Thermo-sensitive polymer carrier and preparation method and application thereof

A temperature-sensitive polymer and carrier technology, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of low film stability and bioavailability, and achieve simple process, cheap raw materials, strong resistance The effect of protein adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

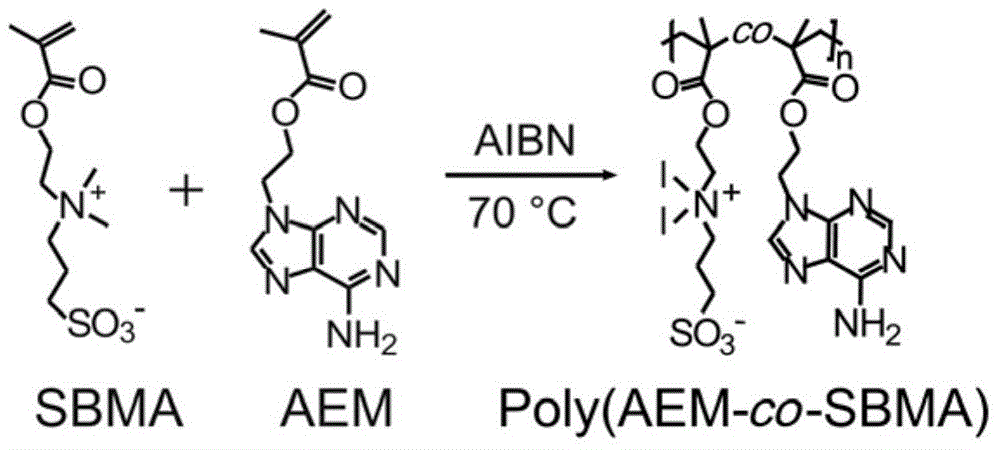

[0031] The preparation method of the above-mentioned temperature-sensitive polymer carrier comprises the following steps: (a) dissolving monomer A, monomer B and initiator in the first solvent, stirring and reacting at 65-75°C under anaerobic conditions After 70-74 hours, a sulfobetaine-adenine solution is obtained; (b) pour the sulfobetaine-adenine solution into a precipitant, filter and dry. The first solvent is preferably dimethyl sulfoxide, the precipitating agent is preferably acetone, and the initiator can be selected from existing ones, and its amount is determined according to the total amount of monomer A and monomer B.

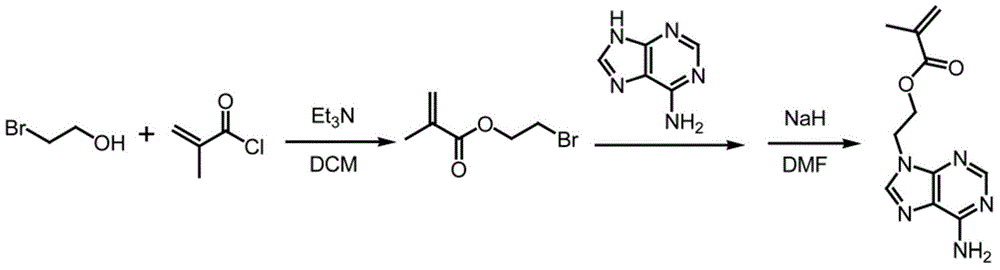

[0032] The preparation method of the monomer B comprises the following steps: (S1) dissolving 2-bromoethanol, methacryloyl chloride and triethylamine in dichloromethane, stirring and reacting for 17.5-18.5 hours to obtain a mixed solution; (S2) filtering Described mixed solution, after adding ice-water mixing in filtrate, leave standstill sealing lay...

