Degradable cigarette filter tip filament bundle and preparation method thereof

A filter and tow technology, which is applied in the manufacture and application of e-liquid filter elements, rayon, etc., can solve the problems of easy hydrolysis, poor heat resistance, and effect effects, and achieve increased heat resistance, good adhesion, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

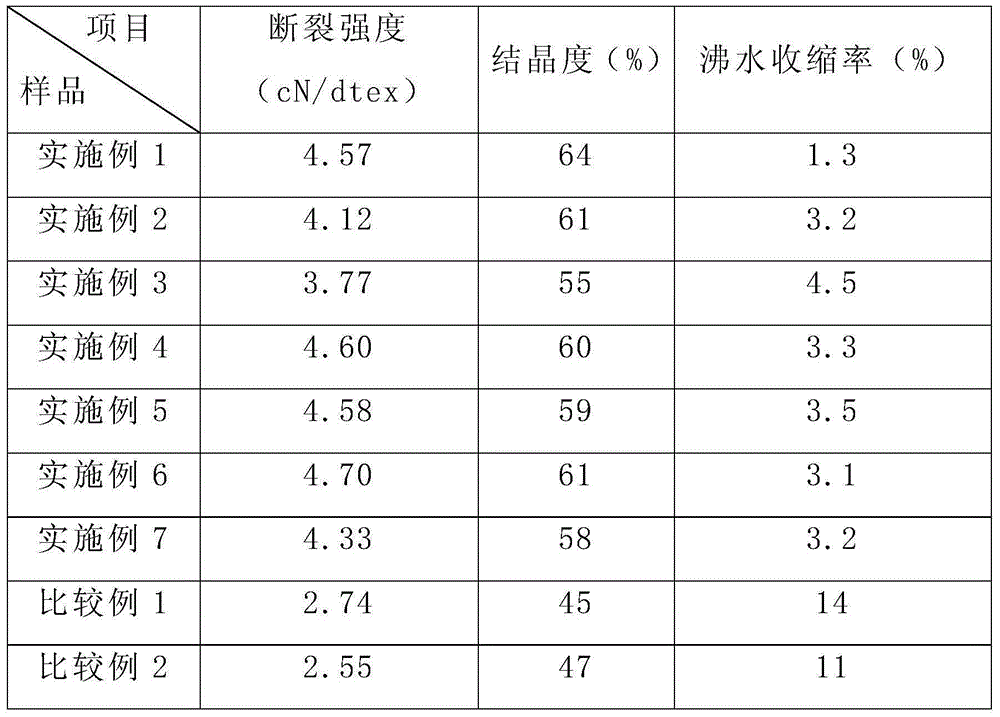

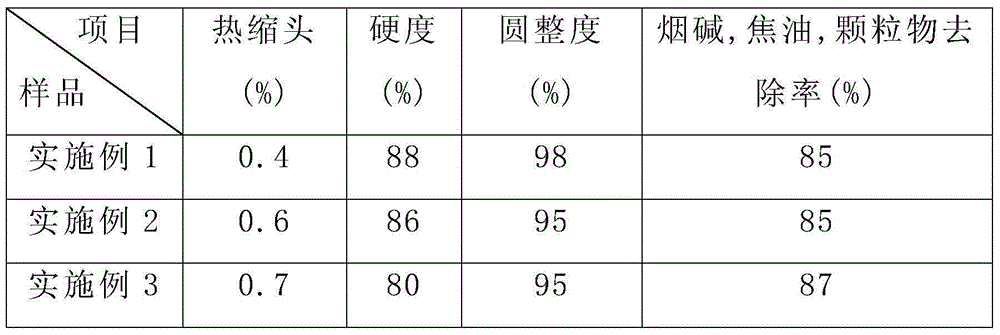

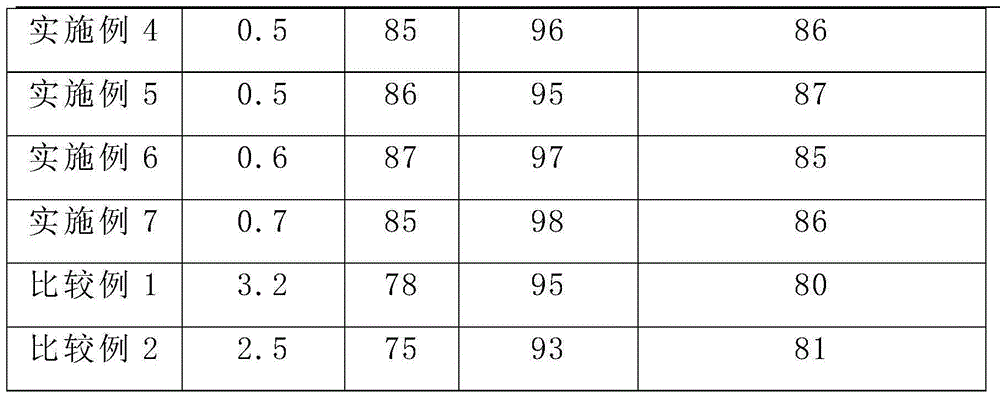

Examples

Embodiment 1

[0027] Synthesis of polylactic acid copolymer:

[0028] Under the protection of nitrogen, add 83kg of terephthalic acid, 73kg of adipic acid, 90kg of butanediol and 0.1kg of tetrabutyl titanate into the reaction kettle with mechanical stirring, raise the temperature to 140°C under normal pressure and control the temperature Carry out the esterification reaction, and completely distill off the water; then raise the temperature to 210°C, and gradually reduce the pressure to 100Pa vacuum degree, and carry out the polycondensation reaction. After stirring for 2 hours, the corresponding intermediate product is obtained. After the reaction, reduce the temperature to At 120°C, add 700kg of dried L-lactide and 0.7kg of stannous octoate, react for 12 hours, protect with nitrogen, and then extrude and granulate to obtain poly-L-lactic acid block copolymer, that is, polylactic acid copolymer things.

Embodiment 2

[0030] The degradable cigarette filter tow of the present embodiment is mainly made of the following raw materials in parts by weight:

[0031] Poly L-lactic acid: 94; the number average molecular weight of the poly L-lactic acid is 200000, and the distribution width is 2.0;

