Benzaldehyde Schiff base type aminopyridine acetylated starch and preparation method thereof

A technology of aminopyridine acetyl and Schiff base, which is applied in the field of daily chemicals, and achieves the effects of easy promotion, simple synthesis steps, and improved reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The synthesis route of benzaldehyde Schiff base aminopyridine acetylated starch is as follows.

[0034]

[0035] Wherein R is a halogenated phenyl group, and the average value range of n is 5-12000.

[0036] In this example, the target compound benzaldehyde Schiff base aminopyridine acetylated starch was synthesized according to the above synthetic route.

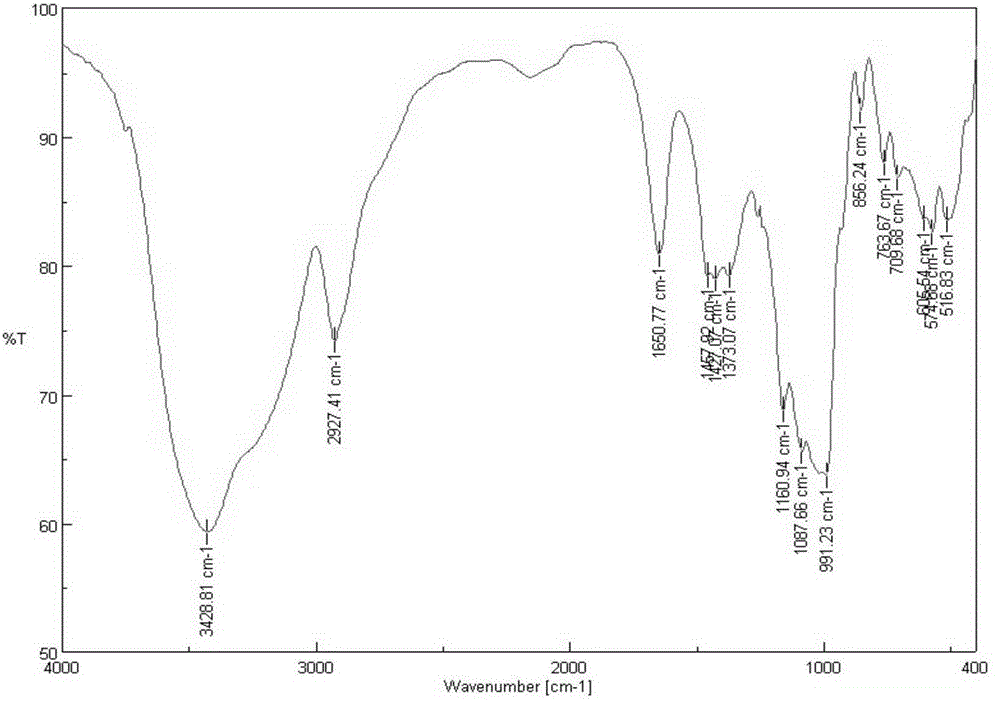

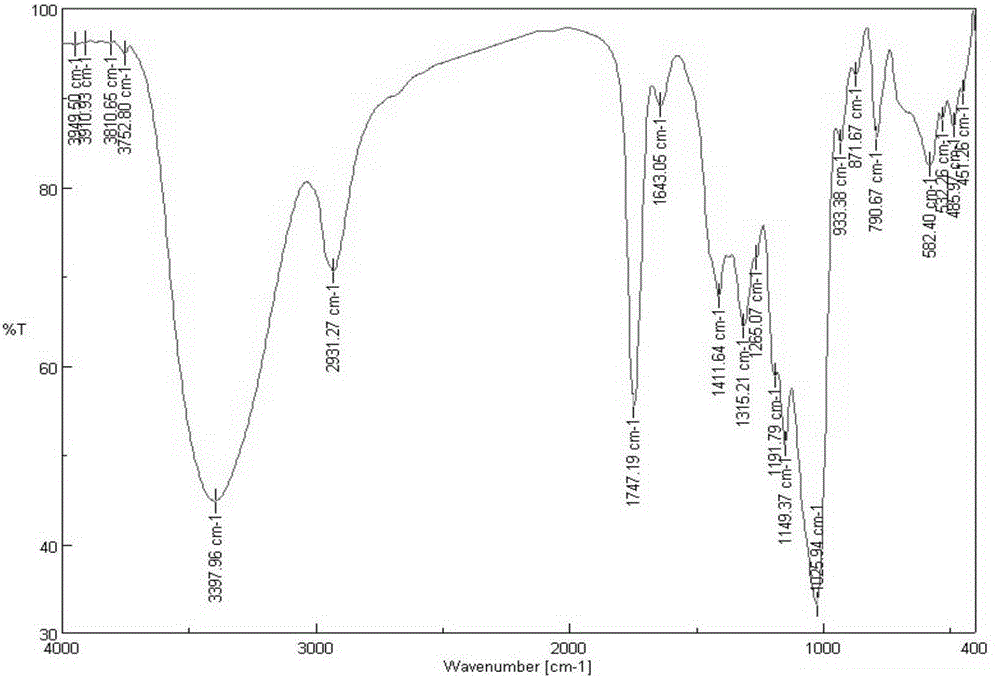

[0037] 1) Preparation of chloroacetyl starch: 1.62g starch (see figure 1 ) into 100mL of distilled water and stirred at room temperature for 20min, after adding 1.51mL of chloroacetyl chloride, reacted at room temperature for 20min, after the reaction was completed, concentrated by rotary evaporation under reduced pressure, precipitated with 50mL of absolute ethanol after cooling, suction filtered, washed, and vacuum frozen After drying, obtain product chloroacetyl starch (see figure 2 ) 1.1g, set aside.

