Water and soil conservation type degradable liquid mulching film and preparation and application thereof

A liquid mulch, soluble technology, applied in the field of agricultural and forestry applications, can solve the problems of the action time being restricted by external factors, the soil surface is easily damaged, and difficult to apply on a large scale, so as to inhibit the evaporation of soil moisture, enhance the soil moisture retention capacity, and improve the resistance to soil moisture. The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of high tensile strength mulch film:

[0038] (1) Preparation of mixed aqueous solution of polyvinyl alcohol, wood calcium, and silica sol: add 300kg of water to the reaction kettle, and sequentially add 0.075kg of polyvinyl alcohol, 0.025kg of wood calcium, and 50ml of silica sol (30nm), set at 60r / min at 60°C Stir at constant temperature for 2 h, then cool down to room temperature to obtain a mixed solution.

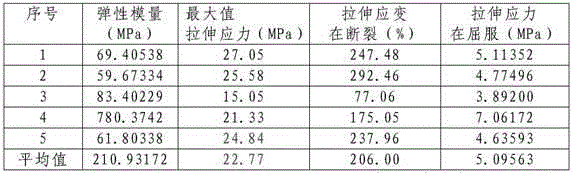

[0039] (2) Preparation of liquid mulch film: Add 0.015kg polyacrylamide, 0.005kg soluble starch, 4.7ml Tween (80), 15.4ml glycerin, 0.005kg neutral black BL to the above mixed solution, and heat up to 80°C , stirring at 110r / min for 0.5h, a high tensile strength degradable liquid mulch can be obtained. Wherein, the tensile strength test data is shown in Table 1.

[0040] Table 1 Tensile Strength Test Results

[0041]

[0042] Note: The data test is based on GB13022-91, making dumbbell-shaped samples. The sample width is 15mm, the original gaug...

Embodiment 2

[0044] Preparation of low moisture permeability mulch:

[0045] (1) Preparation of mixed aqueous solution of polyvinyl alcohol, wood calcium, and silica sol: add 300kg of water to the reaction kettle, measure and add 0.063kg of polyvinyl alcohol, 0.027kg of wood calcium, and 33ml of silica sol (20nm) in sequence, set at 60r / min at 60°C Stir at constant temperature for 2 h, then cool down to room temperature to obtain a mixed solution.

[0046] (2) Preparation of liquid film: Add 0.015kg polyacrylamide, 0.005kg soluble starch, 4.7ml Tween (80), 15.7ml glycerin, 0.005kg black TBRN to the above mixed solution, heat up to 80°C, Stir at 110r / min for 0.75h to obtain a degradable liquid mulch film.

[0047] The film obtained above was subjected to the determination of the water vapor transmission coefficient (according to GB1037-88, using the quasi-cup method. Put 5g of anhydrous calcium chloride in the weighing bottle, seal the liquid film with paraffin on the mouth of the conical bo...

Embodiment 3

[0049] Preparation of composite liquid mulch film:

[0050] (1) Preparation of mixed aqueous solution of polyvinyl alcohol, wood calcium, and silica sol: add 300kg of water to the reaction kettle, add 0.050kg of polyvinyl alcohol, 0.048kg of wood calcium, and 50ml of silica sol (15nm) in sequence, and place at 55r / min at 60°C Stir at constant temperature for 2 h, then cool down to room temperature to obtain a mixed solution.

[0051] (2) Preparation of liquid mulch film: Add 0.015kg of polyacrylamide, 0.005kg of soluble starch, 4.7ml of Tween (80), 15.7ml of glycerin, 0.005kg of neutral black BL and black TBRN mixture into the above mixed solution , heated up to 80°C, stirred at 120r / min for 1h, and a degradable liquid mulch film could be obtained.

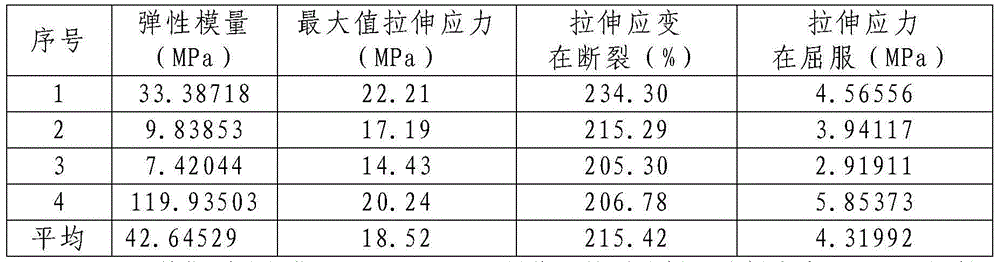

[0052] According to GB1037-88, the water vapor transmission coefficient of the film obtained above was measured by the pseudo-cup method, and the average result was 0.163g / m 2 d. The tensile strength test data are shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com