Acid-salt solid-phase-free medium-density workover fluid and preparation method thereof

A preparation method, solid phase-free technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of scaling damage, high pressure of Banqiao water injection well, difficult operation, etc. Good shale expansion and the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a beaker with a volume of 500 ml, measure 40.2 parts of clear water with a graduated cylinder as the base liquid, first add 0.175 parts of sodium dodecylbenzenesulfonate, and stir at a high speed for 5 minutes, for example, at a rate of 3000 rpm; Slowly and evenly add 0.4 parts of corrosion inhibitor, and stir for 5 minutes at high speed, for example, at a rate of 3000 rpm; finally add 58 parts of sodium dihydrogen phosphate, and mix well to prepare the finished product.

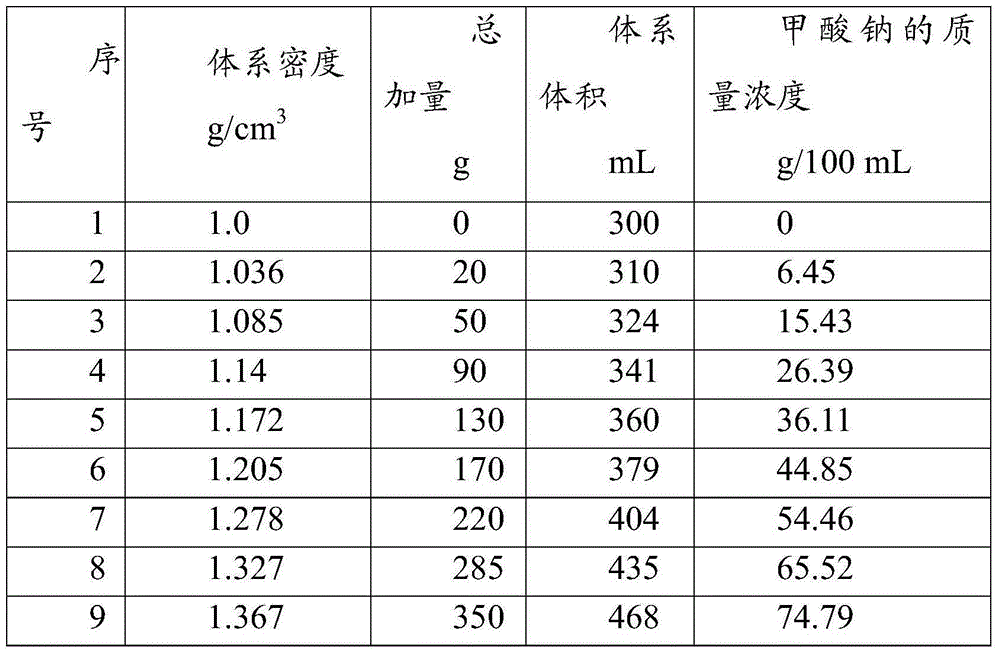

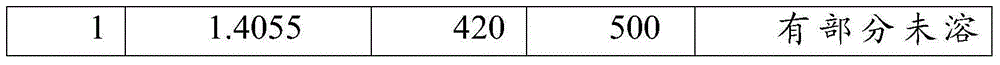

[0023] The main component of the low-cost acid salt-free medium-density workover fluid of the present invention is sodium dihydrogen phosphate, which has good solubility and a density of up to 1.40g / cm 3 See Table 1; it has good stability, and its temperature resistance can reach 160°C, see Table 2; it does not contain solid phase components, does not contain divalent ions such as calcium and magnesium, and has strong characteristics of inhibiting shale expansion. The reduction rate is greater than...

Embodiment 2

[0034] In a beaker with a volume of 500 ml, measure 42 parts of clear water with a graduated cylinder as the base liquid, first add 0.05 part of sodium dodecylbenzenesulfonate, stir at high speed for 5 minutes, for example, stir at a rate of 3000 rpm; Slowly and evenly add 0.5 parts of corrosion inhibitor, stir at high speed for 5 minutes, for example, at a rate of 3000 rpm; finally add 60.2 parts of sodium dihydrogen phosphate, and mix well to prepare the finished product.

[0035] The density of the low-cost acid salt-free medium-density workover fluid of the present invention can reach 1.39g / cm 3 , with formate-free solid-phase workover fluid good reservoir protection performance, compared with the same density formate system, the cost is reduced by more than 20%.

[0036] Table 5 Cost comparison of low-cost acid salt of the present invention without solid phase medium density workover fluid

[0037]

Embodiment 3

[0039] In a beaker with a volume of 500 ml, measure 39 parts of clear water with a graduated cylinder as the base liquid, first add 0.3 part of sodium dodecylbenzenesulfonate, stir at high speed for 5 minutes, for example, stir at a speed of 3000 rpm; Then slowly and evenly add 0.3 parts of corrosion inhibitor, stir at high speed for 5 minutes, for example, stir at a rate of 3000 rpm; finally add 56 parts of sodium dihydrogen phosphate, and mix well to prepare the finished product with a density of 1.41g / cm 3 , which will not be repeated here.

[0040] Compared with liquid calcium, brine, mud, and formate salt solid-free high-density workover fluids in the prior art, the low-cost acid salt solid-free medium-density workover fluid technology provided by the embodiment of the present invention has the following advantages :

[0041] 1. The performance of the low-cost acid salt-free medium-density workover fluid in the present invention is stable, and the density can reach 1.40g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com