Forward osmosis membrane based on interface hydrophilic modification and preparation method of forward osmosis membrane

A technology of forward osmosis membrane and hydrophilic modification, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., to achieve the effects of reducing tortuosity, reducing osmotic resistance, and reducing the ratio of salt water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

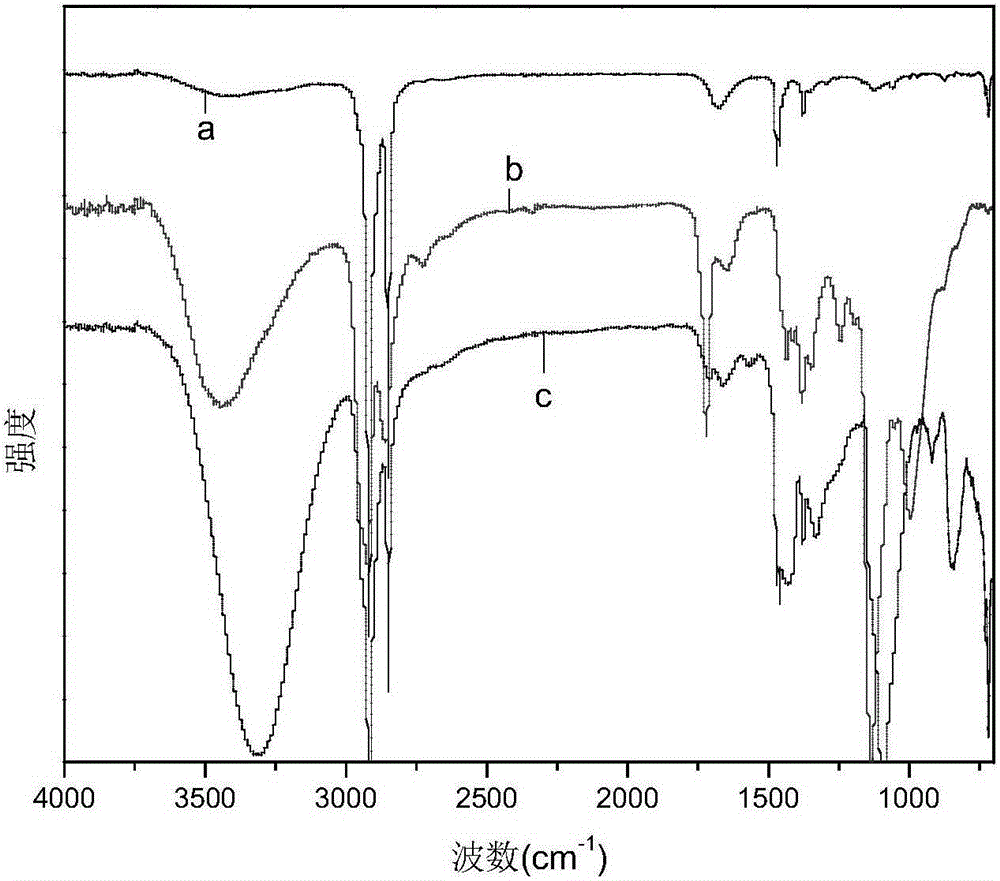

[0053] (1) Soak polypropylene (PP) non-woven support material (basis weight 52 g / m2, thickness 85 microns) with acetone to remove impurities adsorbed on the surface, and then dry it for later use;