Embodiment 1

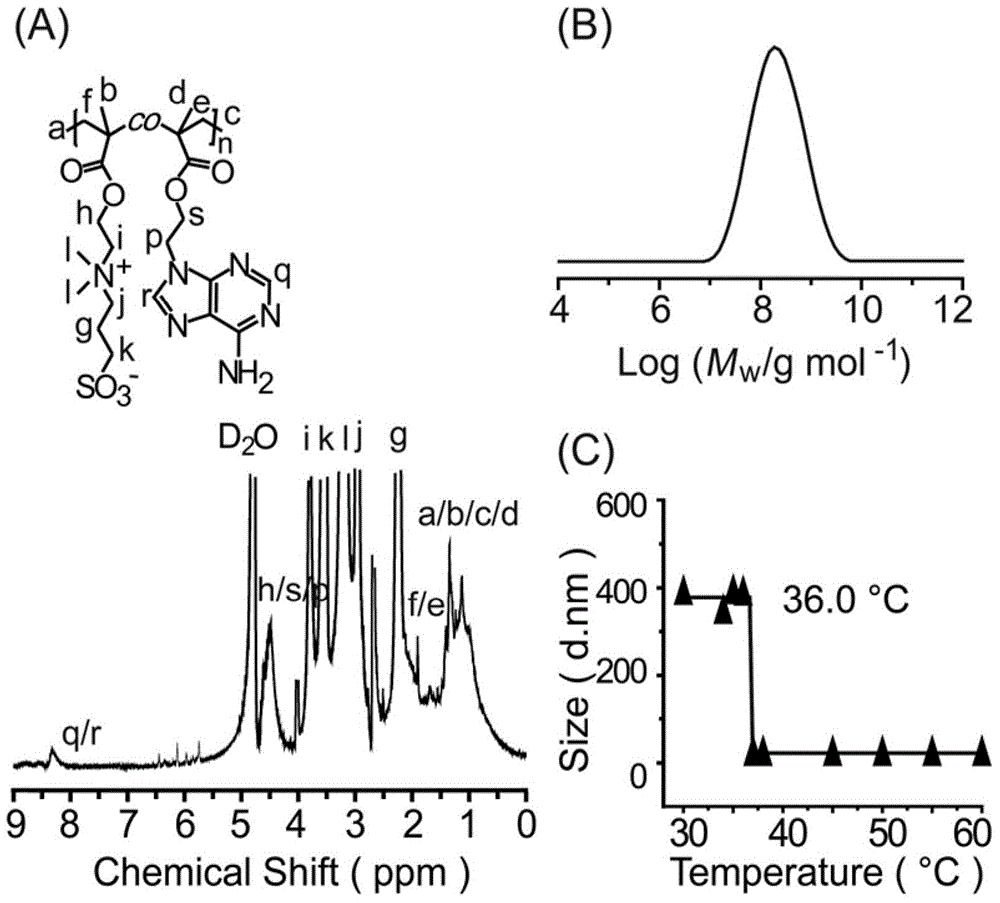

[0036] This embodiment provides a thermosensitive polymer carrier, which is prepared as figure 1 As shown, specifically: according to the molar ratio of 1:1, 0.35mmol SBMA (structural formula as figure 1 Shown, American Sigma Company, 97%), 0.35mmolAEM (structural formula such as figure 1As shown, Shanghai Bailingwei Company, 98%), 0.0055g AIBN (Sinopharm Chemical Reagent Co., Ltd., chemically pure) were added to 4.0mL of anhydrous DMSO (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99.0%), at room temperature Stir until the solute is completely dissolved to obtain a mixed solution; put the above mixed solution in an ampule bottle, pass through argon to remove dissolved oxygen, then seal it and put it in an oil bath at 70°C, and react for 72 hours; the product after the reaction Precipitate three times with acetone and dry under vacuum to obtain a polymer, abbreviated as P(SBMA-co-AEM), which is characterized as image 3 and Figure 4 as shown, image 3 (A) is 1H-NMR (400...

Embodiment 2

[0057] This example provides a temperature-sensitive polymer carrier, the preparation method of which is basically the same as that in Example 1, except that the molar ratio of monomer A to monomer B is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com