[0032] Poly-D-lactic acid: 5.0; the number-average molecular weight of the poly-D-lactic acid is 180,000, and the distribution width is 2.0;

[0033] Polylactic acid copolymer: 1.0; the polylactic acid copolymer is formed by copolymerization of polylactic acid and polyadipic acid-terephthalic acid-butylene glycol, which can be prepared by the method of the above-mentioned embodiment 1, and the polylactic acid copolymer The mass ratio of polylactic acid to polyadipic acid-terephthalic acid-butylene glycol in the copolymer is 3:1;

[0035] The preparation method of the above-mentioned degradable cigarette filter tow is as follows:

[0036] According to the weight ratio of th...

Embodiment 3

[0038] The degradable cigarette filter tow of the present embodiment is mainly made of the following raw materials in parts by weight:

[0039] Poly L-lactic acid: 84; the number average molecular weight of the poly L-lactic acid is 120,000, the distribution width is 1.5, and the optical purity of L-lactic acid in the poly L-lactic acid is ≥98%;

[0040] Poly-D-lactic acid: 1.0; the number-average molecular weight of the poly-D-lactic acid is 100,000, the distribution width is 1.8, and the optical purity of D-lactic acid in the poly-D-lactic acid is ≥98%;

[0041] Polylactic acid copolymer: 15; the polylactic acid copolymer is formed by copolymerization of polylactic acid and polyadipic acid-terephthalic acid-butylene glycol, which can be prepared by the method of the above-mentioned embodiment 1, and the polylactic acid copolymer The mass ratio of polylactic acid to polyadipic acid-terephthalic acid-butylene glycol in the copolymer is 1:3; and the number average molecular wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com