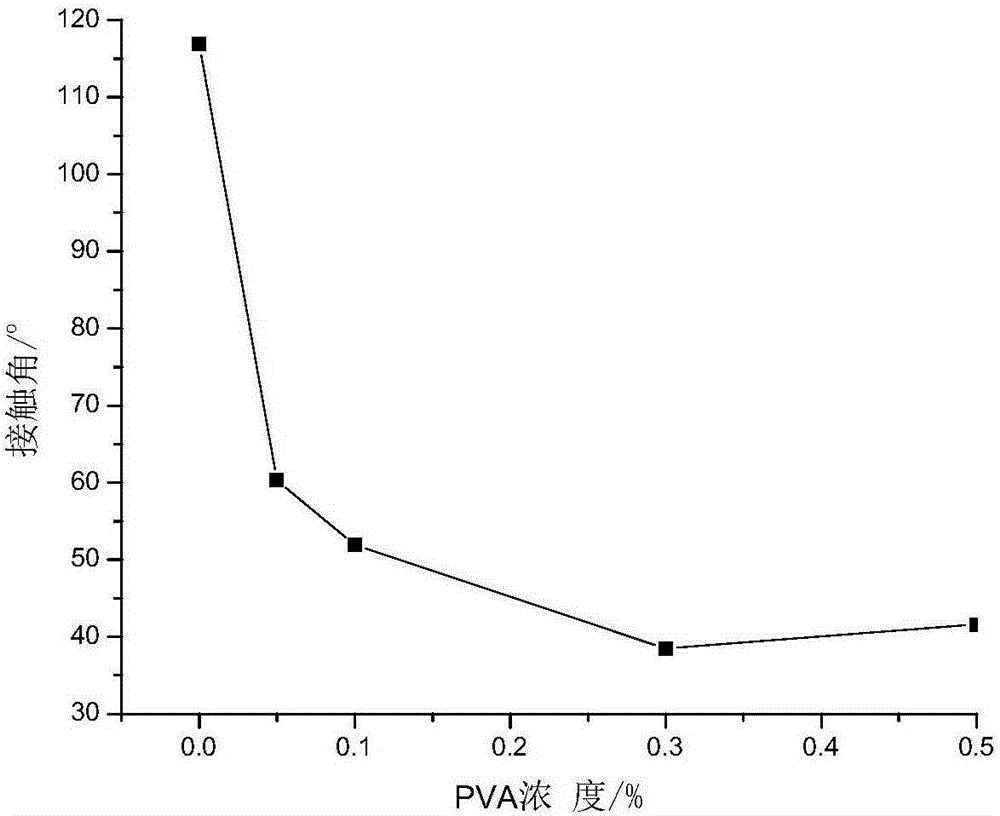

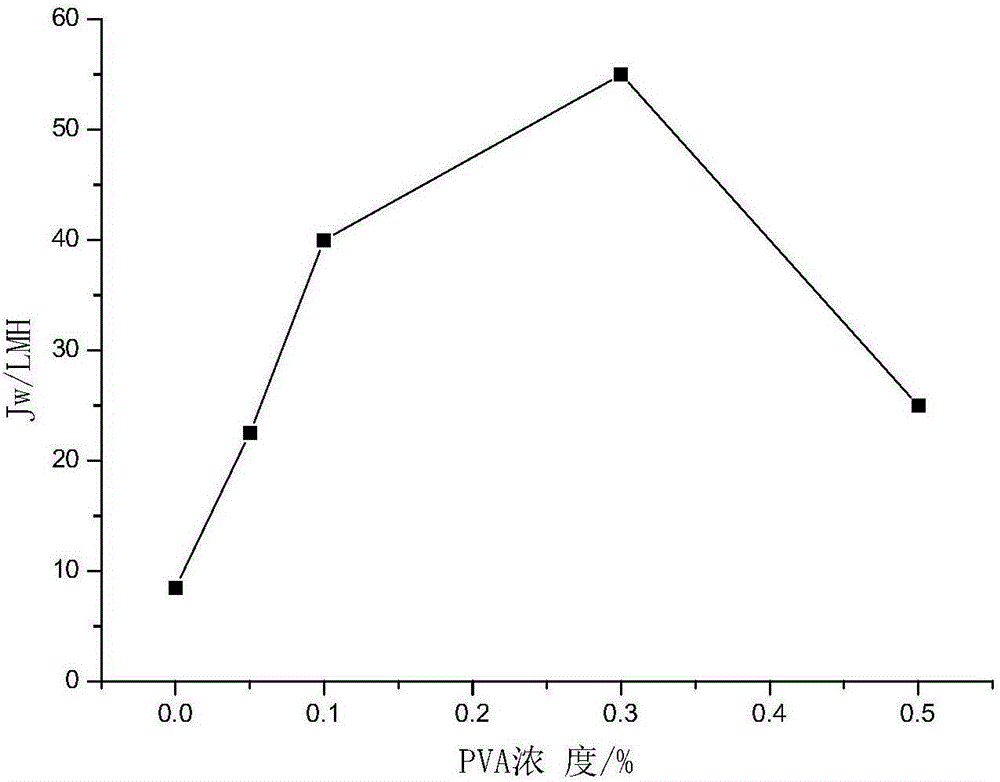

[0054] (2) Immerse the treated non-woven support material in an aqueous solution of hydrophilic polymer polyvinyl alcohol (PVA) with a mass percent concentration of 0.05%, 0.1%, 0.3%, and 0.5%, respectively, and then remove the excess solution, Dry and reserve;

[0055] (3) Add 13.1% (V%) cellulose triacetate (CTA) to 52.4% (V%) 1,4-dioxane, 19.7% (V%) acetone, 8.2% (V%) methanol In a mixed solvent of 6.6% (V%) lactic acid, heat and stir at 40°C to dissolve, and let it stand for more than 24 hours to completely defoam;

[0056] (4) Pour the above-mentioned casting solution on the dried support material, scrape the film with a scraper with a gap of 150 microns, volatilize in the air for 30 seconds at room temperature and 90% relative humidity, and then immerse it in deionized water...

Embodiment 5

[0060] (1) Soak the polyester (PET) non-woven support material (basis weight 55 g / m2, thickness 66 microns) with acetone to remove impurities adsorbed on the surface, and then dry it for later use;

[0061] (2) Immerse the treated non-woven support material in an aqueous solution of hydrophilic polymer polyvinyl alcohol (PVA) with a concentration of 0.3% by mass, then remove the excess solution, and dry it for later use;

[0062] (3) Add 10.1% (V%) cellulose triacetate (CTA) to 54.4% (V%) 1,4-dioxane, 20.7% (V%) acetone, 8.2% (V%) methanol In a mixed solvent of 6.6% (V%) lactic acid, heat and stir at 40°C to dissolve, and let it stand for more than 24 hours to completely defoam;

