Modified walnut shell active carbon adsorbent and preparation method thereof

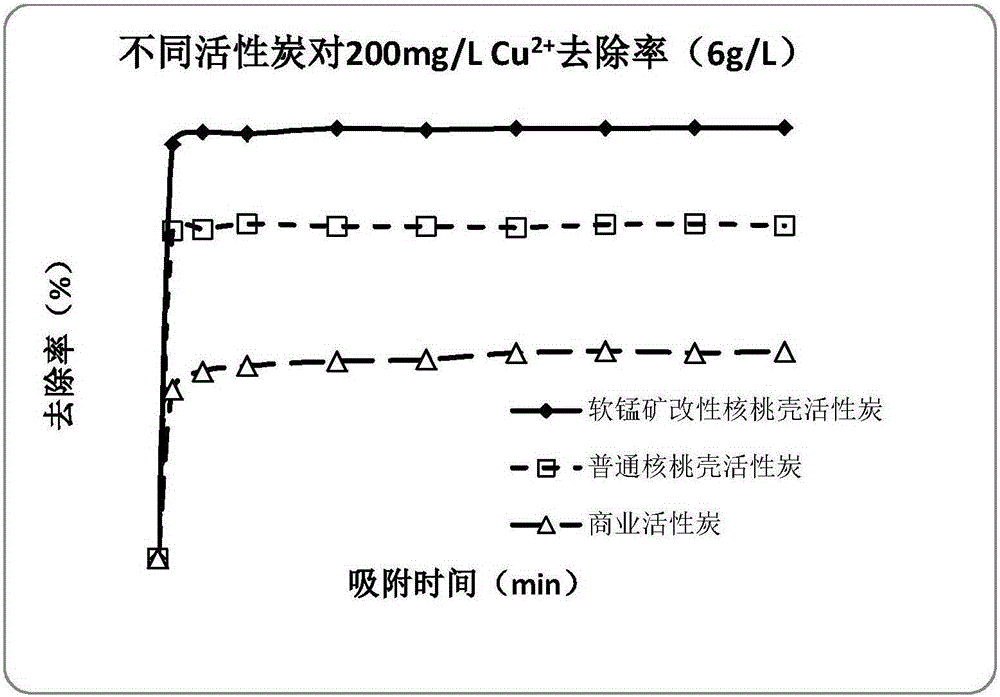

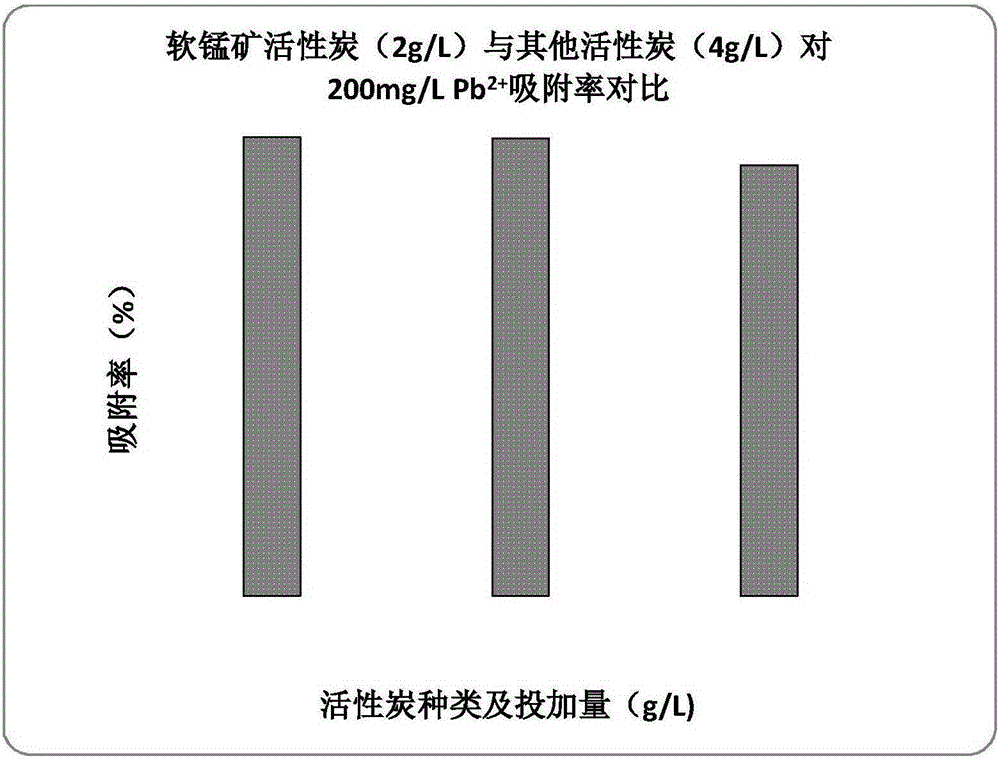

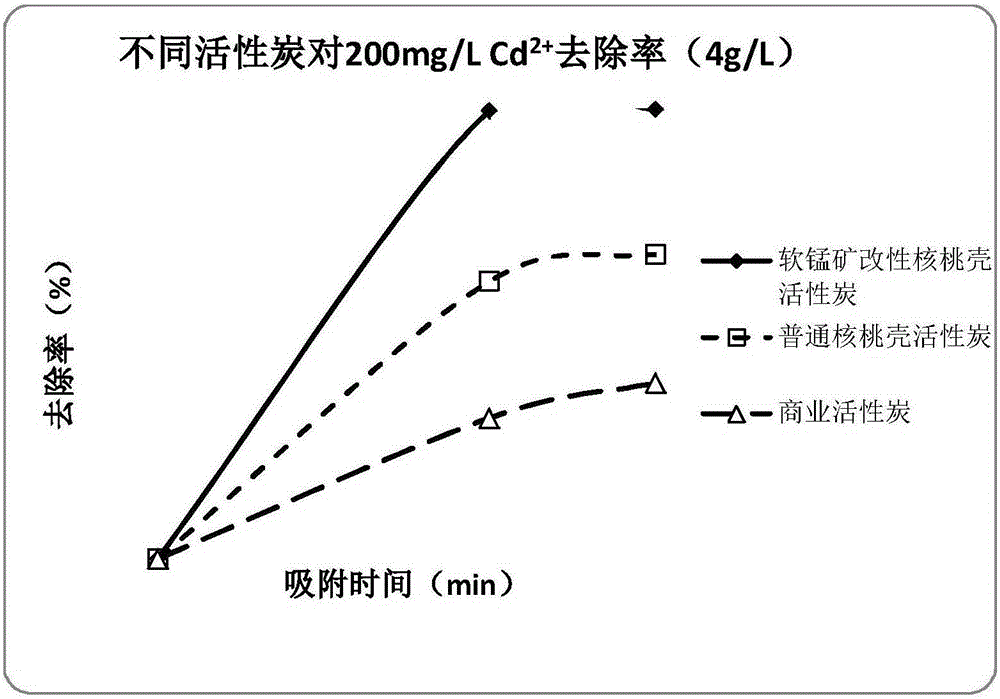

An activated carbon adsorption, walnut shell technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of large optimal adsorption dosage, unstable adsorption performance of adsorbents, harsh experimental conditions, etc. To achieve the effect of strong market competitiveness and promotion value, good ability to remove heavy metal ions, and easier control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] The walnut shell powder sieved through 150 mesh is dried for later use, then the concentrated phosphoric acid solution is diluted with water to form a phosphoric acid solution with a mass fraction of 25%, and then the dried pyrolusite powder is added to the walnut shell powder according to 0.1% of the total mass Mix evenly, and add 20mL of prepared phosphoric acid solution to immerse. After fully stirring, place it in an ultrasonic cleaner for 2 hours, take it out and place it in an oven for activation for 18 hours. The mixture was then fired at 450 °C for 1 h in a tube furnace. After cooling to room temperature, wash repeatedly with hot water until neutral, dry, grind and sieve.

example 2

[0045] The walnut shell powder sieved through 200 mesh is dried for later use, then the concentrated phosphoric acid solution is diluted with water to form a phosphoric acid solution with a mass fraction of 40%, and then the dried pyrolusite powder is added to the walnut shell powder according to 1.0% of the total mass Mix evenly, and add 40mL of prepared phosphoric acid solution to immerse. After fully stirring, place it in an ultrasonic cleaner for 2 hours, take it out and place it in an oven for activation for 24 hours. The mixture was then fired at 550 °C for 1 h in a tube furnace. After cooling to room temperature, wash repeatedly with hot water until neutral, dry, grind and sieve.

example 3

[0047] The walnut shell powder sieved through 300 meshes is dried for later use, then the concentrated phosphoric acid solution is diluted with water to form a phosphoric acid solution with a mass fraction of 30%, and then the dried pyrolusite powder is added to the walnut shell powder according to 2.0% of the total mass Mix evenly, and add 25mL of prepared phosphoric acid solution to immerse. After fully stirring, place it in an ultrasonic cleaner for 3 hours, take it out and place it in an oven for activation for 20 hours. The mixture was then fired at 480 °C for 2 h in a tube furnace. After cooling to room temperature, wash repeatedly with hot water until neutral, dry, grind and sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com