Preparation method of high-strength iron-base alloy and high-strength iron-base alloy cutting pick

An iron-based alloy, high-strength technology, applied in cutting machinery and other directions, can solve the problems of low core toughness, high white spot sensitivity, difficult to grasp the heat treatment process, etc., to achieve the effect of small environmental load and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

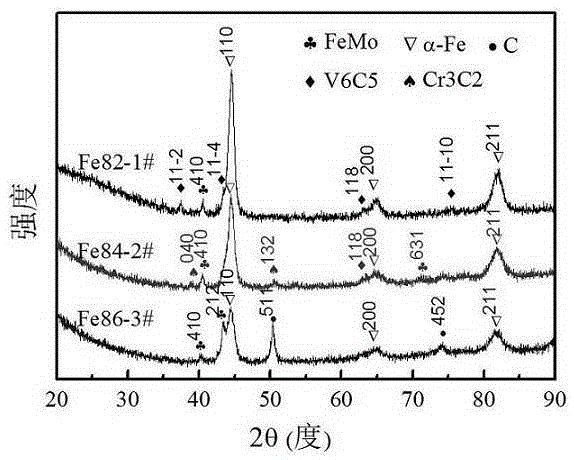

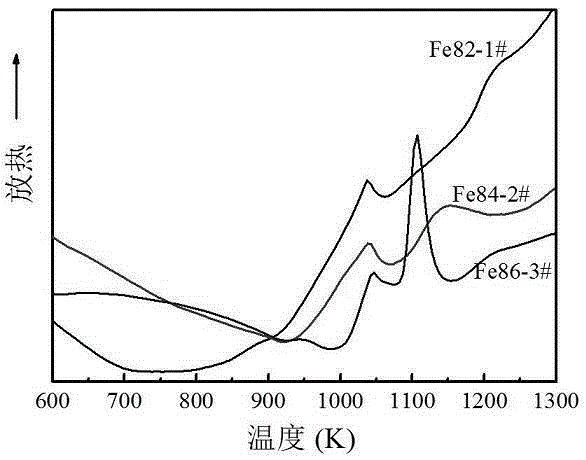

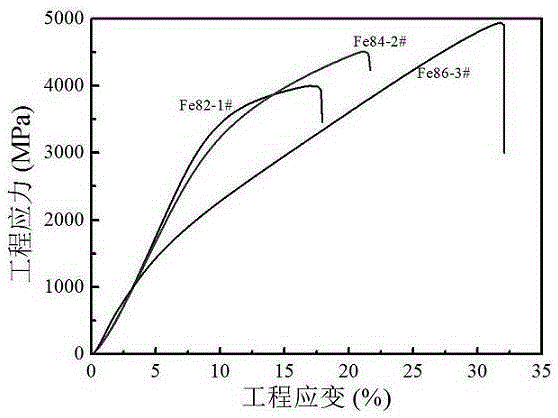

[0021] Embodiment 1: prepare Fe 82 Cr 4 Mo 5 V 4 C 5 (Expressed by Fe82-1#) alloy, Fe 84 Cr 4 Mo 5 V 2 C 5 (Expressed by Fe84-2#) alloy, Fe 86 Cr 4 Mo 5 C 5 (expressed as Fe86-3#) alloy

[0022] Convert the atomic percentage into weight percentage, weigh the raw materials of pure metal Fe, Cr, Mo, V and C with a purity of more than 99% in proportion, and set aside.

[0023] Put the mixed material according to the above composition ratio in the water-cooled copper crucible of the electric arc melting furnace, and first vacuumize to 5*10 -5 Pa, then fill it with argon until the pressure is 600mbar, and continue melting for 5 minutes after melting. After the alloy is cooled to solidification with the copper crucible, it is quickly turned over and smelted repeatedly for 3-5 times to obtain an alloy ingot with uniform composition. The alloy ingot is taken out and polished to remove the oxide film on the surface, and then placed in an aluminum oxide crucible for melti...

Embodiment 2

[0028] Embodiment 2: prepare Fe 84 Cr 4 Mo 5 V 2 C 5 pick

[0029] Five raw materials, including 3.75% Cr, 8.66% Mo, 1.08% C, 1.84% V, and 84.67% Fe, were mixed and put into the water-cooled copper crucible of the electric arc melting furnace. First vacuum the arc melting furnace to 5*10 -5 Pa, and then filled with argon to a pressure of 600mbar. Then the mixed raw materials are heated, melted and then smelted for another 5 minutes. After the alloy is cooled to solidification with the copper crucible, it is quickly turned over and smelted repeatedly for 3-5 times to obtain an alloy ingot with uniform composition. The alloy ingot is taken out and polished to remove the oxide film on the surface, and then placed in an aluminum oxide crucible for melting again. After the alloy is completely smelted, the melted alloy melt is poured into the pre-placed copper mold for preparing picks . After the alloy is completely cooled, it is taken out from the copper mold to obtain Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compression breaking strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com