[0063] (4) Pour the above-mentioned casting solution on the dried support material, scrape the film with a scraper with a gap of 160 microns, volatilize in the air for 30 seconds at room temperature and 80% relative humidity, and then immerse it in deionized water to make it dry. Gel to obtain nasce...

Embodiment 6

[0067] (1) Soak the polyester (PET) non-woven support material (basis weight 55 g / m2, thickness 66 microns) with acetone to remove impurities adsorbed on the surface, and then dry it for later use;

[0068] (2) Immerse the treated non-woven support material in a mixed solution of hydrophilic polymer polyvinyl alcohol (PVA) and cross-linking agent with a concentration of 0.3% by mass, react at 50°C for 1 hour, and then remove The excess solution was dried for later use; the crosslinking solution contained 10vol.% sulfuric acid, 10vol.% acetic acid, 10vol.% methanol, and 2wt.% glutaraldehyde (GA) at a volume ratio of 1:2:3;

[0069] (3) Add 10.1% (V%) cellulose triacetate (CTA) to 54.4% (V%) 1,4-dioxane, 20.7% (V%) acetone, 8.2% (V%) methanol In a mixed solvent of 6.6% (V%) lactic acid, heat and stir at 40°C to dissolve, and let it stand for more than 24 hours to completely defoam;

[0070] (4) Pour the above-mentioned casting solution on the dried support material, scrape the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com