Large-area perovskite thin sheet and preparation and application thereof

A perovskite, large-area technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., can solve problems such as perovskite crystal optoelectronic devices that have not yet appeared, achieve low defect density of states, and facilitate processing , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of large-area perovskite flakes is as follows.

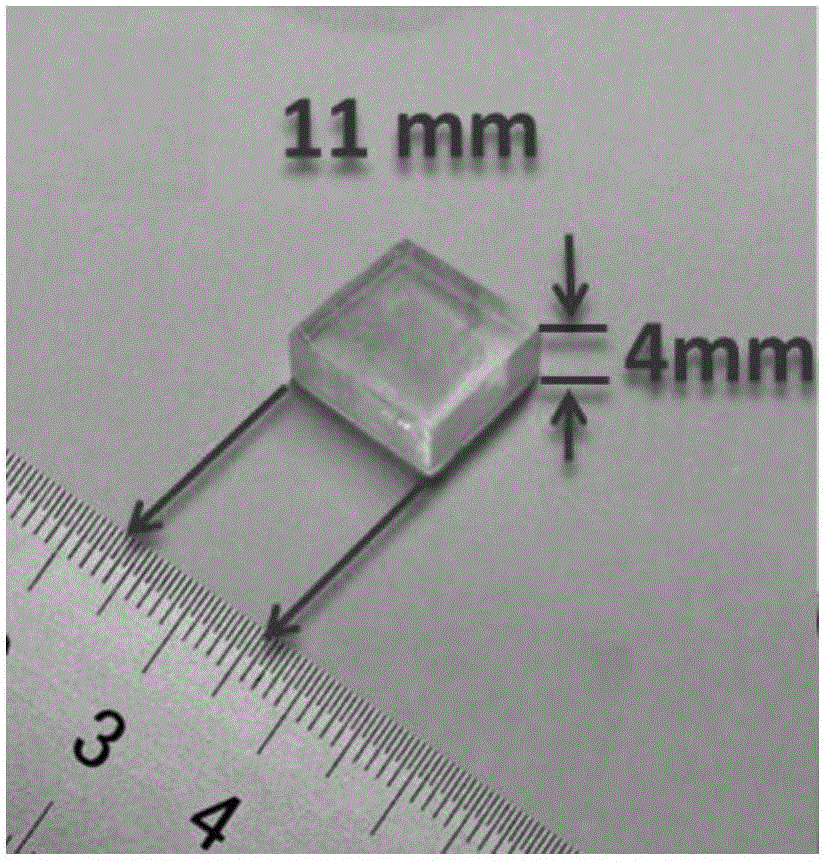

[0044] 1. Using the method of continuous growth, the fresh CH 3 NH 3 I and PbI 2 The mixed solution was continuously injected into the crystal growth container to maintain the crystal growth solution at a constant concentration to ensure the continuity and uniformity of the crystal growth process, so as to obtain a single crystal CH with a size of 15 mm × 15 mm × 5 mm. 3 NH 3 PB 3 ;

[0045] 2. Using the method of mortar cutting, in which the speed of the sand line movement is 3mm / s, the large-size perovskite crystal is cut to obtain an area of 200mm 2 , perovskite single crystal flakes with a thickness of 100 μm;

[0046] 3. Use ultrasonic cleaning to remove the mortar on the surface of the perovskite single wafer;

[0047] 4. Using a mechanical polishing machine, the two sides of the perovskite sheet are polished to remove the damaged layer during the cutting process and increase the flatness of...

Embodiment 2

[0054] The preparation of large-area perovskite flakes is as follows.

