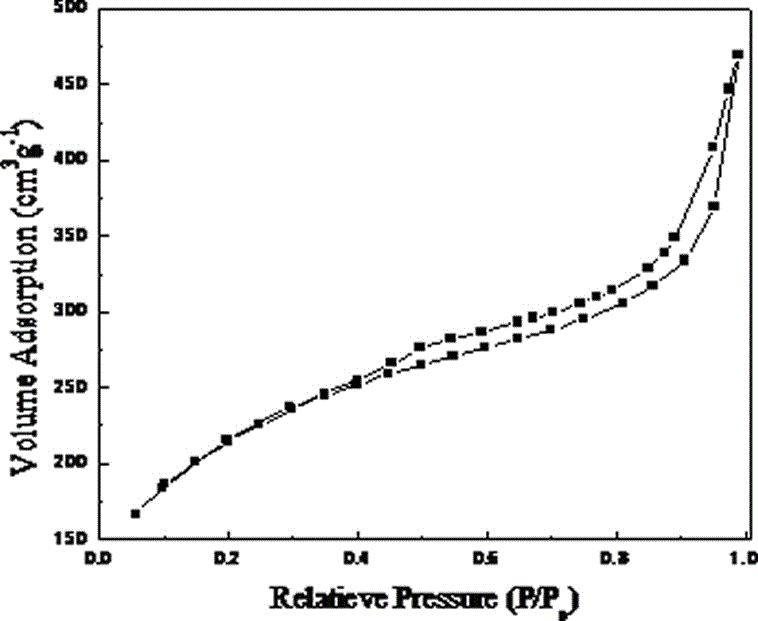

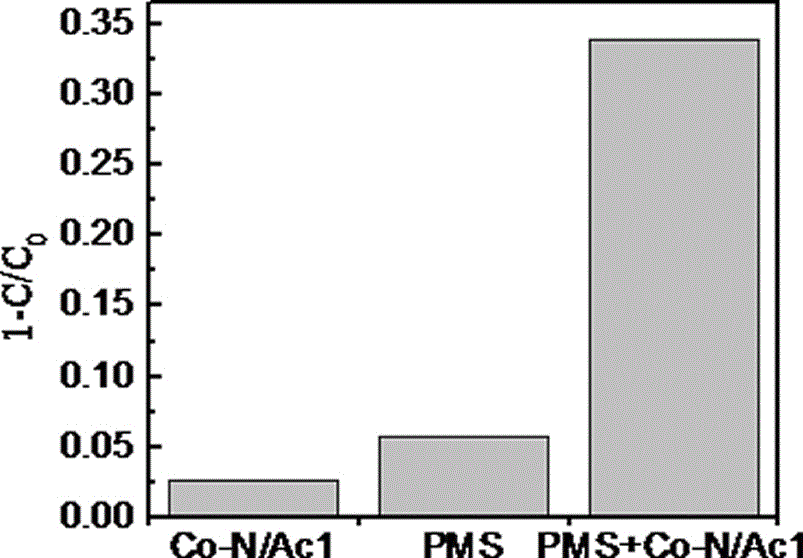

[0026] Preparation of catalyst nitrogen, cobalt co-doped activated carbon: Take 4g flake dry KOH and grind it into powder with agate mortar. Take 8g of disodium ethylenediaminetetraacetic acid (EDTA) and put it into a mortar and grind it with KOH powder evenly, then add 0.90g of cobalt nitrate hexahydrate and grind it evenly, then fill it into 4 magnetic boats (dimensions: length×width×height) ×Thickness=60mm×30mm×15mm×2mm). Vacuum calcined at 600°C for 2h in a tube furnace. After natural cooling to room temperature, samples were washed. First put the sample into a 100mL beaker, add 50-80mL deionized water to ultrasonically clean it for 10min, then suction filter, continue to wash repeatedly with deionized water until the filtrate is clear. Finally, it was washed twice with ethanol, dried in vacuum at 80°C for 24 hours, and then ground and sieved to obtain nitrogen and cobalt co-doped activated carbon (marked as Co-N / Ac1). The catalyst has a specific surface area of 734m2...

Embodiment 2

[0029] Preparation of catalyst nitrogen, cobalt co-doped activated carbon: Take 4g flake dry KOH and grind it into powder with agate mortar. Take 8g of disodium ethylenediaminetetraacetic acid (EDTA) and put it into a mortar and grind it with KOH powder evenly, then add 0.90g of cobalt nitrate hexahydrate and grind it evenly, then transfer it to a rectangular quartz boat (dimensions: length × width × height × thickness =400mm×40mm×18mm×2mm). Vacuum calcined at 600°C for 2h in a tube furnace. After natural cooling to room temperature, samples were washed. First put the sample into a 100mL beaker, add 50-80mL deionized water to ultrasonically clean it for 10min, then suction filter, continue to wash repeatedly with deionized water until the filtrate is clear. Finally, it was washed twice with ethanol, dried in vacuum at 80°C for 24 hours, and then ground and sieved to obtain nitrogen and cobalt co-doped activated carbon (marked as Co-N / Ac2).

[0030] Degradation of quinclorac...

Embodiment 3

[0032] co 2+ Catalytic persulfate degradation of quinclorac organic pollutants: prepare 1.0g / L quinclorac stock solution, 1.0mmol / LCo(NO 3 ) 2 stock solution and 100mmol / L potassium persulfate (PMS) stock solution. Then pipette a certain volume of Co(NO 3 ) 2 Stock solution and PMS stock solution into the reaction vessel, so that the concentration of the two is 0.04mmol / L and 4mmol / L respectively (that is, the molar concentration ratio of the two is 1:100), and then add the quinclorac solution to the reactor Make its initial concentration 10mg / L, after shaking at room temperature for 24h, the degradation rate of quinclorac is 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com