[0038] 2) Preparation of Schiff base: first dissolve 10mmol of 4-fluorobenzaldehyde in 20mL of absolute e...

Embodiment 2

[0041] The difference from Example 1 is:

[0042] 1) Preparation of chloroacetyl starch: 1.62g starch (see figure 1 ) into 80mL of distilled water and stirred at room temperature for 40min, after adding 2.0mL of chloroacetyl chloride, reacted at room temperature for 30min, after the reaction was completed, concentrated by rotary evaporation under reduced pressure, precipitated with 30mL of absolute ethanol after cooling, suction filtered, washed, and vacuum frozen After drying, obtain product chloroacetyl starch (see figure 2 ) 1.3g, for use.

[0043] 2) Preparation of Schiff base: first dissolve 15mmol of 4-chlorobenzaldehyde in 20mL of absolute ethanol, then dissolve 10mmol of 3-aminopyridine in 10mL of absolute ethanol and slowly add it dropwise to the above-mentioned absolute ethanol solution of benzaldehyde , after it is mixed evenly, reflux and stir at 60°C for 8h, then use a rotary evaporator to spin off absolute ethanol, and finally cool, recrystallize, and freeze-dry...

Embodiment 3

[0046] The difference from Example 1 is:

[0047] 1) Preparation of chloroacetyl starch: 1.62g starch (see figure 1 ) into 100mL of distilled water and stirred at room temperature for 20min. After adding 3.02mL of chloroacetyl chloride, react at room temperature for 40min. After drying, obtain product chloroacetyl starch (see figure 2 ) 1.1g, set aside.

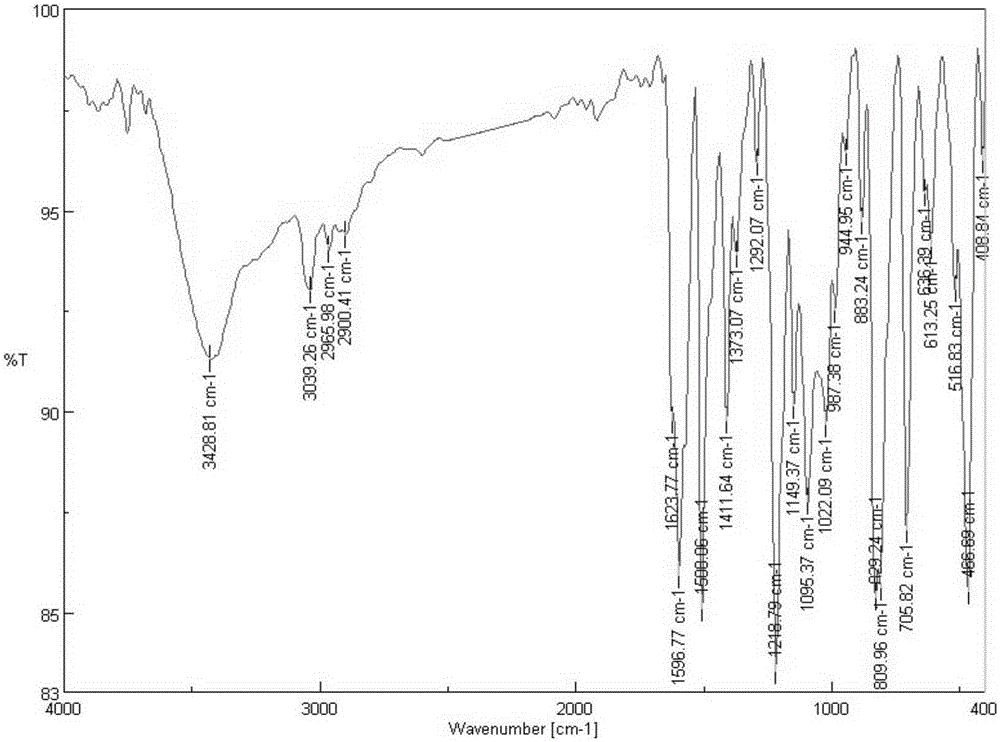

[0048] 2) Preparation of Schiff base: first dissolve 20mmol of 4-bromobenzaldehyde in 20mL of absolute ethanol, then dissolve 15mmol of 3-aminopyridine in 10mL of absolute ethanol and slowly add it dropwise to the above-mentioned absolute ethanol solution of benzaldehyde , after it is mixed evenly, reflux and stir at 50°C for 10h, then use a rotary evaporator to spin off absolute ethanol, and finally cool, recrystallize, and freeze-dry to obtain various Schiff bases (see Figure 5 ).

[0049] 3) 2-[4-(4-bromobenzylideneamino)-pyridinium base]-acetyl starch: 1mmol chloroacetyl starch (see figure 2 ) and 4mmol Schiff bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com