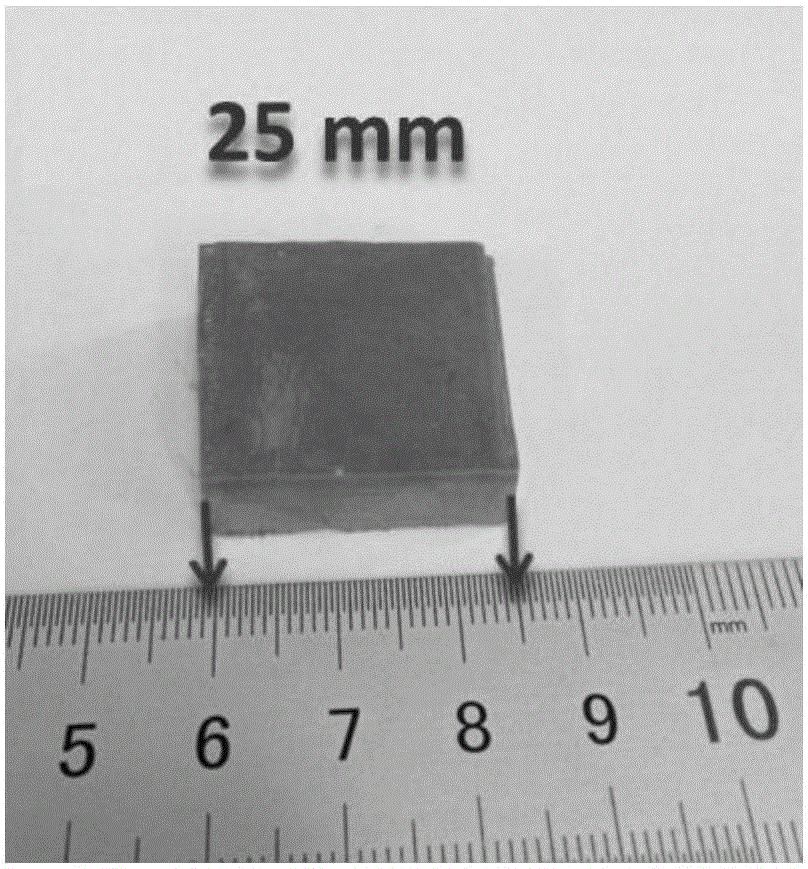

[0055] 1. Using the method of continuous growth, the fresh CH 3 NH 3 Br and PbBr 2 The mixed solution is continuously injected into the crystal growth container to maintain the crystal growth solution at a constant concentration to ensure the continuity and uniformity of the crystal growth process to obtain a CH with a size of 50mm×50mm×15mm. 3 NH 3 PbBr 3 crystal;

[0056] 2. Using the sand wire cutting method, in which the speed of the sand wire movement is 3mm / s, the large-size perovskite crystal is cut to obtain an area of 500mm 2 , perovskite flakes with a thickness of 500 μm;

[0057] 3. Use ultrasonic cleaning to remove the mortar on the surface of the perovskite single wafer;

[0058] 4. Using a mechanical polishing machine, the two sides of the perovskite sheet are polished to remove the damaged layer during the cutting process and increase the flatness of the perovskite single crystal su...

Embodiment 3

[0065] The preparation of large-area perovskite flakes is as follows.

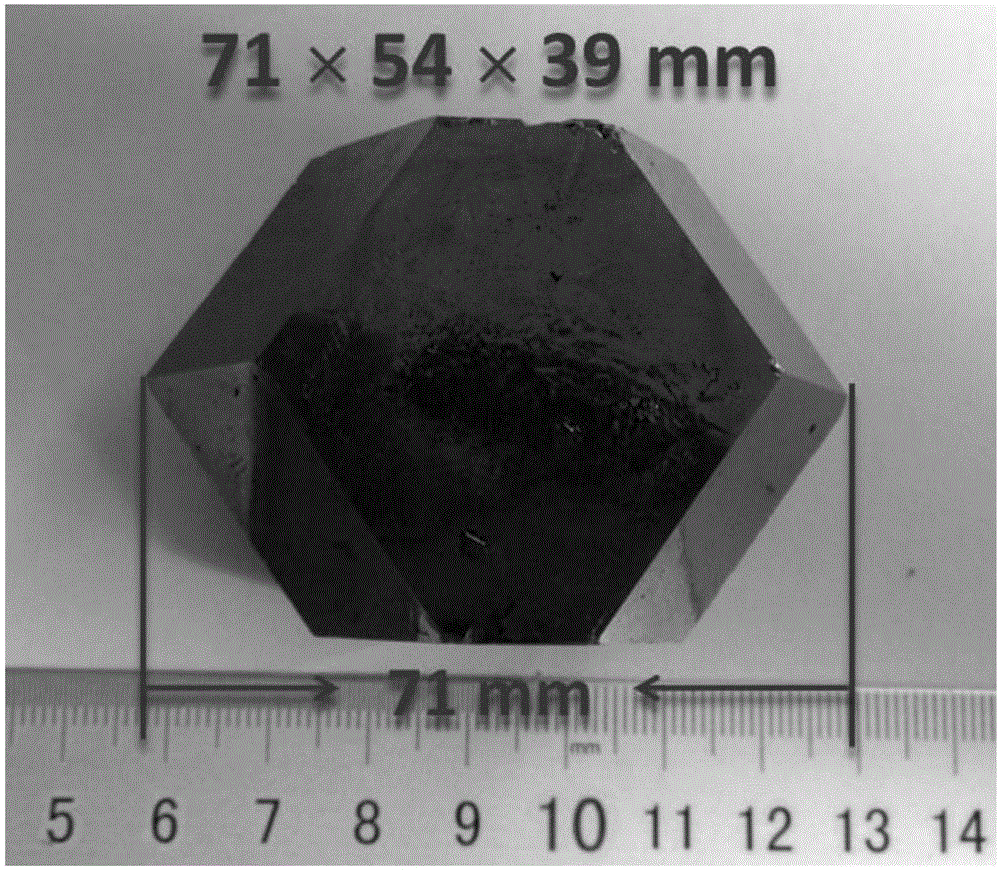

[0066] 1. Using the method of continuous growth, the fresh CH 3 NH 3 Cl and PbCl 2 The mixed solution is continuously injected into the crystal growth container to maintain the crystal growth solution at a constant concentration to ensure the continuity and uniformity of the crystal growth process, so as to obtain a single crystal CH with a size of 20mm×20mm×10mm 3 NH 3 PbCl 3 ;

[0067] 2. Using the method of diamond wire cutting, in which the speed of diamond wire movement is 5mm / s, the large-size perovskite single crystal is cut to obtain an area of 400mm 2 , perovskite single crystal flakes with a thickness of 400 μm;

[0068] 3. Using a mechanical polishing machine, the two sides of the perovskite sheet are polished to remove the damaged layer during the cutting process and increase the flatness of the perovskite single crystal surface, so as to facilitate the assembly of subsequent devices. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com